Abstract

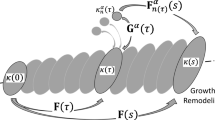

Constrained mixture models for soft tissue growth and remodeling have attracted increasing attention over the last decade. They can capture the effects of the simultaneous presence of multiple constituents that are continuously deposited and degraded at in general different rates, which is important to understand essential features of living soft tissues that cannot be captured by simple kinematic growth models. Recently the novel concept of homogenized constrained mixture models was introduced. It was shown that these models produce results which are very similar (and in certain limit cases even identical) to the ones of constrained mixture models based on multi-network theory. At the same time, the computational cost and complexity of homogenized constrained mixture models are much lower. This paper discusses the theory and implementation of homogenized constrained mixture models for anisotropic volumetric growth and remodeling in three dimensions. Previous constrained mixture models of volumetric growth in three dimensions were limited to the special case of isotropic growth. By numerical examples, comparison with experimental data and a theoretical discussion, we demonstrate that there is some evidence raising doubts whether isotropic growth models are appropriate to represent growth and remodeling of soft tissue in the vasculature. Anisotropic constrained mixture models, as introduced in this paper for the first time, may be required to avoid unphysiological results in simulations of vascular growth and remodeling.

Similar content being viewed by others

References

Albero AB, Ehret AE, Böl M (2014) A new approach to the simulation of microbial biofilms by a theory of fluid-like pressure-restricted finite growth. Comput Methods Appl Mech Eng 272:271–289

Ambrosi D, Guana F (2007) Stress-modulated growth. Math Mech Solids 12(3):319–342

Ambrosi D, Mollica F (2004) The role of stress in the growth of a multicell spheroid. J Math Biol 48(5):477–99

Ambrosi D et al (2011) Perspectives on biological growth and remodeling. J Mech Phys Solids 59(4):863–883

Baek S, Rajagopal KR, Humphrey JD (2006) A theoretical model of enlarging intracranial fusiform aneurysms. J Biomech Eng 128(1):142–9

Ben Amar M, Goriely A (2005) Growth and instability in elastic tissues. J Mech Phys Solids 53(10):2284–2319

Böl M, Bolea Albero A (2014) On a new model for inhomogeneous volume growth of elastic bodies. J Mech Behav Biomed Mater 29:582–593

Creative Commons License (2016) CC BY-SA 4.0. http://creativecommons.org/licenses/by-sa/4.0/

Cyron CJ, Humphrey JD (2014) Vascular homeostasis and the concept of mechanobiological stability. Int J Eng Sci 85:203–223

Cyron CJ, Humphrey JD (2016) Growth and remodeling of load-bearing biological soft tissues. Meccanica 1–20. doi:10.1007/s11012-016-0472-5

Cyron CJ, Wilson JS, Humphrey JD (2014) Mechanobiological stability: a new paradigm to understand the enlargement of aneurysms? J R Soc Interface 11(100):20140680

Cyron CJ, Wilson JS, Humphrey JD (2016a) Constitutive formulations for soft tissue growth and remodeling. In: Payan Y, Ohayon J (eds) Biomechanics of living organs: hyperelastic constitutive laws for finite element modeling. Elsevier, Amsterdam (forthcoming)

Cyron CJ, Aydin RC, Humphrey JD (2016b) A homogenized constrained mixture (and mechanical analog) model for growth and remodeling of soft tissue. Biomech Model Mechanobiol 15(6):1389–1403

de Souza Neto EA et al (1996) Design of simple low order finite elements for large strain analysis of nearly incompressible solids. Int J Solids Struct 33(20):3277–3296

Eriksson TSE et al (2014) Modelling volumetric growth in a thick walled fibre reinforced artery. J Mech Phys Solids 73:134–150

Etminan N et al (2014) Age of collagen in intracranial saccular aneurysms. Stroke 45(6):1757–63

Figueroa CA et al (2009) A computational framework for fluid-solid-growth modeling in cardiovascular simulations. Comput Methods Appl Mech Eng 198(45–46):3583–3602

Gee MW, Förster C, Wall WA (2010) A computational strategy for prestressing patient-specific biomechanical problems under finite deformation. Int J Numer Methods Biomed Eng 26(1):52–72

