Abstract

Reinforced concrete (RC) frames with masonry infills can be encountered all over the world, especially in earthquake prone regions. Although masonry infills are usually not considered in the design process, in the case of seismic loading they are subjected to in-plane and out-of-plane forces that can act separately or simultaneously. In recent earthquakes it was observed that seismic loads can severely damage masonry infills or even cause their complete collapse, especially when the loads act simultaneously. Due to this, effects of interaction of in-plane and out-of-plane loads on seismic performance of masonry infills have received more attention recently. However, most of studies focus only on fully infilled frames, even though openings, such as windows and doors are essential parts of infills that substantially affect the seismic response of masonry infills. Therefore, this article presents the results of a comprehensive experimental study on nine full-scale traditional masonry RC frames infilled with modern hollow clay bricks for configurations with and without window and door openings under separate, sequential and combined in-plane and out-of-plane loading. Based on the results, a detailed comparison and interpretation for the different infill and loading configurations is presented. The test results clearly show the unfavourable influence of openings and combined loading conditions as well as the importance of the quality of execution of the circumferential mortar joint between infill and frame. The new findings can be used as a basis for the required development of innovative solutions to improve significantly the seismic performance of RC frames with masonry infills.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In modern construction practice, reinforced concrete (RC) frames with masonry infills constitute a large portion of commercial and residential multi-storey buildings. This is due to several reasons. Firstly, RC frame structures appropriately designed for seismic loading provide an excellent seismic performance due to high deformation and dissipation capacity. In addition to this, they are characterized by cost-efficient construction as their erection requires simple building methods and less skilled labour in comparison to steel structures. In most of the RC frame structures masonry infills are installed as interior or exterior walls, since they represent an environmentally friendly solution which has distinguished with high energy efficiency, significant fire resistance and excellent sound isolation. Further advantages of the utilization of this enclosure system in frame structures are its simple and economical construction process, durability and fulfilment of requirements of modern and attractive architecture.

In the current engineering practice, RC frames represent load-bearing structures that need to be designed in accordance with building codes that consider seismic actions. However, masonry infills are generally considered as non-structural elements that are neglected in the design process due to the lack of simple analytical design models (Marinković 2018c). This assumption is justified for vertical loads, as masonry infills are installed after the construction of the surrounding frames without vertical load transfer between frame and infill, but it is not valid for lateral loads induced by seismic excitation, since masonry infills are traditionally installed in direct contact to the frame and the remaining gaps between infill and frame are filled with mortar. Under seismic loading conditions, RC frames with relatively low stiffness deflect and activate the much stiffer masonry infills, which results in a complex interaction between the RC frame and infills. This interaction was described and investigated by several authors (Moghaddam and Dowling 1987; Mehrabi et al. 1996; Crisafulli 1997; Chrysostomou and Asteris 2012).

Generally, the contribution of infills leads to a significant increase of the horizontal stiffness of the overall structural system and the overall capacity of structures is strongly dependant on the regularity of their distribution in plan and elevation (Di Trapani et al. 2015). On one side, regularly distributed masonry infills may reduce the deformation demand and improve the energy dissipation capacity of infilled frame structures, as observed in past earthquakes (Decanini et al. 2005, 2012). On the contrary, an asymmetric distribution of masonry infills that are not considered in the design can cause additional torsional effects, which introduce additional forces, especially in concrete columns of the outer frames (Fardis 2006). Furthermore, the increase of the lateral stiffness of the structure caused by the activation and contribution of masonry infills decreases the natural period of vibration of the structure and leads to an increase of accelerations and inertia forces acting on the structure. However, masonry infills are characterized by a rather stiff and brittle response resulting in partial or complete failure and thus a sudden loss of resistance at lower drift values. This leads to a transfer of the high forces previously attracted and carried by the infilled frames to the bare frames with lower resistances (Marinković 2018c). Moreover, failure of overloaded masonry infills might cause additional critical torsional effects, even if the masonry infills are arranged regularly (Butenweg et al. 2019). To make matters worse, in addition to in-plane drift demands, masonry infills are also subjected to seismic forces perpendicular to the wall plane, since the earthquake actions affect the structure in all three spatial directions. Therefore, in-plane and out-of-plane loading can act separately or simultaneously on single masonry infills.

Considering the shortcomings of traditionally infilled RC frames and the combined seismic action effects, it is not surprising that these structures demonstrated a huge vulnerability in recent earthquake events in Lorca (Spain, 2011), L’Aquila (Italy, 2009), Emilia Romagna (Italy, 2012), Central Italy (2016) and Albania (2019). The documented observations from field campaigns show that most of the damage affected non-structural elements, i.e., exterior masonry infills and internal partition walls, as they experienced typical in-plane, out-of-plane and mixed failure mechanisms (Ricci et al. 2011; Braga et al. 2011; Hermanns et al. 2014; Manfredi et al. 2014; Perrone et al. 2019; Marinković et al. 2022). Furthermore, significant damage in RC elements and beam-column joints due to local interaction with infill panels and poor reinforcement detailing was reported as well, but to a smaller extent (Ricci et al. 2011; Hermanns et al. 2014; Manfredi et al. 2014; Marinković et al. 2022), while complete collapses of buildings occurred mostly due to irregularities in plan and elevation (Ricci et al. 2011; Hermanns et al. 2014; Manfredi et al. 2014; Marinković et al. 2022).

