Abstract

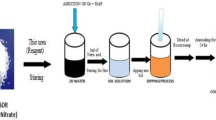

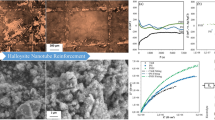

Titanium and its alloys are substantially used as prosthetics, for internal screw fixation in the human body, due to their incredible chemical and mechanical properties. But, due to the low hardness and high coefficient of friction of titanium alloys, which led to poor wear properties. Hence, in the present work, nano-alumina/hydroxyapatite/graphene as the bioactive coating are deposited using the sol–gel method on the Ti–6Al–4V alloy to improve its biomechanical properties. After coating, the tribological behavior, antibacterial activity, and apatite nuclei in simulated body fluid were evaluated. The resultant coatings surface morphology and worn substrates were studied by scanning electron microscopy. The presence of alumina/hydroxyapatite/graphene was evidenced by energy dispersive X-ray peaks. The topography of the coated surface was inspected, using the atomic force microscope. The coatings on the Ti–6Al–4V alloy resulted in enhanced surface roughness for cell attachment and cell growth. The hardness of the coated and uncoated substrates was investigated by Vickers microhardness tester. The microhardness test reveals that coating substrates exhibits 72% hardness as compared to uncoated substrates. The tribological test was conducted by a pin-on-disc testing machine by varying the process parameters like load, velocity, and distance. The results show that the Ti–6Al–4V alloy with coating exhibited greater wear resistance as compared to the uncoated Ti–6Al–4V alloy. The biomimetic apatite was found on the coated surface after a period from 1 to 7 days when immersed in SBF at 37 °C, signifying an enhancement in apatite nucleation. Ti–6Al–4V alloy with nano-alumina/hydroxyapatite/graphene coating can be proved as a potential applicant for significant antibacterial activity in load-bearing performance in bio-implants.

Similar content being viewed by others

References

A. Al-Mobarak, A. Al-Swayih, Development of titanium surgery implants for improving osseointegration through formation of a titanium nanotube layer. Int. J. Electrochem. Sci. 9, 32–45 (2014)

S.R. Fardi, H. Khorsand, R. Askarnia, R. Pardehkhorram, E. Adabifiroozjaei, Improvement of biomedical functionality of titanium by ultrasound-assisted electrophoretic deposition of hydroxyapatite-graphene oxide nanocomposites. Ceram. Int. 46, 18297–18307 (2020)

L. Benea, E. Mardare-Danaila, M. Mardare, J.P. Celis, Preparation of titanium oxide and hydroxyapatite on Ti-6Al-4V alloy surface and electrochemical behaviour in bio-simulated fluid solution. Corros. Sci. 80, 331–338 (2014)

J. Lario, M. Viera, Á. Vicente, A. Igual, V. Amigó, Corrosion behaviour of Ti6Al4V ELI nanotubes for biomedical applications. J. Market. Res. 8(6), 5548–5556 (2019)

V.S. Kattimani, S. Kondaka, K.P. Lingamaneni, Hydroxyapatite—past, present, and future in bone regeneration. Bone Tissue Regen. Insights 7, 9–19 (2016)

C. Domínguez-Trujillo, E. Peón, E. Chicardi, H. Pérez, J.A. Rodríguez-Ortiz, J.J. Pavón et al., Sol-gel deposition of hydroxyapatite coatings on porous titanium for biomedical applications. Surf. Coat. Technol. 333, 158–162 (2018)

V. Sivamaran, V. Balasubramanian, M. Gopalakrishnan, V. Viswabaskaran, A. Gourav Rao, Optimizing chemical vapor deposition parameters to attain minimum diameter carbon nano tubes by response surface methodology. J. Adv. Microsc. Res. 13, 181–189 (2018). https://doi.org/10.1166/jamr.2018.1377

V. Sivamaran, V. Balasubramanian, M. Gopalakrishnan, V. Viswabaskaran, A. Gourav Rao, Develo** empirical relationship to predict the diameter of multiwall carbon nano tubes (MWCNTs) synthesized by chemical vapor deposition (Cvd) process. Manuf. Technol. Today 16, 6 (2017)

V. Sivamaran, V. Balasubramanian, M. Gopalakrishnan, V. Viswabaskaran, A. Gourav Rao, Mechanical and tribological properties of self-lubricating Al 6061 hybrid nano metal matrix composites reinforced By NSiC and MWCNTs. Surf. Interfaces (2020). https://doi.org/10.1016/j.surfin.2020.100781

A.K. Kasar, P.L. Menezes, Synthesis and recent advances in tribological applications of graphene. Int. J. Adv. Manuf. Technol. 97(9–12), 3999–4019 (2018)

G. Wei, C. Gong, K. Hu, Y. Wang, Y. Zhang, Biomimetic hydroxyapatite on graphene supports for biomedical applications: a review. Nanomaterials 9, 1–20 (2019)

G. Shen, F. Fang, C. Kang, Nanotechnology and precision engineering tribological performance of bioimplants: a comprehensive review. Nanotechnol. Precis. Eng. 1(2), 107–122 (2018)

