Abstract

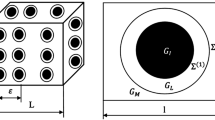

The paper focuses on deriving the macroscale viscoelastic constitutive laws using asymptotic expansion method. Both the differential and integral form of the linear viscoelastic constitutive relation of the phases is used in deriving the effective incremental potential and effective constitutive relation, respectively. The integral form is handled by considering the correspondence principle and the Laplace–Carson (LC) transform. A closed-form expression for the effective viscoelastic properties in LC domain is obtained by means of the asymptotic homogenization method (AHM). In addition, AHM coupled with finite element simulation of a representative volume element with periodic boundary conditions is used (AHM + FE). The last step in both approaches is the numerical inversion to the time domain. Solution in time domain is obtained with numerical Laplace inversion algorithms. In case of the differential form, using variational approach, the effective incremental potential in time domain is directly obtained using mean-field method. Different homogenization approaches are exemplified for evaluation of the effective relaxation behavior of composite (viscoelastic matrix reinforced by unidirectional elastic fibers), and they are compared. In the approaches based on LC transform, effective modulus and Poisson’s ratio agree well with each other for any property contrast and fiber volume fraction. However, in case of relatively low property contrast, mean field overpredicts as compared to LC approaches in the fiber direction, whereas at relatively higher property contrast, it is vice versa. The difference increases at higher volume fractions due to synergistic effect of the error due to geometrical assumptions involved in the localization tensor and interaction effects of the fiber inclusions. A good agreement in all directions is observed among the three schemes at intermediate volume fractions and property contrast. This study serves as benchmark for further theoretical improvements and experimental investigations.

Similar content being viewed by others

References

Görthofer, J., Meyer, N., Pallicity, T.D., Schöttl, L., Trauth, A., Schemmann, M., Hohberg, M., Pinter, P., Elsner, P., Henning, F., Hrymak, A., Seelig, T., Weidenmann, K., Kärger, L., Böhlke, T.: Virtual process chain of sheet molding compound: development, validation and perspectives. Compos. Part B Eng. 169, 133–147 (2019). https://doi.org/10.1016/j.compositesb.2019.04.001

Böhlke, T., Henning, F., Hrymak, A., Kärger, L., Weidenmann, K.A., Wood, J.T.: Continuous-Discontinuous Fiber-Reinforced Polymers. Carl Hanser Verlag GmbH & Co. KG, München (2019)

Moulinec, H., Suquet, P.: A numerical method for computing the overall response of nonlinear composites with complex microstructure. Comput. Methods Appl. Mech. Eng. 157, 69–94 (1998). https://doi.org/10.1016/S0045-7825(97)00218-1

Bensoussan, A., Papanicolau, G., Lions, J.-L.: Asymptotic Analysis for Periodic Structures. North-Holland (1978)

Sanchez-Palencia, E.: Non-Homogeneous Media and Vibration Theory. Springer-Verlag (1980)

Bakhvalov, N.S., Panasenko, G.: Homogenisation: Averaging Processes in Periodic Media: Mathematical Problems in the Mechanics of Composite Materials. Kluwer Academic Publishers (1989)

Eshelby, J.D.: The determination of the elastic field of an ellipsoidal inclusion and related problems. Proc. Phys. Soc. Lond. Ser. A. 241, 376–396 (1957). https://doi.org/10.1098/rspa.1983.0054

Hashin, Z.: Complex moduli of viscoelastic composites—I. General theory and application to particulate composites. Int. J. Solids Struct. 6, 539–552 (1970). https://doi.org/10.1016/0020-7683(70)90029-6

Hashin, Z.: Viscoelastic behavior of heterogeneous media. J. Appl. Mech. 32, 630 (1965). https://doi.org/10.1115/1.3627270

Christensen, R.M.: Theory of Viscoelasticity - 2nd Edition An Introduction. Academic Press, Cambridge, MA (1982)

Maghous, S., Creus, G.J.: Periodic homogenization in thermoviscoelasticity: case of multilayered media with ageing. Int. J. Solids Struct. 40, 851–870 (2003). https://doi.org/10.1016/S0020-7683(02)00549-8