Geest JPV, Sacks MS, Vorp DA (2004) Age dependency of the biaxial biomechanical behavior of human abdominal aorta. J Biomech E 126(6):815–822

Göktepe S et al (2010) A multiscale model for eccentric and concentric cardiac growth through sarcomerogenesis. J Theor Biol 265(3):433–442

Goriely A, Vandiver R (2010) On the mechanical stability of growing arteries. IMA J Appl Math 75:549–570

Grytsan A, Watton PN, Holzapfel GA (2015) A thick-walled fluid-solid-growth model of abdominal aortic aneurysm evolution: application to a patient-specific geometry. J Biomech Eng 137(3):031008

Grytz R et al (2012) Lamina cribrosa thickening in early glaucoma predicted by a microstructure motivated growth and remodeling approach. Mech Mater 44:99–109

Holzapfel G (2000) Nonlinear solid mechanics: a continuum approach for engineering. Wiley, New York

Holzapfel G, Gasser T, Ogden R (2000) A new constitutive framework for arterial wall mechanics and a comparative study of material models. J Elast Phys Sci Solids 61(1–3):1–48

Holzapfel GA et al (2015) Modelling non-symmetric collagen fibre dispersion in arterial walls. J R Soc Interface 12(106):20150188

Humphrey JD (1999) Remodeling of a collagenous tissue at fixed lengths. J Biomech Eng 121(6):591–7

Humphrey JD, Rajagopal KR (2002) A constrained mixture model for growth and remodeling of soft tissues. Math Models Methods Appl Sci 12(03):407–430

Karšaj I, Sorić J, Humphrey JD (2010) A 3-D framework for arterial growth and remodeling in response to altered hemodynamics. Int J Eng Sci 48(11):1357–1372

Kroon M, Holzapfel GA (2007) A model for saccular cerebral aneurysm growth by collagen fibre remodelling. J Theor Biol 247(4):775–787

Kroon M, Holzapfel GA (2008) Modeling of saccular aneurysm growth in a human middle cerebral artery. J Biomech Eng 130(5):051012

Matsumoto T, Hayashi K (1996) Response of arterial wall to hypertension and residual stress. In: Hayashi K, Kamiya A, Ono K (eds) Biomechanics. Springer, Berlin, pp 93–119

Menzel A, Kuhl E (2012) Frontiers in growth and remodeling. Mech Res Commun 42:1–14

Murtada S-I, Holzapfel GA (2014) Investigating the role of smooth muscle cells in large elastic arteries: a finite element analysis. J Theor Biol 358:1–10

Murtada S-I, Kroon M, Holzapfel GA (2010a) Modeling the dispersion effects of contractile fibers in smooth muscles. J Mech Phys Solids 58(12):2065–2082

Murtada S-I, Kroon M, Holzapfel GA (2010b) A calcium-driven mechanochemical model for prediction of force generation in smooth muscle. Biomech Model Mechanobiol 9(6):749–762

Murtada SC, Arner A, Holzapfel GA (2012) Experiments and mechanochemical modeling of smooth muscle contraction: significance of filament overlap. J Theor Biol 297:176–86

Murtada S-I et al (2015) Adaptation of active tone in the mouse descending thoracic aorta under acute changes in loading. Biomech Model Mechanobiol 15(3):589–592

Nissen R, Cardinale GJ, Udenfriend S (1978) Increased turnover of arterial collagen in hypertensive rats. Proc Natl Acad Sci USA 75(1):451–453

O’Connell MK et al (2008) The three-dimensional micro-and nanostructure of the aortic medial lamellar unit measured using 3D confocal and electron microscopy imaging. Matrix Biology 27(3):171–181

Rajagopal K, Wineman A (1992) A constitutive equation for nonlinear solids which undergo deformation induced microstructural changes. Int J Plast 8(4):385–395

Rodriguez EK, Hoger A, McCulloch AD (1994) Stress-dependent finite growth in soft elastic tissues. J Biomech 27(4):455–67

Taber LA, Eggers DW (1996) Theoretical study of stress-modulated growth in the aorta. J Theor Biol 180(4):343–357

Valentin A et al (2009) Complementary vasoactivity and matrix remodelling in arterial adaptations to altered flow and pressure. J R Soc Interface 6(32):293–306

