Abstract

Solvents that produce cellulose nanocrystals (CNCs) and promote cellulose fibrillation are of current interest. In this work, CNCs were fabricated from cotton at 80 and 100 °C using deep eutectic solvents (DESs) having choline chloride/oxalic acid dihydrate (OA) ratios of 1:1, 1:2 and 1:3. To investigate the side effects of the fabrication, the crystal structure and morphology of micro-sized treated cellulose together with nano-sized CNCs were analyzed by X-ray diffraction, field emission scanning electron microscopy and atomic force microscopy. OA promoted the formation of carboxyl groups on the C6 positions of molecules on the hydrophilic (1–10) lattice planes, causing extensive fibrillation of cellulose and disruption of surface layers on (110) and (200) planes. Lower crystallinity and lamellar structures for CNCs with mild treatment were observed after mechanical disintegration and subsequent lyophilization, which was ascribed to van der Waals forces and hydrogen bonding between adjacent crystalline cellulose chains, accelerating the self-assembly into cellulose macrofibrils. This work is discussed in light of cellulose supramolecular structures that are modified from CNC fabrication via DES treatment, with a view to enhancing the efficacy of treatment by understanding the variations that arise in cellulose structure from a green solvent.

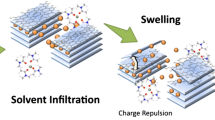

Graphical abstract

Similar content being viewed by others

References

Cael JJ, Koenig JL, Blackwell J (1974) Infrared and raman spectroscopy of carbohydrates: part IV. identification of configuration-and conformation-sensitive modes for d-glucose by normal coordinate analysis. Carbohydr Res 32:79–91

Chen L, Zhu JY, Baez C, Kitin P, Elder T (2016) Highly thermal-stable and functional cellulose nanocrystals and nanofibrils produced using fully recyclable organic acids. Green Chem 18:3835–3843. https://doi.org/10.1039/C6GC00687F

Cuba-Chiem LT, Huynh L, Ralston J, Beattie DA (2008) In situ particle film ATR FTIR spectroscopy of carboxymethyl cellulose adsorption on talc: binding mechanism, pH effects, and adsorption kinetics. Langmuir 24:8036–8044

Deng M, Zhou Q, Du A, van Kasteren J, Wang Y (2009) Preparation of nanoporous cellulose foams from cellulose-ionic liquid solutions. Mater Lett 63:1851–1854

Deville S, Saiz E, Nalla RK, Tomsia AP (2006) Freezing as a path to build complex composites. Science 311:515–518

Ding S-Y, Himmel ME (2006) The maize primary cell wall microfibril: a new model derived from direct visualization. J Agric Food Chem 54:597–606. https://doi.org/10.1021/jf051851z

Fang W, Arola S, Malho JM, Kontturi E, Linder MB, Laaksonen P (2016) Noncovalent dispersion and functionalization of cellulose nanocrystals with proteins and polysaccharides. Biomacromolecules 17:1458–1465. https://doi.org/10.1021/acs.biomac.6b00067

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896. https://doi.org/10.1007/s10570-013-0030-4

Han J, Zhou C, Wu Y, Liu F, Wu Q (2013) Self-assembling behavior of cellulose nanoparticles during freeze-drying: effect of suspension concentration, particle size, crystal structure, and surface charge. Biomacromolecules 14:1529–1540

Hebeish A, Hashem M, Shaker N, Ramadan M, El-Sadek B, Hady MA (2009) New development for combined bioscouring and bleaching of cotton-based fabrics. Carbohydr Polym 78:961–972

Holzwarth U, Gibson N (2011) The Scherrer equation versus the ‘Debye-Scherrer equation’. Nat Nanotechnol 6:534

Hori R, Wada M (2005) The thermal expansion of wood cellulose crystals. Cellulose 12:479

Idström A, Brelid H, Nydén M, Nordstierna L (2013) CP/MAS 13C NMR study of pulp hornification using nanocrystalline cellulose as a model system. Carbohydr Polym 92:881–884. https://doi.org/10.1016/j.carbpol.2012.09.097

Ilharco LM, Garcia AR, Lopes da Silva J, Vieira Ferreira LF (1997) Infrared approach to the study of adsorption on cellulose: influence of cellulose crystallinity on the adsorption of benzophenone. Langmuir 13:4126–4132

Isogai A (2013) Wood nanocelluloses: fundamentals and applications as new bio-based nanomaterials. J wood Sci 59:449–459

Isogai A, Saito T, Fukuzumi H (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3:71–85

Iwamoto S, Nakagaito AN, Yano H (2007) Nano-fibrillation of pulp fibers for the processing of transparent nanocomposites. Appl Phys A 89:461–466

Kettering J, Conrad C (1942) Quantitative determination of cellulose in raw cotton fiber. Simple and rapid semimicro method. Ind Eng Chem Anal Ed 14:432–434

Kim D-Y, Nishiyama Y, Wada M, Kuga S, Okano T (2001) Thermal decomposition of cellulose crystallites in wood. Holzforschung 55:521–524

Klemm D, Kramer F, Moritz S, Lindström T, Ankerfors M, Gray D, Dorris A (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem Int Ed 50:5438–5466

Kuribayashi T, Ogawa Y, Rochas C, Matsumoto Y, Heux L, Nishiyama Y (2016) Hydrothermal transformation of wood cellulose crystals into pseudo-orthorhombic structure by cocrystallization. ACS Macro Lett. pp 730–734. https://doi.org/10.1021/acsmacrolett.6b00273

Laitinen O, Ojala J, Sirviö JA, Liimatainen H (2017) Sustainable stabilization of oil in water emulsions by cellulose nanocrystals synthesized from deep eutectic solvents. Cellulose 24:1679–1689. https://doi.org/10.1007/s10570-017-1226-9