The influence on the structural behaviour of frame structures due to masonry infills has been already recognized in the middle of the 20th century (Ockleston 1955; Read 1965). Numerous research projects have been conducted to study the unpredictable seismic response of frame structures with masonry infills and to prevent the occurrence of damage. Most of the experimental and numerical studies were focused on the investigation of pure in-plane loading to gain a better understanding of the frame-infill interaction and its influence on the overall structural seismic response. Based on the results of the first experimental studies, Polyakov (1960) and Smith (1966) suggested the idealization of infilled frames as braced frames with diagonal compression struts representing the contribution of the masonry infill. However, the results of numerous studies carried out (Mainstone 1971; Paulay and Priestley 1992; Angel et al. 1994; Mehrabi et al. 1996; Flanagan and Bennett 1999a; Chrysostomou and Asteris 2012) showed that the level of contribution of masonry infills cannot be easily determined as it depends on the specific failure modes of the masonry infill or the surrounding frame. According to Crisafulli (1997) and El-Dakhakhni et al. (2003) the dominant failure modes of masonry infills subjected to in-plane loading are shear failure due to sliding, diagonal tension failure of the bricks along the diagonal compression struts and compression failure of the diagonal compression struts or the corners. In principle, the type of failure mode that might occur in the RC frame with masonry infill mostly depends on the mechanical and geometrical characteristics of the masonry infill, the design of the surrounding frame and the stress state induced in the infill panel. Potential failure modes of surrounding RC frames due to interaction effects are described in Crisafulli (1997).

The out-of-plane response of masonry infills was not so intensively investigated as in-plane loading. The formation of the arching effect was experimentally investigated by McDowell et al. (1956a, b). The performance of masonry infills under out-of-plane loading was further studied with experimental tests conducted by Dawe and Seah (1989a), Angel et al. (1994) and Flanagan and Bennett (1999b), among others. These authors investigated the parameters affecting arching action and concluded that masonry infills installed with full contact to the surrounding frame can reach several times higher out-of-plane capacities in comparison to the limited flexural capacity. Depending on the boundary conditions, out-of-plane loading can be resisted by one- or two-way arching mechanism. However, the lack of contact between the infill and frame caused by a poor quality execution of the mortared contact joint at the top of the wall (Manfredi and Masi 2014) or mortar shrinkage (Dafnis et al. 2002) can cause a tilting of the entire infill panel out of the frame. The influence of workmanship on out-of-plane response has also been recently addressed by Akhoundi et al. (2018).

Although the out-of-plane collapse of masonry infills is mainly expected to occur on upper storeys, masonry infills can also suffer substantial damage or complete failure due to interaction of in-plane and out-of-plane actions in lower storeys of buildings (Braga et al. 2011; Perrone et al. 2019; Marinković et al. 2022). Therefore, several experimental campaigns (Angel et al. 1994; Flanagan and Bennett 1999b; Calvi and Bolognini 2001; Da Porto et al. 2013, Furtado et al. 2016; Morandi et al. 2017; Akhoundi et al. 2018; Ricci et al. 2018a,b; Butenweg et al. 2019; De Risi et al. 2019; ** between the bricks is clearly visible. The contact length between rotated bricks corresponds approximately to the overlap** length of 0.4 h. The specific load-resisting mechanism with brick rotations is activated due to the combination of strong bricks, non-mortared head joints and a strong interaction between the infill and the top beam (caused by high quality mortar application between frame and infill). Figure 18 shows an example of the vertical deflection of the top beam at different levels of in-plane drifts in test T3 with maximum displacements of 15 mm in the middle of the beam, that exceed the maximum beam deflection (L/250 = 12 mm) according to EN 1992–1-1 (2004), that confirms pronounced frame-infill interaction in fully infilled frames. The deflection allows an extension of the compression strut and delays the occurrence of diagonal tension failures in the bricks along the strut. At lower drift values, stepwise cracking with bond failure in the bed joints and opening of the non-mortared head joints takes part. At higher in-plane drifts, the rotation of the bricks with extension of head and bed joints is more pronounced, whereas the bricks experience only minor cracks up to the drift of 1.0% when crushing of thin brick webs and falling of outer shells starts. The level of damage at around 1.0% of in-plane drift, with significant damage to the mortar joints and development of cracks in the bricks corresponds to the significant damage limit state conditions defined by Morandi et al. (2018b). According to Morandi et al. (2018b), human lives are not threatened at this point, due to the limited weight of masonry portions falling down. However, demolishing and reconstruction of the entire infills is a more convenient solution because repairment could be too expensive. At the maximum attained in-plane drifts, the damage level is much higher and it should be classified as a near collapse limit state (NCLS), in which the cracking in mortar joints is extensive and crushing and spalling of bricks are widespread, but the collapse still does not occur, as described by Morandi et al. (2022). Table 13 shows a concentration of the damage in the middle row of the infill in test T2 and next to columns in test T3 in final in-plane load stages, that might be attributed to the effect of simultaneously applied in- and out-of-plane loads in test T3. The observed stepwise cracking at lower drifts in the tests T2 and T3 was also confirmed by Crisafulli (1997) for infills with low to medium aspect ratios in which the shear stresses are decisive.

However, in contrast to the obtained results numerous experimental campaigns and computational studies (Liauw and Kwan 1985; Crisafulli 1997; Al-Chaar 2002; Stylianidis 2012, Asteris et al. 2013; Butenweg et al. 2019) described the in-plane response of masonry infills at higher drifts by a separation of the masonry infill from the surrounding frame in the unloaded corners and an activation of concentrated compression struts between the infill corners in contact to the frame (Fig. 17b). This illustrates the complex behaviour of RC frames with masonry infill, which is, among other aspects, particularly dependent on both the geometry and the stiffness ratio between the RC frame and the panel, as well as on the ratio of brick and joint strengths.