Valentín A, Humphrey J, Holzapfel GA (2013) A finite element-based constrained mixture implementation for arterial growth, remodeling, and adaptation: theory and numerical verification. Int J Numer Methods Biomed Eng 29(8):822–849

Vandiver R, Goriely A (2009) Morpho-elastodynamics: the long-time dynamics of elastic growth. J Biol Dyn 3(2–3):180–195

Virag L et al (2015) A computational model of biochemomechanical effects of intraluminal thrombus on the enlargement of abdominal aortic aneurysms. Ann Biomed Eng 43(12):2852–2867

Watton PN, Hill NA (2009) Evolving mechanical properties of a model of abdominal aortic aneurysm. Biomech Model Mechanobiol 8(1):25–42

Watton P, Hill N, Heil M (2004) A mathematical model for the growth of the abdominal aortic aneurysm. Biomech Model Mechanobiol 3(2):98–113

Watton PN et al (2011) Modelling evolution and the evolving mechanical environment of saccular cerebral aneurysms. Biomech Model Mechanobiol 10(1):109–32

Wilson JS, Baek S, Humphrey JD (2012) Importance of initial aortic properties on the evolving regional anisotropy, stiffness and wall thickness of human abdominal aortic aneurysms. J R Soc Interface 9(74):2047–58

Wilson JS, Baek S, Humphrey JD (2013) Parametric study of effects of collagen turnover on the natural history of abdominal aortic aneurysms. Proc R Soc A 469(2150):20120556

Zeinali-Davarani S, Baek S (2012) Medical image-based simulation of abdominal aortic aneurysm growth. Mech Res Commun 42:107–117

Zeinali-Davarani S, Sheidaei A, Baek S (2011) A finite element model of stress-mediated vascular adaptation: application to abdominal aortic aneurysms. Comput Methods Biomech Biomed Eng 14(9):803–817

Zöllner AM et al (2012) Stretching skeletal muscle: chronic muscle lengthening through sarcomerogenesis. PLoS ONE 7(10):e45661

Zöllner AM et al (2013) Growth on demand: reviewing the mechanobiology of stretched skin. J Mech Behav Biomed Mater 28:495–509

Acknowledgements

This work was supported by the International Graduate School for Science and Engineering (IGSSE) of the Technical University of Munich and the Emmy Noether program of the German Research Foundation DFG (CY 75/2-1). The authors thank Sebastian Fuchs for providing Fig. 1 under a Creative Commons License.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Appendices

Appendix 1

In mechanobiological equilibrium, mechanical equilibrium is satisfied and at the same time no growth and remodeling occur because the stress of each constituent subject to growth and remodeling equals the homeostatic value (Cyron and Humphrey 2014). In two-dimensional membrane models of blood vessels, it is easy to define for a given vascular geometry an initial state in mechanobiological equilibrium. The reason is that in the balance of momentum only the membrane stress rather than the Cauchy stress appears (cf. Equation (2.2) in Cyron et al. (2014)). So, one can first solve this equation to ensure mechanical equilibrium. Subsequently, one can separately vary the remaining parameters (in particular wall thickness and mass fractions) to ensure that the Cauchy stress of each constituent equals the homeostatic value.

By contrast, in three dimensions the definition of an initial state in mechanobiological equilibrium is not straightforward. In Sect. 4, we applied, inspired by Gee et al. (2010), the following procedure to initialize the simulations in mechanobiological equilibrium:

-

1.

First, the homeostatic stress (or equivalently stretch) of collagen and smooth muscle in fiber direction has to be defined. Herein, we adopt the values used already by Wilson et al. (2013) and presented in Table 1. The elastic stretches \(\lambda _\mathrm{e}^{\mathrm{co}} \left( {t=0} \right) \) and \(\lambda _\mathrm{e}^\mathrm{sm} \left( {t=0} \right) \) of collagen and smooth muscle in the initial configuration are then computed so that they correspond to these homeostatic stresses (or are equal to the chosen homeostatic stretches).

-

2.

Second, the elastic in vivo stretches of elastin in axial and circumferential direction have to be defined. Herein, we adopt the values used already by Wilson et al. (2013) and presented in Table 1. These stretches are equal to the initial stretch of elastin in axial direction \(\lambda _\mathrm{e}^{\mathrm{el}\left( {90^{\circ }} \right) } \left( {t=0} \right) \) and circumferential direction \(\lambda _\mathrm{e}^{\mathrm{el}\left( {0^{\circ }} \right) } \left( {t=0} \right) \).