Lakes, R.: Viscoelastic Materials. Cambridge University Press (2009)

Lahellec, N., Suquet, P.: On the effective behavior of nonlinear inelastic composites: I. Incremental variational principles. J. Mech. Phys. Solids 55, 1932–1963 (2007). https://doi.org/10.1016/J.JMPS.2007.02.003

Lahellec, N., Suquet, P.: On the effective behavior of nonlinear inelastic composites: II: A second-order procedure. J. Mech. Phys. Solids. 55, 1964–1992 (2007). https://doi.org/10.1016/J.JMPS.2007.02.004

Ricaud, J.-M., Masson, R.: Effective properties of linear viscoelastic heterogeneous media: Internal variables formulation and extension to ageing behaviours. Int. J. Solids Struct. 46, 1599–1606 (2009). https://doi.org/10.1016/J.IJSOLSTR.2008.12.007

Vu, Q.H., Brenner, R., Castelnau, O., Moulinec, H., Suquet, P.: A self-consistent estimate for linear viscoelastic polycrystals with internal variables inferred from the collocation method. Model. Simul. Mater. Sci. Eng. 20, 024003 (2012). https://doi.org/10.1088/0965-0393/20/2/024003

Lavergne, F., Sab, K., Sanahuja, J., Bornert, M., Toulemonde, C.: Homogenization schemes for aging linear viscoelastic matrix-inclusion composite materials with elongated inclusions. Int. J. Solids Struct. 80, 545–560 (2016). https://doi.org/10.1016/J.IJSOLSTR.2015.10.014

Miled, B., Doghri, I., Brassart, L., Delannay, L.: Micromechanical modeling of coupled viscoelastic–viscoplastic composites based on an incrementally affine formulation. Int. J. Solids Struct. 50, 1755–1769 (2013). https://doi.org/10.1016/J.IJSOLSTR.2013.02.004

Doghri, I., Adam, L., Bilger, N.: Mean-field homogenization of elasto-viscoplastic composites based on a general incrementally affine linearization method. Int. J. Plast. 26, 219–238 (2010). https://doi.org/10.1016/j.ijplas.2009.06.003

Berbenni, S., Dinzart, F., Sabar, H.: A new internal variables homogenization scheme for linear viscoelastic materials based on an exact Eshelby interaction law. Mech. Mater. 81, 110–124 (2015). https://doi.org/10.1016/J.MECHMAT.2014.11.003

Kowalczyk-Gajewska, K., Petryk, H.: Sequential linearization method for viscous/elastic heterogeneous materials. Eur. J. Mech. A/Solids. 30, 650–664 (2011). https://doi.org/10.1016/J.EUROMECHSOL.2011.04.002

Paquin, A., Sabar, H., Berveiller, M.: Integral formulation and self-consistent modelling of elastoviscoplastic behavior of heterogeneous materials. Arch. Appl. Mech. 69, 14–35 (1999). https://doi.org/10.1007/s004190050201

Sanahuja, J.: Efficient homogenization of ageing creep of random media: application to solidifying cementitious materials. In: Mechanics and Physics of Creep, Shrinkage, and Durability of Concrete. pp. 201–210. American Society of Civil Engineers, Reston, VA (2013)

Lahellec, N., Suquet, P.: Effective behavior of linear viscoelastic composites: a time-integration approach. Int. J. Solids Struct. 44, 507–529 (2007). https://doi.org/10.1016/j.ijsolstr.2006.04.038

Sabar, H., Berveiller, M., Favier, V., Berbenni, S.: A new class of micro-macro models for elastic-viscoplastic heterogeneous materials. Int. J. Solids Struct. 39, 3257–3276 (2002). https://doi.org/10.1016/S0020-7683(02)00256-1

Molinari, A.: Averaging models for heterogeneous viscoplastic and elastic viscoplastic materials. J. Eng. Mater. Technol. Trans. ASME 124, 62–70 (2002). https://doi.org/10.1115/1.1421052

Pallicity, T.D., Böhlke, T.: Effective viscoelastic behavior of polymer composites with regular periodic microstructures. Int. J. Solids Struct. 216, 167–181 (2021). https://doi.org/10.1016/j.ijsolstr.2021.01.016