M. Vallet-Regí, A.J. Salinas, in Ceramics As Bone Repair Materials, 2nd edn, vol. 63. Bone Repair Biomaterials (Woodhead Publishing Limited, 2019), pp 194–230

C.W. Kang, F.Z. Fang, State of the art of bioimplants manufacturing: part II. Adv. Manuf. 6(2), 137–154 (2018)

S. Priyadarsini, S. Mohanty, S. Mukherjee, S. Basu, M. Mishra, Graphene and graphene oxide as nanomaterials for medicine and biology application. J. Nanostruct. Chem. 8(2), 123–137 (2018)

D. Sidane, D. Chicot, S. Yalaa, S. Ziania, H. Khireddine, A. Iost, X. Decoopman, Study of the mechanical behavior and corrosion resistance of hydroxyapatite sol–gel thin coatings on 316 L stainless steel pre-coated with titania film. Thin Solid Films 593, 71–80 (2015)

D. Sidane, H. Khireddine, F. Bir, S. Yala, A. Montagne, D. Chicot, Hydroxyapatite-TiO2-SiO2-coated 316L stainless steel for biomedical application. Metall. Mater. Trans. A. 48, 3570–3582 (2017)

M. Catauro, F. Bollino, R. Giovanardi, P. Veronesi, Modification of Ti6Al4V implant surfaces by biocompatible TiO2/PCL hybrid layers prepared via sol-gel dip coating: structural characterization, mechanical and corrosion behavior. Mater. Sci. Eng., C 74, 501–507 (2017)

W.S.W. Harun, R.I.M. Asri, J. Alias, F.H. Zulkifli, K. Kadirgama, S.A.C. Ghani, J.H.M. Shariffuddin, A comprehensive review of hydroxyapatite-based coatings adhesion on metallic biomaterials. Ceram. Int. 44(2), 1250–1268 (2018)

A. Gómez-Gómez, A. Nistal, E. García, M.I. Osendi, M. Belmonte, P. Miranzo, The decisive role played by graphene nanoplatelets on improving the tribological performance of Y2O3-Al2O3-SiO2 glass coatings. Mater. Des. 112, 449–455 (2016)

J. Ren, D. Zhao, F. Qi, W. Liu, Y. Chen, Heat and hydrothermal treatments on the microstructure evolution and mechanical properties of plasma sprayed hydroxyapatite coatings reinforced with graphene nanoplatelets. J. Mech. Behav. Biomed. Mater. 101, 1–9 (2020)

C. Janković, A. Eraković, S. Mitrić, V. Mišković-stanković, Bioactive hydroxyapatite/graphene composite coating and its corrosion stability in simulated body fluid Vin č a institute of nuclear sciences. J. Alloy. Compd. 624, 148–157 (2014)

K.A. El-Aziz, D. Saber, H.E.D.M. Sallam, Wear and corrosion behavior of Al–Si matrix composite reinforced with alumina. J. Bio- Tribo-Corros. I(1), 1–10 (2015)

S. Sarbishei, M.A. FaghihiSani, M.R. Mohammadi, Study plasma electrolytic oxidation process and characterization of coatings formed in an alumina nanoparticle suspension. Vacuum 108, 12–19 (2014)

P.C. Wong, S.M. Song, P.H. Tsai, Y.Y. Nien, J.S.C. Jang, C.K. Cheng, C.H. Chen, Relationship between the surface roughness of biodegradable mg-based bulk metallic glass and the osteogenetic ability of mg63 osteoblast-like cells. Materials 13(5), 1188 (2020)

J.C.M. Souza, S.L. Barbosa, E.A. Ariza, M. Henriques, W. Teughels, P. Ponthiaux et al., How do titanium and Ti6Al4V corrode in fluoridated medium as found in the oral cavity? An in vitro study. Mater. Sci. Eng., C 47, 384–393 (2015)

D. Sidane, H. Khireddine, S. Yala, The hardness of the hydroxyapatite-titania bilayer coatings by microindentation and nanoindentation testing. IOP Conf Ser.: J. Phys.: Conf. Ser. 939, 012027 (2017)

X. Gao, M. Fraulob, G. Haïat, Biomechanical behaviour of bone-implant interface: a review biomechanical behaviours of the bone- implant interface: a review. J. R. Soc. Interface (2019). https://doi.org/10.1098/rsif.2019.0259

A.M. Sadoun, A. Fathy, Experimental study on tribological properties of Cu–Al2O3 nanocomposite hybridized by graphene nanoplatelets. Ceram. Int. 45(18), 24784–24792 (2019)

R. Palanivelu, A.R. Kumar, Scratch and wear behaviour of plasma sprayed nano ceramics bilayer Al 2 O 3–13 wt%TiO 2 /hydroxyapatite coated on medical grade titanium substrates in SBF environment. Appl. Surf. Sci. 315(1), 372–379 (2014)

W. Cui, G. Qin, J. Duan, H. Wang, A graded nano-TiN coating on biomedical Ti alloy: low friction coefficient, good bonding and biocompatibility. Mater. Sci. Eng., C 71, 520–528 (2017)