-

3.

Third, the elastic stretch \(\lambda _\mathrm{e}^{\mathrm{el}\bot } \left( {t=0,r} \right) \) of elastin in wall thickness direction in the initial configuration at time \(t=0\) is computed. The stretch depends on the distance r from the cylinder axis and is computed such that the Cauchy stress \(\sigma ^{\bot }\left( r \right) \) of the whole constrained mixture in wall thickness direction linearly increases from the value \(\sigma ^{\bot }\left( {r=R} \right) =-p\) at the inner radius of the cylinder to the \(\sigma ^{\bot }\left( {r=R+H} \right) =0\) at the outer radius of the cylinder. That is, we use the condition

$$\begin{aligned} p\left( {1-\frac{r-R}{H}} \right) +\sigma ^{\bot }\left( {\lambda _\mathrm{e}^{\mathrm{el}\bot } \left( {t=0,r} \right) } \right) =0 \end{aligned}$$(40)With given strain energies from Sect. 3.3, given initial mass fractions (cf. Table 1), given initial (homeostatic) stretches of collagen and smooth muscle (cf. 1)) as well as given initial axial and circumferential stretch of elastin (cf. 2)), \(\sigma ^{\bot }\) in (40) becomes a function of only the parameter \(\lambda _\mathrm{e}^{\mathrm{el}\bot } \left( {t=0,r} \right) \), which can thus be computed from (40). Note that the only other so far unknown parameter \(\mu _\mathrm{2D}^\mathrm{el} \) does not appear in (40) because it affects only the axial and circumferential wall stress but not the radial one due to the two-dimensional elasticity of (32). Equation (40) is solved for \(\lambda _\mathrm{e}^{\mathrm{el}\bot } \left( {t=0,r} \right) \) by applying a Newton–Raphson method.

-

4.

Fourth, the material parameter \(\mu _\mathrm{2D}^\mathrm{el} \left( r \right) \) is defined such that it ensures a constant circumferential Cauchy stress of elastin despite the variation of \(\lambda _\mathrm{e}^{\mathrm{el}\bot } \left( {t=0,r} \right) \) in radial direction. This ensures mechanical equilibrium for the \(\lambda _\mathrm{e}^{\mathrm{el}\bot } \left( {t=0,r} \right) \) computed according to 3) and requires

$$\begin{aligned} \mathop \sum \limits _{i=1}^n \sigma ^{i\left( {0^{\circ }} \right) }\left( {t=0} \right) =\frac{pR}{H} \end{aligned}$$(41)with \(\sigma ^{i\left( {0^{\circ }} \right) }\left( {t=0} \right) \) the Cauchy stress of the ith constituent in circumferential direction in the initial configuration at time \(t\,{=}\,0\). Equation (41) has to hold for any \(r\in \left[ {R;R+H} \right] \), and it is solved analytically for the material parameter \(\mu _\mathrm{2D}^\mathrm{el} \left( r \right) \). Note that all parameters that are required to compute the Cauchy stresses \(\sigma ^{i\left( {0^{\circ }} \right) }\) from the strain energies defined in Sect. 3.3 are known at this point except for \(\mu _\mathrm{2D}^\mathrm{el} \). Also note that, as the elastic radial prestretch of elastin \(\lambda _\mathrm{e}^{\mathrm{el}\bot } \left( {t=0,r} \right) \) varies in wall thickness direction, also the material parameter \(\mu _\mathrm{2D}^\mathrm{el} \left( r \right) \) has to.

An initially stress-free thick-walled homogeneous cylinder on which an internal pressure is imposed exhibits in general a parabolic stress profile both of the circumferential stress \(\sigma ^{\left( {0^{\circ }} \right) }\) and radial stress \(\sigma ^{\bot }\) as illustrated in Fig. 7a. By contrast, the prestressing procedure described in this appendix leads to a configuration with constant circumferential stress \(\sigma ^{\left( {0^{\circ }} \right) }\) and linearly increasing radial stress \(\sigma ^{\bot }\) (cf. Fig. 7b) in case of uniform mass fractions and fiber orientations throughout the wall. The real stress profile over the wall thickness in arteries is currently not exactly known so that the prestressing procedure used herein should be understood as a simple way to initialize our simulations in a state of mechanobiological equilibrium rather than as a physiologically accurate procedure.