Adolfsson, K., Enelund, M., Olsson, P.: On the fractional order model of viscoelasticity. Mech. Time Depend. Mater. 9, 15–34 (2005)

Bažant, Z.P., Huet, C.: Thermodynamic functions for ageing viscoelasticity: integral form without internal variables. Int. J. Solids Struct. 36, 3993–4016 (1999). https://doi.org/10.1016/S0020-7683(98)00184-X

Chatzigeorgiou, G., Charalambakis, N., Chemisky, Y., Meraghni, F.: Periodic homogenization for fully coupled thermomechanical modeling of dissipative generalized standard materials. Int. J. Plast. 81, 18–39 (2016). https://doi.org/10.1016/j.ijplas.2016.01.013

Castañeda, P.P.: New variational principles in plasticity and their application to composite materials. J. Mech. Phys. Solids. 40, 1757–1788 (1992). https://doi.org/10.1016/0022-5096(92)90050-C

Castañeda, P.P., Willis, J.R.: Variational second-order estimates for nonlinear composites. Proc. R. Soc. London Ser. A Math. Phys. Eng. Sci. 455, 1799–1811 (1999). https://doi.org/10.1098/rspa.1999.0380

Ponte Castañeda, P.: Second-order homogenization estimates for nonlinear composites incorporating field fluctuations: I—theory. J. Mech. Phys. Solids 50, 737–757 (2002). https://doi.org/10.1016/S0022-5096(01)00099-0

Huang, Y., Abou-Chakra Guéry, A., Shao, J.-F.: Incremental variational approach for time dependent deformation in clayey rock. Int. J. Plast. 64, 88–103 (2015). https://doi.org/10.1016/J.IJPLAS.2014.07.003

Guinovart-Díaz, R., Bravo-Castillero, J., Rodríguez-Ramos, R., Sabina, F.J.: Closed-form expressions for the effective coefficients of fibre-reinforced composite with transversely isotropic constituents. I: elastic and hexagonal symmetry. J. Mech. Phys. Solids 49, 1445–1462 (2001). https://doi.org/10.1016/S0022-5096(01)00005-9

Rodríguez-Ramos, R., Sabina, F.J., Guinovart-Díaz, R., Bravo-Castillero, J.: Closed-form expressions for the effective coefficients of a fiber-reinforced composite with transversely isotropic constituents - I Elastic and square symmetry. Mech. Mater. 33, 223–235 (2001). https://doi.org/10.1016/S0167-6636(00)00059-4

Bravo-Castillero, J., Guinovart-Díaz, R., Rodríguez-Ramos, R., Sabina, F.J., Brenner, R.: Unified analytical formulae for the effective properties of periodic fibrous composites. Mater. Lett. 73, 68–71 (2012). https://doi.org/10.1016/j.matlet.2011.12.106

Otero, J.A., Rodríguez-Ramos, R., Guinovart-Díaz, R., Cruz-González, O.L., Sabina, F.J., Berger, H., Böhlke, T.: Asymptotic and numerical homogenization methods applied to fibrous viscoelastic composites using Prony’s series. Acta Mech. 231, 2761–2771 (2020). https://doi.org/10.1007/s00707-020-02671-1

Rodríguez-Ramos, R., Otero, J.A., Cruz-González, O.L., Guinovart-Díaz, R., Bravo-Castillero, J., Sabina, F.J., Padilla, P., Lebon, F., Sevostianov, I.: Computation of the relaxation effective moduli for fibrous viscoelastic composites using the asymptotic homogenization method. Int. J. Solids Struct. 190, 281–290 (2020). https://doi.org/10.1016/j.ijsolstr.2019.11.014

Cruz-González, O.L., Rodríguez-Ramos, R., Otero, J.A., Ramírez-Torres, A., Penta, R., Lebon, F.: On the effective behavior of viscoelastic composites in three dimensions. Int. J. Eng. Sci. (2020). https://doi.org/10.1016/j.ijengsci.2020.103377

Cruz-González, O.L., Ramírez-Torres, A., Rodríguez-Ramos, R., Otero, J.A., Penta, R., Lebon, F.: Effective behavior of long and short fiber-reinforced viscoelastic composites. Appl. Eng. Sci. (2021). https://doi.org/10.1016/j.apples.2021.100037