6.2 RC infilled frames with window openings (T5, T6)

The results in Table 13 show that first stepwise cracks below and above window occur at a drift of about 0.05%. With increasing in-plane drifts, diagonal compression struts separated by expanded head and bed joints are generated in both infill piers and the bricks rotate along the struts and the compressive forces are transferred over the overlap** length of 0.4 h (Fig. 19a). Similar to the fully infilled frames, the struts are uniformly distributed in each pier due to the strong bricks, non-mortared head joints and a strong interaction between the infill and the top beam. The interaction causes vertical deflections of the top beam, which are shown in Fig. 19b for the test T5 for a load application from the left to the right. At higher in-plane drifts the cracks widen and stepped cracks propagate through the joints in both infill piers. The in-plane response is strongly influenced by the coupling effect provided by the lintel beam above window opening, which connects the two infill piers separated by the window opening and allows them to deform together. This beneficial coupling effect was also reported by da Porto et al. (2020), who recognized that the presence of the lintel beam above opening reduces the relative rotation of the two masonry piers under cyclic in-plane loading. As it is described in Sects. 4.2.2 and 4.3.2 and summarized in Table 13, masonry infills with window openings suffer more damage at smaller in-plane drifts in comparison to the fully infilled frames. Due to the interrupted compression struts along the wall diagonals, detachment of infill parts next to the window opening already occurs at about 0.8% of drift. In addition to this, progressive crushing of the thin webs of the bricks and falling off of outer shells of bricks is observed at this load stage. The damage at this drift level (Δ ~ 0.8%) goes in line with the description of the significant damage limit state conditions, proposed by Morandi et al. (2018b). As shown in Table 13, the complete detachment of infill parts next to the window opening combined with a substantial damage to the bricks leads to the failure in both tests, at the maximum attained in-plane drifts.

6.3 RC infilled frames with door openings (T8, T9)

The results in Table 13 show that first stepwise cracks in the lower parts of the two piers occur at a drift level of about 0.2%. The formation of these cracks reduces the stiffness and increases the energy dissipation represented by wider hysteretic loops (Figs. 11, 12). The specific load-resisting mechanism for masonry infills with door openings loaded from the left to the right is shown in Fig. 20a. Due to the door opening the compression struts are steeper and the formation takes place on the left side in the lower wall area and on the right side in the upper wall area. The damage on the left side is characterized by a diagonal shear crack through joints and bricks, whereas on the right side stepwise cracks are generated along the compression struts. As already described for the infills without openings (T2, T3) and with window openings (T5, T6) a vertical deflection of the top beam takes place. The deflection of the top beam is shown for the maximum horizontal force in Fig. 20b. At in-plane drifts larger than 0.8% damage propagates further in both infill piers and the top beam experiences smaller deflection as a complete formation of the compression struts is no longer possible. This drift level (Δ ~ 0.8%) can be also set as a limit value for the significant damage limit state introduced by Morandi et al. (2018b). Table 13 shows the crack and damage pattern at the ultimate drifts for both tests, characterized by the detachment of almost triangular parts of the piers separated through diagonal cracks. Although the same failure developed in both infills with door opening, specimen T9 collapsed earlier due to the influence of simultaneously applied out-of-plane loading.

6.4 RC infilled frames under pure out-of-plane loading (T1, T4, T7)

Table 14 comprises the results for all pure out-of-plane tests. For each test, the crack pattern of the first visible crack, the maximum out-of-plane force and displacement are provided.

The first cracks occur at rather high levels of total out-of-plane force in all out-of-plane tests, due to the formation of a strong vertical arching effect as the dominant load-resisting mechanism. The out-of-plane displacement fields in Table 15 show additional horizontal arching effects in test T1 and T4, whereby the arching effect in T4 is limited to the continuous wall sections above and below the window opening. The specimens in test T1 and T4 collapsed in an explosion-like manner due to the stability failure of the compressed webs in the brick. This is in line with observations by Crisafulli (1997), that a sudden and occasionally “explosive” compressive failure can be expected to occur in infills made of hollow masonry units made of brittle materials with high strength to compensate the large void ratio. In test T7 the failure is caused by cracking and crushing of bricks close to the supporting beams at top and bottom.

As shown in Table 12 and Table 14, the masonry infill with window opening has a similar initial stiffness and provides the highest out-of-plane capacity of all tests. This result seems surprising at a first glance, but corresponds to the findings of Di Domenico et al. (2021), who concluded that the intuitive reduction of out-of-plane capacity may not always take place in case of masonry infills with window openings. The authors explained this with the model of Dawe and Seah (1989a) which is based on the principle of the virtual work. According to Di Domenico et al. (2021), the presence of centric window opening causes reduction of both internal and external work, but external work is expected to reduce more. Due to this, a larger pressure is needed to generate the equal amount of external work which results in higher out-of-plane capacity of masonry infill with window opening. The similar was concluded by Griffith and Vaculik (2007). Furthermore, Anić et al. (2020) attributed the similar out-of-plane capacities of solid masonry infills and masonry infills with window openings to the presence of lintel beams. In their studies, Anić et al. (2018) observed that the lintel can accumulate higher compressive stresses and thus increase the out-of-plane capacity. In addition to this, the crack pattern for specimen T4 (Table 14) is also in agreement with experimental results provided by Akhoundi et al. (2018) (Fig. 21a). Sepasdar (2017) investigated infill panels with openings arranged without lintel beams and reported about a reduced out-of-plane capacity and a different crack distribution as shown in Fig. 21b. This illustrates the detrimental behaviour when the lintel beam is not installed. Moreover, Furtado et al. (2021) observed an increase of the initial stiffness of infills with openings due to RC lintels in their experimental campaign.