Circumferential (\({{\sigma }}^{\left( {{0}^{\circ }} \right) })\) and radial (\({{\sigma }}^{\bot })\) stress in a thick-walled cylinder from the inner radius R to the outer radius \({R+H}\) in an initially stress-free cylinder under internal pressure p (left) compared to the prestressed configuration produced by the procedure described in this appendix (right)

Appendix 2

In this appendix, we provide the first and second derivatives of the strain energy functions \(W^{\mathrm{co}}\), \(W^\mathrm{sm}\), and \(W^\mathrm{el}\) in (27), (28), and (36) with respect to the total Green–Lagrange strain \({\varvec{E}}\). For each constituent, we assume a multiplicative split of the deformation gradient into an elastic part \({\varvec{F}}_\mathrm{e}\) and an inelastic part \({\varvec{F}}_\mathrm{gr} \) (cf. (13)) and the partial derivative with respect to the total strain is computed assuming that \({\varvec{F}}_\mathrm{gr} \) is constant so that a variation of \({\varvec{E}}\) translates into a variation of \({\varvec{F}}_\mathrm{e}\) only. Note that in this appendix we omit superscripts in \({\varvec{F}}_\mathrm{gr} \) and \({\varvec{F}}_\mathrm{e}\), given that in each equation it is evident to which constituent in the constrained mixture they refer.

For collagen in (27), we have

where \({\varvec{a}}_0 \) is the unit direction vector in reference configuration of the collagen fiber family. The second derivative of the strain energy function is

The stress and elasticity of smooth muscle fiber families aligned with the unit vector \({\varvec{a}}_0\) in reference configuration are governed by

For elastin we have, according to (36), \(W^\mathrm{el}=W_\mathrm{2D}^\mathrm{el} +W_\mathrm{3D}^\mathrm{el} +W_\mathrm{vol}^\mathrm{el} \) with

where \({\varvec{C}}_\mathrm{e} \) is the elastic Cauchy–Green deformation tensor of elastin, \({\varvec{F}}_\mathrm{gr} \) its inelastic deformation gradient, \({\varvec{A}}_0^\parallel ={\varvec{F}}^{-1}{\varvec{A}}_\mathrm{gr}^\parallel {\varvec{F}}^{-\mathrm{T}}\) and the special tensor product \(\odot \) is defined such that in index notation \(\left( {{\varvec{A}} \odot {\varvec{B}}} \right) _{ijkl} =\left( {{\varvec{A}}_{ik} {\varvec{B}}_{jl} +{\varvec{A}}_{jk} {\varvec{B}}_{il} } \right) /2\). The three-dimensional neo-Hookean contribution of elastin leads to

and

with \({\varvec{C}}_\mathrm{gr} ={\varvec{F}}_\mathrm{gr}^\mathrm{T} {\varvec{F}}_\mathrm{gr} \) and the standard Cauchy–Green deformation tensor \({\varvec{C}}={\varvec{F}}^\mathrm{T}{\varvec{F}}\). The volumetric penalty term ensuring an isochoric elastic deformation of elastin leads to

and

The above equations (42), (44), (46), (48), (50), and (52) can directly be used in (9) to compute for given reference mass densities of the different constituents the second Piola–Kirchhoff stress at each point. The elasticity tensor of the constrained mixture that is required to compute the tangent stiffness matrix is, as usual, given by

where the second derivatives of the strain energies \(W^{i}\) can be computed using (43), (45), (47), (49), (51), and (53).

Appendix 3

Time integration of growth and remodeling in a finite element scheme requires updating in each time step both the inelastic deformation gradients \({\varvec{F}}_\mathrm{gr}^i \) at each Gauss point and the total displacements at each node. For our homogenized constrained mixture model, we tested two time integration schemes. In both we discretized time by a series of n discrete points in time \(t=t^{1},\ldots ,t^{n}\) with \(t^{1}=0\). The distance between two subsequent points in time was \({\Delta }t=t^{k+1}-t^{k}\). The total deformation gradient and inelastic deformation gradients at time \(t^{k}\) are \({\varvec{F}}\left( {t^{k}} \right) \) and \({\varvec{F}}_\mathrm{gr}^i \left( {t^{k}} \right) \), respectively.