A.F. Yetim, A. Alsaran, A. Celik, I. Efeoglu, Corrosion behaviour of Ti DLC deposition on prenitrided 316L stainless steel and Ti-6Al-4V alloy. Corros. Eng., Sci. Technol. 46(4), 439–444 (2011)

N. Radhika, Analysis of tribological behaviour of functionally graded LM13 aluminium/TiS2composite using design of experiments. Tribol. Ind. 38(3), 425–434 (2016)

J.C.M. Souza, H.A. Tajiri, C.S. Morsch, M. Buciumeanu, M.T. Mathew, F.S. Silva, B. Henriques, Tribocorrosion behavior of Ti6Al4V coated with a bio-absorbable polymer for biomedical applications. J. Bio- Tribo-Corros. 1(4), 2–7 (2015)

M.A. Kumar, The effect of lubrication on tribological properties of bearing materials using pin on disc: a review. Int. J. Res. Appl. Sci. Eng. Technol. 8, 267–276 (2017)

G. Rasool, S. Mridha, M.M. Stack, Map** wear mechanisms of TiC/Ti composite coatings. Wear 329, 498–508 (2015)

C. Taltavull, B. Torres, A.J. López, J. Rams, Dry sliding wear behavior of AM60B magnesium alloy. Wear 301(1–2), 615–625 (2013)

G. Straffelini, Wear mechanisms. Springer Tracts Mech. Eng. 11, 85–113 (2015)

K. Yang, J. Rong, C. Liu, H. Zhao, S. Tao, C. Ding, Study on erosion-wear behavior and mechanism of plasma-sprayed alumina-based coatings by a novel slurry injection method. Tribol. Int. 93, 29–35 (2016)

V. Kumar, A.K. Mishra, B.K. Roy, Application of Taguchi technique to optimize tribological behaviour of Al6061T6/SiC/Al2O3 metal matrix composite element Si. Int. J. Scient. Res. Publ. 4, 359–366 (2012)

L. Li, J. Feng, C. Liang, J. An, Dry sliding wear behavior and mild-severe wear transition of Mg97Zn1Y2 alloy at elevated temperatures. Materials 11(9), 1–19 (2018)

U. Elaiyarasan, V. Satheeshkumar, C. Senthilkumar, A study on wear behaviour of electrical discharge-coated magnesium alloy. J. Bio- Tribo-Corros. 5(1), 1–9 (2019)

N. Vashishtha, S.G. Sapate, Abrasive wear maps for High Velocity Oxy Fuel (HVOF) sprayed WC-12Co and Cr3C2−25NiCr coatings. Tribol. Int. 114(February), 290–305 (2017)

G. Rasool, M.M. Stack, Wear maps for TiC composite based coatings deposited on 303 stainless steel. Tribol. Int. 74, 93–102 (2014)

R.A. Al-samarai, A.K. Haftirman, Y. Al-Douri, Effect of load and sliding speed on wear and friction of aluminum–silicon casting alloy. Int. J. Sci. Res. Publ. 2(3), 3–6 (2012)

L. Mohan, C. Anandan, Wear and corrosion behavior of oxygen implanted biomedical titanium alloy Ti-13Nb-13Zr. Appl. Surf. Sci. 282, 281–290 (2013)

D. Odabas, Effects of load and speed on wear rate of abrasive wear for 2014 Al alloy. Mater. Sci. Eng. 295(1), 1–12 (2018)

C.H. Lai, Y.W. Wu, S.D. Yeh, Y.H. Lin, Y.H. Tsai, Effects of 6-hydroxyflavone on osteoblast differentiation in MC3T3-E1 cells. Evid. Based Complement. Alternat. Med. 2014, 1–11 (2014)

A.A. El Hadad, E. Peón, F.R. García-Galván, V. Barranco, J. Parra, A. Jiménez-Morales, J.C. Galván, Biocompatibility and corrosion protection behaviour of hydroxyapatite sol-gel-derived coatings on Ti6Al4V alloy. Materials 10(2), 1–25 (2017)

Y. Huang, X. Zhang, R. Zhao, H. Mao, Y. Yan, X. Pang, Antibacterial efficacy, corrosion resistance, and cytotoxicity studies of copper-substituted carbonated hydroxyapatite coating on titanium substrate. J. Mater. Sci. 50(4), 1688–1700 (2015)

N. Murugan, C. Murugan, A.K. Sundramoorthy, In vitro and in vivo characterization of mineralized hydroxyapatite/polycaprolactone-graphene oxide based bioactive multifunctional coating on Ti alloy for bone implant applications. Arab. J. Chem. 11(6), 959–969 (2018)

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that there is no any conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shanmugapriya, Sivamaran, V., Padma Rao, A. et al. Sol–gel derived Al2O3/Gr/HAP nanocomposite coatings on Ti–6Al–4V alloy for enhancing tribo-mech properties and antibacterial activity for bone implants. Appl. Phys. A 128, 635 (2022). https://doi.org/10.1007/s00339-022-05784-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-022-05784-7