Penta, R., Gerisch, A.: Investigation of the potential of asymptotic homogenization for elastic composites via a three-dimensional computational study. Comput. Vis. Sci. 17, 185–201 (2015). https://doi.org/10.1007/s00791-015-0257-8

Penta, R., Gerisch, A.: The asymptotic homogenization elasticity tensor properties for composites with material discontinuities. Contin. Mech. Thermodyn. 29, 187–206 (2017). https://doi.org/10.1007/s00161-016-0526-x

Valsa, J., Brančik, L.: Approximate formulae for numerical inversion of Laplace transforms. Int. J. Numer. Model Electron. Netw. Devices Fields 11, 153–166 (1998)

Juraj: Numerical Inversion of Laplace Transforms in Matlab - File Exchange - MATLAB Central, https://www.mathworks.com/matlabcentral/fileexchange/32824-numerical-inversion-of-laplace-transforms-in-matlab

Penta, R., Gerisch, A.: An introduction to asymptotic homogenization. Lect. Notes Comput. Sci. Eng. 122, 1–26 (2017). https://doi.org/10.1007/978-3-319-73371-5_1

Kehrer, L.M.: Thermomechanical mean-field modeling and experimental characterization of long fiber-reinforced sheet molding compound composites. (2019)

Trauth, A., Bondy, M., Weidenmann, K.A., Altenhof, W.: Mechanical properties and damage evolution of a structural sheet molding compound based on a novel two step curing resin system. Mater. Des. 143, 224–237 (2018). https://doi.org/10.1016/J.MATDES.2018.02.002

Böhlke, T., Brüggemann, C.: Graphical representation of the generalized Hooke’s Law. Tech. Mech. 21, 145–158 (2001)

Kehrer, L., Wood, J.T., Böhlke, T.: Mean-field homogenization of thermoelastic material properties of a long fiber-reinforced thermoset and experimental investigation. J. Compos. Mater. (2020). https://doi.org/10.1177/0021998320920695

Ye, B.S., Svenson, A.L., Bank, L.C.: Mass and volume fraction properties of pultruded glass fibre-reinforced composites. Composites 26, 725–731 (1995). https://doi.org/10.1016/0010-4361(95)91140-Z

Ghossein, E., Lévesque, M.: Homogenization models for predicting local field statistics in ellipsoidal particles reinforced composites: comparisons and validations. Int. J. Solids Struct. 58, 91–105 (2015). https://doi.org/10.1016/j.ijsolstr.2014.12.021

Böhm, H.J.: A short introduction to basic aspects of continuum micromechanics - ILSB Report / ILSB-Arbeitsbericht 206. (2021)

Hashin, Z., Shtrikman, S.: A variational approach to the theory of the elastic behaviour of polycrystals. J. Mech. Phys. Solids 10, 343–352 (1962). https://doi.org/10.1016/0022-5096(62)90005-4

Walpole, L.J.: On the overall elastic moduli of composite materials. J. Mech. Phys. Solids 17, 235–251 (1969). https://doi.org/10.1016/0022-5096(69)90014-3

Acknowledgements

TDP gratefully acknowledges German Research Foundation (DFG) within the International Research Training Group “Integrated engineering of continuous–discontinuous long fiber-reinforced polymer structures” (GRK 2078—2). OLCG kindly thank to Ecole Doctorale no. 353 de L’Universitéde Aix Marseille and L’équipe Matériaux & Structures du Laboratoire de Mécanique et d’Acoustique LMA—UMR 7031 AMU—CNRS—Centrale Marseille 4 impasse Nikola Tesla CS 40 0 06 13453 Marseille Cedex 13, France. RR acknowledges partial financial support by the German Research Foundation (DFG) within the International Research Training. Group “Integrated engineering of continuous/discontinuous long fiber-reinforced polymer structures” (GRK 2078) for inviting him as a guest scientist and the funding of PREI-DGAPA-UNAM, Mexico, which allowed to prepare the manuscript.