In the first, explicit time integration scheme we compute at time point \(t^{k}\) from a given total deformation gradient \({\varvec{F}}\left( {t^{k}} \right) \) and inelastic deformation gradient \({\varvec{F}}_\mathrm{gr}^i \left( {t^{k}} \right) \) via the evolution equations (16)–(18) and (25) the rate \(\dot{{\varvec{F}}}_\mathrm{gr}^i\) and approximate \({\varvec{F}}_\mathrm{gr}^i \left( {t^{k+1}} \right) ={\varvec{F}}_\mathrm{gr}^i \left( {t^{k}} \right) +\dot{{\varvec{F}}}_\mathrm{gr}^i\left( {\varvec{F}}_\mathrm{gr}^i \left( {t^{k}} \right) , {\varvec{F}}\left( t^k\right) \right) \Delta t\). Then we compute from this \({\varvec{F}}_\mathrm{gr}^i \left( {t^{k+1}} \right) \), using the balance of linear momentum (4) and the equations provided in Appendix 2, iteratively the mechanical equilibrium configuration at \(t^{k+1}\), that is, \({\varvec{F}}\left( {t^{k+1}} \right) \).

In the second, implicit time integration scheme we first compute an estimate of \({\varvec{F}}_\mathrm{gr}^i \left( {t^{k+1}} \right) \) by solving (iteratively) the implicit equation \({\varvec{F}}_\mathrm{gr}^i \left( {t^{k+1}} \right) ={\varvec{F}}_\mathrm{gr}^i \left( {t^{k}} \right) +\dot{{\varvec{F}}}_\mathrm{gr}^i\left( {\varvec{F}}_\mathrm{gr}^i \left( {t^{k+1}} \right) , {\varvec{F}}\left( t^k\right) \right) \Delta t\), where \(\dot{{\varvec{F}}}_\mathrm{gr}^i\) is again computed using the evolution equations (16)–(18) and (25). Subsequently, we compute an estimate of the mechanical equilibrium configuration at time \(t^{k+1}\), that is, \({\varvec{F}}\left( {t^{k+1}} \right) \), by solving (iteratively) the balance of linear momentum (4), using the equations provided in Appendix 2. Then we compute an updated estimate of \({\varvec{F}}_\mathrm{gr}^i \left( {t^{k+1}} \right) \) based on our estimate of \({\varvec{F}}\left( {t^{k+1}} \right) \) instead of \({\varvec{F}}\left( {t^{k}} \right) \). This updated estimate of \({\varvec{F}}_\mathrm{gr}^i \left( {t^{k+1}} \right) \) is used to update also the estimate of \({\varvec{F}}\left( {t^{k+1}} \right) \), and these updates of \({\varvec{F}}_\mathrm{gr}^i \left( {t^{k+1}} \right) \) and \({\varvec{F}}\left( {t^{k+1}} \right) \) are iterated until \({\varvec{F}}\) has converged.

Both in the explicit and implicit time integration scheme, the balance of linear momentum (4) has to be solved iteratively to compute \({\varvec{F}}\left( {t^{k+1}} \right) \). To this end, Newton–Raphson iterations can be used. Note that the tangent stiffness matrix used in these iterations can be directly based on (54) in Appendix 2 in an explicit time integration scheme. In an implicit time integration scheme, however, to obtain quadratic convergence of the Newton–Raphson iterations, one has to add to the second derivatives of the strain energies in (54) an additional fourth-order tensor accounting for expected changes of the inelastic deformation gradient through the iterations of the displacement field. This additional fourth-order tensor can be computed for the ith constituent as

The computational results shown in Sect. 4 were all computed using the above-described implicit time integration scheme. Note that explicit and implicit refer in the above discussion to the update of the inelastic deformation gradient only. The balance of linear momentum is always obtained via the solution of an implicit system of equations.

Rights and permissions

About this article

Cite this article

Braeu, F.A., Seitz, A., Aydin, R.C. et al. Homogenized constrained mixture models for anisotropic volumetric growth and remodeling. Biomech Model Mechanobiol 16, 889–906 (2017). https://doi.org/10.1007/s10237-016-0859-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10237-016-0859-1