6.5 Aspects of in-plane and out-of-plane load interaction

6.5.1 Fully infilled RC frames

The out-of-plane capacity for fully infilled RC frames decreased two times due to prior in-plane damage in test T2 and for simultaneous loading in test T3. Both results are in good agreement with tests on masonry infills under sequential loadings carried out by da Porto et al. (2013, 2020) and Morandi et al. (2017), who identified the formation of a stable two-way arching effect. In contrast, a two-way arching mechanism was not obtained in tests with sequential and simultaneous loading condition by Butenweg et al. (2019), due to a weak mortar joint at top and bottom caused by vertically perforated clay bricks with a high percentage of wide voids. The mortar joint was almost completely destroyed due to in plane-loading and a tilting of the entire infill panel took place. The influence of the mortar joint is further illustrated by the distribution of the contact stresses in Fig. 22. In test T3, the strong connection of infill to the frame prevents the gap** and provides the full contact (Fig. 22a). On the other side, the gap** in unloaded corners and damaged mortar joint cause significant reduction of contact between infill and frame in simultaneous loading test of Butenweg et al. (2019) (Fig. 22b).

Contact stresses for simultaneous in-plane and out-of-plane loading with full contact in test T3 (a) and with partial contact with damaged mortar joint (Butenweg et al. 2019) (b)

6.5.2 Infilled RC frames with openings

The high out-of-plane capacities of infills with openings decreased by a factor of 3.7 due to the crack pattern caused by prior in-plane loading in tests T5 and T8. The damage pattern shows the emergence of unstable triangular-like areas with increasing out-of-plane displacements adjacent to the openings. However, these areas did not completely fall out of wall plane most likely due to interlocking effects in the cracks that still allow the formation of a vertical arching effect under static loading conditions, as also reported by da Porto et al. (2020). Based on the observations in recent earthquakes it can be expected that the unstable areas will fall out due to inertia forces during a seismic excitation. The simultaneous test T6 on the infill with window opening led to a similar behaviour with locally increased out-of-plane displacements in the cracked areas around the opening. The test T9 illustrated the adverse effect of in- and out-of-plane load interaction due to a total collapse caused by a rigid body movement of one infill pier. Based on the results it is most likely to expect larger seismic vulnerability of masonry infills with openings subjected to combined in-plane and out-of-plane loading. Even if the mortar joint connections between infill and frame are strong enough to prevent a total collapse mechanism, in-plane cracking induces unstable panel parts next to openings. Similar observations with respect to in-plane cracking patterns in infills with openings have been made by Stavridis (2009), Tasnimi and Mohebkhah (2011) and Mansouri et al. (2014), among others. Their results show that the cracked and unstable infill areas next to openings tend to gradually fall out-of-plane even if they are loaded only in-plane. The detrimental crack patterns observed in this study (Fig. 23) are in good agreement with crack patterns observed in real earthquakes (Braga et al. 2011; Vicente et al. 2012; Nam et al. 2019).

7 Conclusions

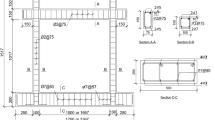

This article presents the results of an experimental study on nine RC frames infilled with high thermal insulating clay bricks with a thickness of 300 mm. The investigation comprises solid masonry infills, masonry infills with window and door openings under separate, sequential and combined in-plane and out-of-plane cyclic loading conditions. The test campaign allows the comparison of the performance of different infill typologies and loading conditions. Special attention was paid on the execution of the top joint, which was carefully filled with thin layer mortar. This leads to perfect and strong boundary conditions, which definitely cannot be assumed on all construction sites.

The results of the pure out-of-plane tests show that both solid infills and infills containing window and door openings exhibit a high level of out-of-plane capacities due to the strong arching effect based on the low slenderness ratio and the stable connection between the infill panel to the top and bottom beam. A significant reduction in stiffness and capacity occurs if the infilled frames have previously been subjected to cyclic in-plane loading. In this case the out-of-plane capacities were reduced about 2 times for the fully infilled frame and 3.7 times for the infilled frames with openings. A further reduction takes place, if the in-plane load is simultaneously applied.

The results of the in-plane tests show for all configurations a strong interaction with formation of uniformly distributed multiple compression struts and rotation of the bricks along the struts. In case of infills with openings the formation of steeper struts takes only place in the piers left and right to the openings. This specific load-resisting mechanism is activated through the combination of strong bricks, non-mortared head joints and the deflection of the top beam. The resulting load-capacity curves show significant reductions of the in-plane capacities for infills with window openings, which are even more pronounced for infills with door openings compared to fully infilled RC frames caused by the interrupted diagonal compression struts. The tests with simultaneously applied loading on solid infills and infills with window opening show a low sensitivity of the in-plane behaviour due to out-of-plane loading. However, in case of the infill with door opening a rigid body movement occurs due to the loss of frame-infill connection at the top and the bottom.

Furthermore, the test results clarify that masonry infills with or without centrally positioned openings increase the lateral strength and even more the lateral initial stiffness compared to a bare frame. This indicates that such typologies can change the dynamic properties of the infilled RC structures and cause torsional effects that can lead to failure of the overall structure.