Lee CM, Chen X, Weiss PA, Jensen L, Kim SH (2016) Quantum mechanical calculations of vibrational sum-frequency-generation (SFG) spectra of cellulose: dependence of the CH and OH peak intensity on the polarity of cellulose chains within the SFG coherence domain. J Phys Chem Lett 8:55–60

Li D, Henschen J, Ek M (2017) Esterification and hydrolysis of cellulose using oxalic acid dihydrate in a solvent-free reaction suitable for preparation of surface-functionalised cellulose nanocrystals with high yield. Green Chem 19:5564–5567. https://doi.org/10.1039/c7gc02489d

Ling Z, Zhang X, Yang G, Takabe K, Xu F (2018) Nanocrystals of cellulose allomorphs have different adsorption of cellulase and subsequent degradation. Ind Crops Prod 112:541–549

Liu Y, Chen W, **a Q, Guo B, Wang Q, Liu S, Liu Y, Li J, Yu H (2017) Efficient cleavage of lignin-carbohydrate complexes and ultrafast extraction of lignin oligomers from wood biomass by microwave-assisted treatment with deep eutectic solvent. Chemsuschem 10:1692–1700. https://doi.org/10.1002/cssc.201601795

Martínez-Sanz M, Lopez-Rubio A, Lagaron JM (2011) Optimization of the nanofabrication by acid hydrolysis of bacterial cellulose nanowhiskers. Carbohydr Polym 85:228–236

Matthews JF, Skopec CE, Mason PE, Zuccato P, Torget RW, Sugiyama J, Himmel ME, Brady JW (2006) Computer simulation studies of microcrystalline cellulose Iβ. Carbohydr Res 341:138–152

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev. 40:3941–3994

Morais JPS, de Freitas Rosa M, Nascimento LD, do Nascimento DM, Cassales AR (2013) Extraction and characterization of nanocellulose structures from raw cotton linter. Carbohydr Polym 91:229–235

Nam S, French AD, Condon BD, Concha M (2016) Segal crystallinity index revisited by the simulation of X-ray diffraction patterns of cotton cellulose Iβ and cellulose II. Carbohydr Polym 135:1–9. https://doi.org/10.1016/j.carbpol.2015.08.035

Nechyporchuk O, Belgacem MN, Bras J (2016) Production of cellulose nanofibrils: a review of recent advances. Ind Crops Prod 93:2–25. https://doi.org/10.1016/j.indcrop.2016.02.016

Nishiyama Y, Langan P, Chanzy H (2002) Crystal structure and hydrogen-bonding system in cellulose Iβ from synchrotron X-ray and neutron fiber diffraction. J Am Chem Soc 124:9074–9082

Reddy N, Yang Y (2009) Properties and potential applications of natural cellulose fibers from the bark of cotton stalks. Bioresour Technol 100:3563–3569

Rosa MF, Medeiros ES, Malmonge JA, Gregorski KS, Wood DF, Mattoso LHC, Glenn G, Orts WJ, Imam SH (2010) Cellulose nanowhiskers from coconut husk fibers: effect of preparation conditions on their thermal and morphological behavior. Carbohydr Polym 81:83–92

Saito T, Nishiyama Y, Putaux J-L, Vignon M, Isogai A (2006) Homogeneous suspensions of individualized microfibrils from TEMPO-catalyzed oxidation of native cellulose. Biomacromolecules 7:1687–1691

Salminen R, Baccile N, Reza M, Kontturi E (2017) Surface-induced frustration in solid state polymorphic transition of native cellulose nanocrystals. Biomacromolecules. https://doi.org/10.1021/acs.biomac.7b00463

Selkälä T, Sirviö JA, Lorite GS, Liimatainen H (2016) Anionically stabilized cellulose nanofibrils through succinylation pretreatment in urea–lithium chloride deep eutectic solvent. ChemSusChem. pp 3074–3083. https://doi.org/10.1002/cssc.201600903

Sirviö JA, Visanko M, Liimatainen H (2015) Deep eutectic solvent system based on choline chloride-urea as a pre-treatment for nanofibrillation of wood cellulose. Green Chem 17:3401–3406. https://doi.org/10.1039/C5GC00398A

Sirviö JA, Visanko M, Liimatainen H (2016) Acidic deep eutectic solvents as hydrolytic media for cellulose nanocrystal production. Biomacromolecules 17:3025–3032. https://doi.org/10.1021/acs.biomac.6b00910

Sugiyama J, Okano T, Yamamoto H, Horii F (1990) Transformation of Valonia cellulose crystals by an alkaline hydrothermal treatment. Macromolecules 23:3196–3198

Tang X, Zuo M, Li Z, Liu H, **ong C, Zeng X, Sun Y, Hu L, Liu S, Lei T, Lin L (2017) Green processing of lignocellulosic biomass and its derivatives in deep eutectic solvents. Chemsuschem 10:2695. https://doi.org/10.1002/cssc.201701012

Zhbankov RG, Firsov SP, Buslov DK, Nikonenko NA, Marchewka MK, Ratajczak H (2002) Structural physico-chemistry of cellulose macromolecules. Vibrational spectra and structure of cellulose. J Mol Struct 614:117–125

Acknowledgments

The authors gratefully acknowledge financial support by National Key Research and Development Program of China (2017YFD0601004) and Chinese Scholarship Council (CSC No. 201706510045). We also appreciate Dr. Mohammad Saghayezhian of LSU Shared Instrument Facility for technical assistance with the XRD experiments.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ling, Z., Edwards, J., Guo, Z. et al. Structural variations of cotton cellulose nanocrystals from deep eutectic solvent treatment: micro and nano scale. Cellulose 26, 861–876 (2019). https://doi.org/10.1007/s10570-018-2092-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-2092-9