Author information

Authors and Affiliations

Contributions

TDP drafted, reviewed and edited the manuscript, performed investigations, implemented the IVMFH scheme, gathered all the individual contributions and combined them to the manuscript. OLCG implemented and drafted section on AHM + FE, performed investigations and reviewed and edited the manuscript. JAO supervised the work, drafted and implemented section on AHM and reviewed and edited the manuscript. RRR supervised, reviewed and edited the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix

Implementation of IVMFH approach

Figure

11 shows the flowchart of the incremental approach to compute the effective response of the composite as described in Sect. 4.2. The core aspect of the algorithm lies in finding the unknown pair of quantities \(\left( {\theta^{{\gamma_{\alpha } }} ,\,\;{\varvec{\varepsilon}}_{{\text{ov n}}}^{{\gamma_{\alpha } }} } \right)\) for all N—Maxwell branches using Eq. (24). These are assembled in a column vector X for γ-phase. This vector of unknowns is given as an input to a function specified in the form F(X) = 0 (Fig. 11), which is given as

The function is assembled with the pair of unknowns for all N-Maxwell branches using expanded form of Eq. (24). The flowchart also indicates the dependencies of the quantities involved in the computations. The steps for determining the effective response of the composite are summarized as follows:

The first and second moments of the internal strain (\(\left\langle {\varvec{\varepsilon}^{\prime}}_{{\text{v}}} \right\rangle^{\gamma }\) and \(\left\langle {\varvec{\varepsilon}^{\prime}_{{\text{v}}} \cdot \varvec{\varepsilon}^{\prime}}_{{\text{v}}} \right\rangle^{\gamma }\), respectively) at past time tn are known for γ-phase. Here, the initial conditions are assumed that \(\left\langle {\varvec{\varepsilon}^{\prime}}_{{\text{v}}} \right\rangle^{\gamma } = \it {\varvec{0}}\) and \(\left\langle {\varvec{\varepsilon}^{\prime}_{{\text{v}}} \cdot \varvec{\varepsilon}^{\prime}}_{{\text{v}}} \right\rangle^{\gamma } = 0\).

The nonlinear set of equations involved in F(X) is solved for all Maxwell branches. The unknown vector X at t is initialized at ith iteration to the solution vector Xn available at tn to achieve a faster convergence. However, at t = 0 it is assumed that the shear viscosity in the actual problem and virtual thermoelastic problem is same, and the effective internal variable in the virtual problem is zero. Hence, the pair of unknowns for α-Maxwell element in γ-phase is initialized as \(\theta^{{\gamma_{\alpha } }} = 1,\,\;{\varvec{\varepsilon}}_{{{\text{ov }}n}}^{{\gamma_{\alpha } }} = \it \varvec{0}\). Based on this, all the thermoelastic constants for the virtual thermoelastic problem are evaluated using Eq. (27) before entering a Jacobian-free optimization loop:

The first and second moments of the total strain (\(\left\langle {\varvec{\varepsilon}} \right\rangle^{\gamma }\) and \(\left\langle {{\varvec{\varepsilon}^{\prime}} \cdot {\varvec{\varepsilon}^{\prime}}} \right\rangle^{\gamma } ,\) respectively) in the virtual thermoelastic problem are evaluated using an appropriate elastic MFH scheme such as HSLB or DI method for the considered composite microstructure. These moments depend on the thermoelastic constants which in turn depend on unknown vector X.

Based on step 2.1, the first and second moment of the internal strain for the α-Maxwell element in γ-phase (\(\left\langle {\varvec{\varepsilon}^{\prime}_{{\text{v}}} } \right\rangle^{{\gamma_{\alpha } }}\) and \(\left\langle {\varvec{\varepsilon}^{\prime}_{{\text{v}}} \cdot \varvec{\varepsilon}^{\prime}}_{{\text{v}}} \right\rangle^{{\gamma_{\alpha } }}\), respectively) is evaluated using local field solution in Eq. (25). These quantities also depend on unknown vector X via \(\left\langle {\varvec{\varepsilon}} \right\rangle^{\gamma }\) and \(\left\langle {\varvec{\varepsilon}^{\prime} \cdot \varvec{\varepsilon}^{\prime}} \right\rangle^{\gamma }\).