The main result of the experimental investigations carried out was that cracking occurs in the brittle masonry infills even at very small drift values. Furthermore, the maximum loads are already reached at drift values between 0.8 and 1.0%, at which the damage level is severe and infills are not repairable, so this corresponds to the significant damage state. Subsequently, cracking increases rapidly and uncontrollable local failures of highly loaded wall areas occur, especially in the case of masonry infills with openings. It should be noted that this result was only achieved with a perfect and careful execution of the circumferential connection joint between infill and frame, which does never exist in practice. The problem of filling the joints is even more pronounced if highly thermally insulating bricks with the percentages of void ratios greater than 50% are used, especially for bricks with wide void geometry (Butenweg et al. 2019). Therefore, innovative systems should be developed to achieve the required seismic safety. Promising approaches are based on the idea to decouple infill and frame (Marinković 2018c; Marinković and Butenweg 2019) or to integrate sliding surfaces (Morandi et al. 2018a), but they require further research and development to safely cover all configurations from fully infilled to partially infilled RC frames.

References

Akhoundi F, Vasconcelos G, Lourenço P (2018) Experimental out-of-plane behavior of brick masonry infilled frames. Int J Archit Herit 14(2):221–237. https://doi.org/10.1080/15583058.2018.1529207

Al-Chaar G, Lamb GE, Issa MA (2003) Effect of openings on structural performance of unreinforced masonry infilled frames. ACI Special Publications 211:247–262. https://doi.org/10.14359/12593

Al-Chaar G (2002) Evaluating strength and stiffness of unreinforced masonry infill structures (No.ERDC/CERL-TR-02–1). Engineer research and development center champaign il construction engineering research lab

Angel R, Abrams D, Shapiro D, Uzarski J, Webster M (1994) Behavior of reinforced concrete frames with masonry infills. Civil Engineering Studies, Structural Research Series No. 589, UILU-ENG-94–2005, Department of Civil Engineering, University of Illinois at Urbana Champaign

Anić F, Penava D, Abrahamczyk L, Sarhosis V (2020) A review of experimental and analytical studies on the out-of-plane behaviour of masonry infilled frames. Bull Earthq Eng 18(5):2191–2246. https://doi.org/10.1007/s10518-019-00771-5

Anić F, Penava D, Guljaš I, Sarhosis V, Abrahamczyk L, Butenweg C (2018a) The effect of openings on out-of-plane capacity of masonry infilled reinforced concrete frames. In: 16th European Conference on Earthquake Engineering, Thessaloniki, Greece

Asteris PG (2003) Lateral stiffness of brick masonry infilled plane frames. J Struct Eng 129(8):1071–1079. https://doi.org/10.1061/(ASCE)0733-9445(2003)129:8(1071)

Asteris PG, Antoniou ST, Sophianopoulos DS, Chrysostomou CZ (2011) Mathematical macromodeling of infilled frames: state of the art. J Struct Eng 137(12):1508–1517. https://doi.org/10.1061/(ASCE)ST.1943-541X.0000384

Asteris PG, Giannopoulos IP, Chrysostomou CZ (2012) Modeling of infilled frames with openings. Open Constr Build Technol J 6(1):81–91. https://doi.org/10.2174/1874836801206010081

Asteris PG, Cotsovos DM, Chrysostomou CZ, Mohebkhah A, Al-Chaar G (2013) Mathematical micromodeling of infilled frames: state of the art. Eng Struct 56:1905–1921. https://doi.org/10.1016/j.engstruct.2013.08.010

Binici B, Canbay E, Demirel İO, Aldemir A, Uzgan U, Eryurtlu Z, Yakut A (2018b) Seismic response of autoclaved aerated concrete masonry infill walls under in-plane and out-of-plane seismic demands. Ce/papers 2(4):241–245. https://doi.org/10.1002/cepa.814

Braga F, Manfredi V, Masi A, Salvatori A, Vona M (2011) Performance of non-structural elements in RC buildings during the L’Aquila, 2009 earthquake. Bull Earthq Eng 9(1):307–324. https://doi.org/10.1007/s10518-010-9205-7

Butenweg C, Marinković M, Salatić R (2019) Experimental results of reinforced concrete frames with masonry infills under combined quasi-static in-plane and out-of-plane seismic loading. Bull Earthq Eng 17(6):3397–3422. https://doi.org/10.1007/s10518-019-00602-7

Calvi GM, Bolognini D (2001) Seismic response of reinforced concrete frames infilled with weakly reinforced masonry panels. J Earthq Eng 5:153–185. https://doi.org/10.1080/13632460109350390

Cavaleri L, Zizzo M, Asteris PG (2020) Residual out-of-plane capacity of infills damaged by in-plane cyclic loads. Eng Struct 209:109957. https://doi.org/10.1016/j.engstruct.2019.109957

Chrysostomou CZ, Asteris PG (2012) On the in-plane properties and capacities of infilled frames. Eng Struct 41:385–402. https://doi.org/10.1016/j.engstruct.2012.03.057

Crisafulli FJ, Carr AJ, Park R (2000) Analytical modelling of infilled frames structures- A general review. Bull N Z Soc Earthq Eng 33(1):30–47. https://doi.org/10.5459/bnzsee.33.1.30-47

Crisafulli FJ (1997) Seismic behaviour of reinforced concrete structures with masonry infills. Department of Civil Engineering, University of Canterbury, Christchurch

da Porto F, Donà M, Verlato N, Guidi G (2020) Experimental testing and numerical modeling of robust unreinforced and reinforced clay masonry infill walls, with and without openings. Front Built Environ 6:591985. https://doi.org/10.3389/fbuil.2020.591985

