Abstract

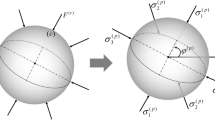

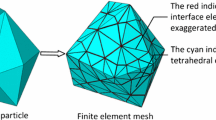

In this work, at first a new failure criterion for breakage of brittle particle systems is proposed, which combines the classical Mohr–Coulomb strength criterion with the probabilistic Weibull concept. This failure criterion is especially applicable to particle systems under compression load and accounts for the size-dependence of the material’s strength. Second, the Discrete Element Method (DEM) is implemented for sharp edged particles of convex polyhedral shape. The Mohr–Coulomb–Weibull criterion is integrated into the running DEM procedure to simulate progressive particle cracking and comminution of particle systems. The feasibility of the model was tested with simple uniaxial and triaxial compressive loading states, and the influence of relevant material parameters was studied. As a first application example of the method, an oedometric experiment was simulated, whereby coarse quartzite particles are compressed in a piston-die press. The results show good qualitative agreement with the experimentally observed particle size distribution. Thus, the ability of the suggested approach has been proved to reproduce important features as the size effect and the influence of stress state.

Similar content being viewed by others

References

Cundall, P., Strack, O.: A discrete numerical model for granular assemblies. Geotechnique 29(1), 47–65 (1979)

Weerasekara, N., Powell, M., Cleary, P., Tavares, L., Evertsson, M., Morrison, R., Quist, J., Carvalho, R.: The contribution of DEM to the science of comminution. Powder Technol. 248, 3–24 (2003). (Discrete element modelling)

Matuttis, H.-G., Chen, J.: Understanding the Discrete Element Method: Simulation of Non-spherical Particles for Granular and Multi-body Systems. Wiley, Hoboken (2014)

Lu, G., Third, J., Müller, C.: Discrete element models for non-spherical particle systems: from theoretical developments to applications. Chem. Eng. Sci. 127, 425–465 (2015)

Wang, J., Yu, H.S., Langston, P., Fraige, F.: Particle shape effects in discrete element modelling of cohesive angular particles. Granul. Matter 13(1), 1–12 (2011)

Nassauer, B., Liedke, T., Kuna, M.: Polyhedral particles for the discrete element method. Granul. Matter 15(1), 85–93 (2013)

Eliáš, J.: Simulation of railway ballast using crushable polyhedral particles. Powder Technol. 264, 458–465 (2014)

Nassauer, B., Liedke, T., Kuna, M.: Development of a coupled discrete element (DEM)–smoothed particle hydrodynamics (SPH) simulation method for polyhedral particles. Comput. Part. Mech. 3(1), 95–106 (2016)

Nassauer, B., Kuna, M.: Impact of micromechanical parameters on wire sawing: a 3D discrete element analysis. Comput. Part. Mech. 2, 63–71 (2015)

Potyondy, D., Cundall, P.: A bonded-particle model for rock. Int. J. Rock Mech. Min. Sci. 41(8), 1329–1364 (2004)

D’Addetta, A.G., Kun, F., Ramm, E.: On the application of a discrete model to the fracture process of cohesive granular materials. Granul. Matter 4(2), 77–90 (2002)

Gutierrez, A., Guichou, J.: Computational simulation of fracture of materials in comminution devices. Miner. Eng. 61, 73–81 (2014)

Laufer, I.: Grain crushing and high-pressure oedometer tests simulated with the discrete element method. Granul. Matter 17(3), 389–412 (2015)

Cleary, P., Sinnott, M.: Simulation of particle flows and breakage in crushers using DEM: Part 1—Compression crushers. Miner. Eng. 74, 178–197 (2015)

Delaney, G., Morrison, R., Sinnott, M., Cummins, S., Cleary, P.: Dem modelling of non-spherical particle breakage and flow in an industrial scale cone crusher. Miner. Eng. 74, 112–122 (2015)