The residual for F(X) is computed. If the residual vector is approximately zero, store the first and second moments of the internal strain and go to step 3, else return to step 2.1. The Jacobian of the F(X) is approximated numerically using finite difference.

The macroscopic stress Σ at t can be obtained by the using the converged solution vector X obtained at i + 1 iteration of the optimization loop via Eqs. (25) and (29) (Fig. 11). If t ≤ T, return to step 1 else the time loop stops.

This scheme is implemented in MATLAB using trust-region-dogleg algorithm available in fsolve function. All the tensor calculations are done in the normalized Voigt notation.

Evaluation of first and second moments of total strain

The first and second moment of the internal strain deviator as required in Eq. (24)1 depends on the first and second moment of the total strain by use of Eq. (25). These are expressed [52] as

where δGγ is variation in the shear modulus, \({\mathbb{A}}^{\gamma }\) is the strain localization tensor and aγ is the thermal strain localization tensor of γ-phase. It is sufficient to define \({\mathbb{A}}^{\gamma }\) for homogenizing a two-phase thermoelastic composite problem (see Eq. (A.5)).

Mean-field solution of a linear thermoelastic homogenization problem

Consider a two-phase linear thermoelastic composite (identified as phase γ = 1 and 2, labeled as “m” and “f,” respectively) defined with the thermoelastic energy function of the local constituents as

where the local terms εθ is the thermal strain and β is the thermal stress. Consider the composite constitutes of fiber stiffness surrounded by the matrix stiffness, i.e., \({\mathbb{C}}^{{\text{f}}}\) and \({\mathbb{C}}^{{\text{m}}}\), respectively, with the thermal stresses βf and βm. The effective thermoelastic energy function and effective stress are given as

where B is the effective thermal stress, \(\delta {\mathbb{C}} = {\mathbb{C}}^{{\text{f}}} - {\mathbb{C}}^{{\text{m}}}\), δβ = βf–βm and \({\mathbb{A}}^{{\text{f}}}\) is the strain localization tensor for the fiber phase. In two-phase composite problem, the following two identities are applicable, i.e., \(\left\langle {\mathbb{A}} \right\rangle = {\mathbb{I}}^{{\text{s}}}\) and \(\left\langle {\varvec{a}} \right\rangle = \it {\varvec{0}}\). In this problem, it is sufficient to define \({\mathbb{A}}^{{\text{f}}}\) as the thermal strain localization tensor af can be expressed in terms of \({\mathbb{A}}^{{\text{f}}}\) [53] as

The strain localization tensor for the fiber phase \({\mathbb{A}}^{\text{f}}\) is defined by HSLB elastic homogenization scheme.

4.1 Hashin–Shtrikman lower bound (HSLB)

A closer estimate of effective elastic stiffness tensor can be obtained using a variational principle [54] that yields in estimating the upper and lower bounds of the effective stiffness of composite by the choice of reference medium. If the comparison material corresponds to the matrix material or the compliant medium, it estimates the lower bound of the effective stiffness. The strain localization tensor corresponding to the lower bound is given as

where the strain localization tensor \({\mathbb{A}}^{{{\text{SIP}}}}\) corresponds to a single inclusion problem and \(\delta {\mathbb{C}} = {\mathbb{C}}^{\text{f}} - {\mathbb{C}}_{{\text{o}}}\) with \({\mathbb{C}}_{{\text{o}}} = {\mathbb{C}}^{{\text{m}}}\) for HSLB. The Hill’s polarization tensor, \({\mathbb{P}}_{{\text{o}}}\), is a function of the elastic properties of the comparison material, i.e., the matrix material in case of HSLB and the geometrical shape of the inhomogeneity [55]. In case of UD FRP composites, the geometrical shape of the fiber is modeled as a needle-shaped inclusion rather than actually being a cylinder of higher aspect ratio [50].

Rights and permissions

About this article

Cite this article

Pallicity, T.D., Cruz-González, O.L., Otero, J.A. et al. Effective behavior of viscoelastic composites: comparison of Laplace–Carson and time-domain mean-field approach. Arch Appl Mech 92, 2371–2395 (2022). https://doi.org/10.1007/s00419-022-02181-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-022-02181-7