Dafnis A, Kolsch H, Reimerdes H (2002) Arching in masonry walls subjected to earthquake motions. J Struct Eng, ASCE 128(2):153–159. https://doi.org/10.1061/(ASCE)0733-9445(2002)128:2(153)

Dawe JL, Seah CK (1989a) Out-of-plane resistance of concrete masonry infilled panels. Can J Civ Eng 16(6):854–864

Dawe JL, Seah CK (1989b) Behaviour of masonry infilled steel frames. Can J Civ Eng 16(6):865–876

da Porto F, Guidi G, Dalla Benetta M, Verlato N (2013) Combined in-plane/out-of-plane experimental behaviour of reinforced and strengthened infill masonry walls. In: Proceedings of the 12th Canadian masonry symposium, Vancouver, British Columbia

De Risi MT, Di Domenico M, Ricci P, Verderame GM, Manfredi G (2019) Experimental investigation on the influence of the aspect ratio on the in-plane/out-of-plane interaction for masonry infills in RC frames. Eng Struct 189:523–540. https://doi.org/10.1016/j.engstruct.2019.03.111

Decanini LD, Liberatore L, Mollaioli F, De Sortis A (2005) Estimation of near-source ground motion and seismic behaviour of RC framed structures damaged by the 1999 Athens earthquake. J Earthq Eng 9(5):609–635. https://doi.org/10.1080/13632460509350559

Decanini LD, Liberatore L, Mollaioli F (2012) Damage potential of the 2009 L’Aquila, Italy, earthquake. J Earthq Tsunami 6(3):1250032. https://doi.org/10.1142/S1793431112500327

Di Domenico M, Ricci P, Verderame GM (2021) Empirical assessment of the out-of-plane strength of unreinforced masonry infills with openings under earthquake loading. Can J Civ Eng 48(9):1231–1234. https://doi.org/10.1139/cjce-2020-0463

Di Trapani F, Macaluso G, Cavaleri L, Papia M (2015) Masonry infills and RC frames interaction: literature overview and state of the art of macromodeling approach. Eur J Environ Civ Eng 19(9):1059–1095. https://doi.org/10.1080/19648189.2014.996671

Di Trapani F, Shing PB, Cavaleri L (2018) Macroelement Model for in-plane and out-of-plane responses of masonry infills in frame structures. J Struct Eng 144(2):04017198. https://doi.org/10.1061/(ASCE)ST.1943-541X.0001926

DIN EN 1052, (1998) Teile 1, 2, 3, 5: Prüfverfahren für Mauerwerk, Deutsche Fassung EN 1052–2, Teil 1 – Dezember 1998

DIN EN 1015 (2007), Teile 3, 7, 11, Prüfverfahren für Mörtel für Mauerwerk, Deutsche Fassungen EN 772, Teil 3 – Mai 2007

DIN EN 1998–1 (2010) Eurocode 8: Auslegung von Bauwerken gegen Erdbeben – Teil 1: Grundlagen, Erdbebeneinwirkungen und Regeln für Hochbauten; Deutsche Fassung EN 1998–1:2004 + AC:2009

DIN EN 1992–1–1 (2011) Eurocode 2: Bemessung und Konstruktion von Stahlbeton- und Spann-betontrag-werken – Teil 1–1: Allgemeine Bemessungsregeln und Regeln für den Hochbau; Deutsche Fassung EN 1992–1–1:2004 + AC:2010

DIN EN 772, Teile 1–21: Prüfverfahren für Mauersteine, Deutsche Fassungen EN 772, Teil 1 – Mai 2016

El-Dakhakhni WW, Elgaaly M, Hamid AA (2003) Three-strut model for concrete masonry-infilled steel frames. J Struct Eng 129(2):177–185. https://doi.org/10.1061/(ASCE)0733-9445(2003)129:2(177)

EN 1992–1–1 (2004). Eurocode 2: Design of concrete structures -Part 1–1: General rules and rules for buildings. CEN, Brussels, Belgium

EN 1998-1 (2004) Eurocode 8: Design of structures for earthquake resistance. Part 1: General rules, seismic actions and rules for buildings (EN 1998-1). CEN, Brussels, Belgium

Fardis MN (2006) Seismic design issues for masonry-infilled RC frames. In: 1st European conference on earthquake engineering and seismology, Geneva, Switzerland

Flanagan RD, Bennett RM (1999a) In-plane behavior of structural clay tile infilled frames. J Struct Eng 125(6):590–599. https://doi.org/10.1061/(ASCE)0733-9445(1999)125:6(590)

Flanagan RD, Bennett RM (1999b) Bidirectional behavior of structural clay tile infilled frames. J Struct Eng 125(3):236–244. https://doi.org/10.1061/(ASCE)0733-9445(1999)125:3(236)

Flanagan RD, Bennett RM (1999c) Arching of masonry infilled frames: comparison of analytical methods. Pract Period Struct Des Constr 4(3):105–110. https://doi.org/10.1061/(ASCE)1084-0680(1999)4:3(105)

Flanagan RD, Bennett RM (2001) In-plane analysis of masonry infill materials. Pract Period Struct Des Constr 6(4):176–182. https://doi.org/10.1061/(ASCE)1084-0680(2001)6:4(176)

Furtado A, Rodrigues H, Arêde A, Varum H (2016) Experimental evaluation of out-of-plane capacity of masonry infill walls. Eng Struct 111:48–63. https://doi.org/10.1016/j.engstruct.2015.12.013

Furtado A, Arêde A, Rodrigues H, Varum H (2021) The role of the openings in the out-of-plane behaviour of masonry infill walls. Eng Struct 244:112793. https://doi.org/10.1016/j.engstruct.2021.112793

Griffith MC, Vaculik J (2007) Out-of-plane flexural strength of unreinforced clay brick masonry walls. TMS J 25:53–68

Hamburger, RO, Chakradeo, AS (1993) Methodology for seismic capacity evaluation of steel-frame buildings with infill unreinforced masonry. In: Mitigation and damage to the built environment, pp. 173–82

Hermanns L, Fraile A, Alarcón E, Álvarez R (2014) Performance of buildings with masonry infill walls during the 2011 Lorca earthquake. Bull Earthq Eng 12(5):1977–1997. https://doi.org/10.1007/s10518-013-9499-3

INSYSME (2016a). Innovative systems for earthquake resistant masonry in reinforced concrete buildings, http://www.insysme.eu.