Potapov, A., Campbell, C.: A three-dimensional simulation of brittle solid fracture. Int. J. Mod. Phys. C 7(5), 717–729 (1996)

Ma, G., Zhou, W., Regueiro, R., Wang, Q., Chang, X.: Modeling the fragmentation of rock grains using computed tomography and combined FDEM. Powder Technol. 308, 388–397 (2017)

De Bono, J., McDowell, G.: Particle breakage criteria in discrete-element modelling. Geotechnique 66(12), 1014–1027 (2016)

Lobo-Guerrero, S., Vallejo, L.E.: Crushing a weak granular material: experimental numerical analyses. Gotechnique 55(3), 245–249 (2005)

Kloss, C., Goniva, C., Hager, A., Amberger, S., Pirker, S.: Models, algorithms and validation for opensource DEM and CFD-DEM. Prog. Comput. Fluid Dyn. Int. J. 12(2/3), 140–152 (2012)

Šmilauer, V., et al.: Yade Documentation 2nd edn. The Yade Project (2015). http://yade-dem.org/doc/. doi:10.5281/zenodo.34073

Cundall, P.: Formulation of a three-dimensional distinct element model—Part I. A scheme to detect and represent contacts in a system composed of many polyhedral blocks. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 25(3), 107–116 (1988)

Eliáš, J.: Yade, polyhedra implementation. https://git.io/v6PD8 (2013)

Kettner, L.: 3D polyhedral surface. In: CGAL User and Reference Manual, 4.8.1 edn. CGAL Editorial Board (2016)

Guennebaud, G., Jacob, B., et al.: Eigen v3. http://eigen.tuxfamily.org (2010)

Labuz, J.F., Zang, A.: Mohr–Coulomb failure criterion. Rock Mech. Rock Eng. 45(6), 975–979 (2012)

Luding, S.: The effect of friction on wide shear bands. Part. Sci. Technol. 26(1), 33–42 (2008)

Weibull, W.: A statistical theory of the strength of materials. Ingeniörsvetenskapsakademiens handlingar, Generalstabens litografiska anstalts förlag (1939)

Weibull, W.: A statistical distribution function of wide applicability. J. Appl. Mech. 18, 293–297 (1951)

Rasche, S., Strobl, S., Kuna, M., Bermejo, R., Lube, T.: Determination of strength and fracture toughness of small ceramic discs using the small punch test and the ball-on-three-balls test. In: Procedia Materials Science, 20th European Conference on Fracture, vol. 3, pp. 961–966 (2014)

Tsoungui, O., Vallet, D., Charmet, J.-C., Roux, S.: Size effects in single grain fragmentation. Granul. Matter 2(1), 19–27 (1999)

Šmilauer, V., et al.: Dem formulation. In: Yade Documentation 2nd edn. The Yade Project (2015). http://yade-dem.org/doc/. doi:10.5281/zenodo.34044

Luding, S.: Introduction to discrete element methods. In: Darve, F., Ollivier, J.-P. (eds.) European Journal of Environmental and Civil Engineering, pp. 785–826. Lavoisier, Paris (2008)

Klichowicz, M., Reichert, M., Lieberwirth, H., Muetze, T.: Self-similarity and energy-size relationship of coarse particles comminuted in single particle mode. In: Proceedings of the XXVII International Mineral Processing Congress (2014)

Acknowledgements

The authors express their sincere appreciations to Prof. H. Lieberwirth and M. Klichowicz (Institute of Mineral Processing Machines) for the provided experimental data. This work was funded by the German Research Foundation, Project DFG KU 929/19-2.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Gladkyy, A., Kuna, M. DEM simulation of polyhedral particle cracking using a combined Mohr–Coulomb–Weibull failure criterion. Granular Matter 19, 41 (2017). https://doi.org/10.1007/s10035-017-0731-8

Received:

Published:

DOI: https://doi.org/10.1007/s10035-017-0731-8