Kadysiewski S, Mosalam KM (2009) Modeling of unreinforced masonry infill walls considering in-plane and out-of-plane interaction. Pacific Earthquake Engineering Research Center, PEER Report 2008/102, University of California, Berkley

Kakaletsis DJ, Karayannis CG (2008) Influence of masonry strength and openings on infilled R/C frames under cycling loading. J Earthq Eng 12(2):197–221. https://doi.org/10.1080/13632460701299138

Liauw TC, Kwan KH (1985) Unified plastic analysis for infilled frames. J Struct Eng 111(7):1427–1448. https://doi.org/10.1061/(ASCE)0733-9445(1985)111:7(1427)

Mainstone RJ (1971) On the stiffness and strengths of infilled frames. Inst Civil Eng, Proc 4:57–90

Manfredi V, Masi A (2014) Combining in-plane and out-of-plane behaviour of masonry infills in the seismic analysis of RC buildings. Earthq Struct 6(5):515–537. https://doi.org/10.12989/eas.2014.6.5.515

Manfredi G, Prota A, Verderame GM, De Luca F, Ricci P (2014) 2012 Emilia earthquake, Italy: reinforced concrete buildings response. Bull Earthq Eng 12(5):2275–2298. https://doi.org/10.1007/s10518-013-9512-x

Mansouri A, Marefat MS, Khanmohammadi M (2014) Experimental evaluation of seismic performance of low-shear strength masonry infills with openings in reinforced concrete frames with deficient seismic details. Struct Design Tall Spec Build 23(15):1190–1210. https://doi.org/10.1002/tal.1115

Marinković M, Butenweg C (2019) Innovative decoupling system for the seismic protection of masonry infill walls in reinforced concrete frames. Eng Struct 197:109435. https://doi.org/10.1016/j.engstruct.2019.109435

Marinković M, Baballëku M, Isufi B, Blagojević N, Milićević I, Brzev S (2022) Performance of RC cast-in-place buildings during the November 26, 2019 Albania earthquake. Bull Earthq Eng 20(10):5427–5480. https://doi.org/10.1007/s10518-022-01414-y

Marinković M (2018c) Innovative system for seismic resistant masonry infills in reinforced concrete frame structures. Faculty of Civil Engineering, University of Belgrade, Belgrade

McDowell EL, McKee K, Sevin E (1956a) Arching action theory of masonry walls. J Struct Div 82(2):1–8

McDowell EL, McKee KE, Sevin E (1956b) Discussion of arching action theory of masonry walls. J Struct Div 82:27–40

Mehrabi AB, Shing PB, Schuller MP, Noland JL (1996) Experimental evaluation of masonry-infilled RC frames. J Struct Eng 122(3):228–237. https://doi.org/10.1061/(ASCE)0733-9445(1996)122:3(228)

Moghaddam HA, Dowling PJ (1987) The state of the art in infilled frames (ESEE Research Report No. 87–2), Imperial College of Science and Technology. Civil Eng. Department, London, UK

Morandi P, Milanesi RR, Magenes G (2018a) Innovative solution for seismic-resistant masonry infills with sliding joints: in-plane experimental performance. Eng Struct 176:719–733. https://doi.org/10.1016/j.engstruct.2018.09.018

Morandi P, Hak S, Magenes G (2018b) Performance-based interpretation of in-plane cyclic tests on RC frames with strong masonry infills. Eng Struct 156:503–521. https://doi.org/10.1016/j.engstruct.2017.11.058

Morandi P, Hak S, Magenes G (2013) Simplified out-of-plane resistance verification for slender clay masonry infills in RC frames. In: Proceedings of the XV ANIDIS, L’Ingegneria Sismica in Italia, Padua, Italy, 30

Morandi P, Luca A, Riccardo M, Guido M (2022) Definition of performance limit states and in-plane drift capacity of URM walls according to experimental results. In: Proceedings of the 3rd European conference on earthquake engineering and seismology, Bucharest, Romania

Morandi P, Hak S, Magenes G (2017a) Experimental and numerical seismic performance of strong clay masonry infills. In Appendix: guideline proposal for seismic design of masonry infills. Research Report 2017a/02. EUCENTRE Foundation

Mosalam KM, White RN, Gergely P (1997) Static response of infilled frames using quasi-static experimentation. J Struct Eng 123(11):1462–4169. https://doi.org/10.1061/(ASCE)0733-9445(1997)123:11(1462)

Nam PH, Paolacci F, Hoang PH (2019) Seismic performance of an infilled moment-resisting steel frame during the 2016 Central Italy Earthquake. ar**v:1907.10263. https://doi.org/10.48550/ar**v.1907.10263

Ockleston AJ (1955) Load tests on a three storey reinforced concrete building in Johannesburg. Struct Eng 33:304–322

Paulay T, Priestley MJN (1992) Seismic design of reinforced concrete and masonry buildings. Wiley, New York

Perrone D, Calvi PM, Nascimbene R, Fischer EC, Magliulo G (2019) Seismic performance of non-structural elements during the 2016 Central Italy earthquake. Bull Earthq Eng 17(10):5655–5677. https://doi.org/10.1007/s10518-018-0361-5

Polyakov SV (1960) On the interaction between masonry filler walls and enclosing frame when loaded in the plane of the wall. Earthquake Engineering Research Institute, San Francisco, pp 36–42

Read JB (1965) Testing to destruction of full-size portal frames. Cement and Concrete Association

Ricci P, De Luca F, Verderame GM (2011) 6th April 2009 L’Aquila earthquake, Italy: reinforced concrete building performance. Bull Earthq Eng 9(1):285–305. https://doi.org/10.1007/s10518-010-9204-8

Ricci P, Di Domenico M, Verderame GM (2018a) Experimental assessment of the in-plane/out-of-plane interaction in unreinforced masonry infill walls. Eng Struct 173:960–978. https://doi.org/10.1016/j.engstruct.2018.07.033

Ricci P, Di Domenico M, Verderame GM (2018b) Experimental investigation of the influence of slenderness ratio and of the in-plane/out-of-plane interaction on the out-of-plane strength of URM infill walls. Constr Build Mater 191:507–522. https://doi.org/10.1016/j.conbuildmat.2018.10.011

Ricci P, Di Domenico M, Verderame GM (2018c) Empirical-based out-of-plane URM infill wall model accounting for the interaction with in-plane demand. Earthq Eng Struct Dyn 47(3):802–827. https://doi.org/10.1002/eqe.2992

Sepasdar R (2017b) Experimental investigation on the out-of-plane behaviour of concrete masonry infilled rc frames. Dalhousie University, Nova Scotia

Sigmund V, Penava D (2014) Influence of openings, with and without confinement, on cyclic response of infilled rc frames—an experimental study. J Earthq Eng 18(1):113–146. https://doi.org/10.1080/13632469.2013.817362

Smith BS (1966) Behavior of square infilled frames. J Struct Div 92(1):381–404

Stavridis A (2009) Analytical and experimental study of seismic performance of reinforced concrete frames infilled with masonry walls. University of California, San Diego

Stylianidis KC (2012) Experimental investigation of masonry infilled RC frames. Open Constr Build Technol J 6(1):194–212. https://doi.org/10.2174/1874836801206010194

Tasnimi AA, Mohebkhah A (2011) Investigation on the behavior of brick-infilled steel frames with openings, experimental and analytical approaches. Eng Struct 33(3):968–980. https://doi.org/10.1016/j.engstruct.2010.12.018

Thiruvengadam V (1985) On the natural frequencies of infilled frames. Earthq Eng Struct Dyn 13(3):401–419. https://doi.org/10.1002/eqe.4290130310

Verlato N, Guidi G, da Porto F, Modena C (2016b) Innovative systems for masonry infill walls based on the use of deformable joints: combined in-plane/out-of-plane tests. In: Proceedings of the 16th international brick and block masonry conference, Padova, Italy

Vicente RS, Rodrigues H, Varum H, Costa A, da Silva JARM (2012) Performance of masonry enclosure walls: lessons learned from recent earthquakes. Earthq Eng Eng Vib 11(1):23–34. https://doi.org/10.1007/s11803-012-0095-3

**e X, Qu Z, Fu H, Zhang L (2021) Effect of prior in-plane damage on the out-of-plane behavior of masonry infill walls. Eng Struct 226:111380. https://doi.org/10.1016/j.engstruct.2020.111380

Yuen YP, Kuang JS (2014) Masonry-infilled rc frames subjected to combined in-plane and out-of-plane loading. Int J Struct Stab Dyn 14(02):1350066. https://doi.org/10.1142/S0219455413500661

Acknowledgements

The authors gratefully acknowledge the financial support from the “Bundesverband der Deutschen Ziegelindustrie e.V. Fachgruppe Hintermauerziegel” and express their special thanks to Dr. Udo Meyer for his valuable suggestions and support during the execution of the AiF project “Development of an innovative approach for decoupling masonry infills and non-load-bearing masonry walls from the load-bearing structure”. Furthermore, we would like to thank assistant professor Matija Gams and his team from the University of Ljubljana for the execution of the experimental tests, discussions and excellent cooperation within the framework of the project.

Funding

Open Access funding enabled and organized by Projekt DEAL. This work was supported by the AiF project “Development of an innovative approach for decoupling masonry infills and non-load-bearing masonry walls from the load-bearing structure”.

Author information

Authors and Affiliations

Contributions

AM Conceptualization, Methodology, Validation, Visualization, Investigation, Data curation, Writing- Original draft preparation. MM Conceptualization, Methodology, Validation, Investigation, Supervision. CB Conceptualization, Methodology, Validation, Investigation, Writing- Reviewing and Editing, Funding acquisition, Supervision. SK Conceptualization, Methodology, Writing- Reviewing and Editing, Supervision.

Corresponding author

Ethics declarations

Conflict of Interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Milijaš, A., Marinković, M., Butenweg, C. et al. Experimental results of reinforced concrete frames with masonry infills with and without openings under combined quasi-static in-plane and out-of-plane seismic loading. Bull Earthquake Eng 21, 3537–3579 (2023). https://doi.org/10.1007/s10518-023-01664-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10518-023-01664-4