Abstract

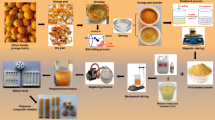

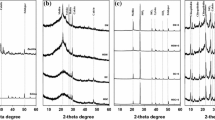

Use of agricultural waste for biocomposite is one of the main concerns of researchers because the waste is an abundant, economic, and eco-friendly source. Agro wastes of Cymbopogon flexuosus plant shoot (CFPS) from an oil extraction industry was analyzed for its feasibility as reinforcement in a metal matrix composite and as a lignocellulosic filler in a polymer matrix composite. In this study, non-carbonized and carbonized CFPS wastes were characterized by using a combination of spectroscopic and chemical techniques. The carbonized CFPS is rich in SiO2 along with other traces of hard ceramic particles as authenticated by X-ray fluorescence, X-ray diffraction, and Energy Dispersive X-Ray Spectroscopy. The presence of siloxane and silanol elemental groups was also confirmed by Fourier transform infrared spectroscopy data. Similarly, Fourier transform infrared and the X-ray diffraction spectroscopy analysis on powdered non-carbonized CFPS waste confirmed the semi-crystalline nature of the CFPS with a higher crystallinity index. Moreover, the non-carbonized CFPS had a rough surface, as confirmed by atomic force microscope and scanning electron microscope analyses. Hence, the experimental data highlighted the feasibility of the CFPS waste as filler and a substitute for silica-based inorganic fillers/reinforcement for composites in enhancing its properties.

Similar content being viewed by others

References

Binoj JS, Edwin Raj R, Daniel BSS (2018) Comprehensive characterization of industrially discarded fruit fiber, Tamarindus indica L. as a potential eco-friendly bio-reinforcement for polymer composite. J Clean Prod 116:527–534. https://doi.org/10.1016/j.jclepro.2016.09.179

Dinaharan I, Kalaiselvan K, Murugan N (2017) Influence of rice husk ash particles on microstructure and tensile behavior of AA6061 aluminum matrix composites produced using friction stir processing. Compos Commun 3:42–46. https://doi.org/10.1016/j.coco.2017.02.001

Jebadurai SG, Raj RE, Sreenivasan VS, Binoj JS (2019) Comprehensive characterization of natural cellulosic fiber from Coccinia grandis stem. Carbohydr Polym 207:675–683. https://doi.org/10.1016/j.carbpol.2018.12.027

Liu Y, Lv X, Bao J et al (2019) Characterization of silane treated and untreated natural cellulosic fibre from corn stalk waste as potential reinforcement in polymer composites. Carbohydr Polym 218:179–187. https://doi.org/10.1016/j.carbpol.2019.04.088

Yen FS, Liao HT, Wu CS (2013) Characterization and biodegradability of agricultural residue-filled polyester ecocomposites. Polym Bull 70:1613–1629. https://doi.org/10.1007/s00289-012-0862-3

Kavimani V, Gopal PM, Sumesh KR, Kumar NV (2020) Multi response optimization on machinability of SiC waste fillers reinforced polymer matrix composite using taguchi ’ s coupled grey relational analysis. Silicon. https://doi.org/10.1007/s12633-020-00782-x

Gupta A, Singh H, Walia RS (2015) Effect of fillers on tensile strength of pultruded glass fiber reinforced polymer composite. Indian J Eng Mater Sci 22:62–70

Atarian M, Reza H, Atarian M, Shokuhfar A (2012) Effect of oxide and carbide nanoparticles on tribological properties of phenolic-based nanocomposites. Iran Polym J 21:297–305. https://doi.org/10.1007/s13726-012-0038-x

Ayrilmis N, Buyuksari U (2010) Utilization of olive mill sludge in manufacture of lignocellulosic/polypropylene composite. Mater Sci 45:1336–1342. https://doi.org/10.1007/s10853-009-4087-2

Sanjay MR, Madhu P, Jawaid M et al (2018) Characterization and properties of natural fiber polymer composites: a comprehensive review. J Clean Prod 172:566–581. https://doi.org/10.1016/j.jclepro.2017.10.101

Qaiss A, Bouhfid R, Essabir H (2015) Characterization and use of coir, almond, apricot, argan, shells, and wood as reinforcement in the polymeric matrix in order to valorize these products. Springer International Publishing, pp 305–339

Masłowski M, Miedzianowska J, Strzelec K (2020) The potential application of cereal straw as a bio-filler for elastomer composites. Polym Bull 77:2021–2038. https://doi.org/10.1007/s00289-019-02848-2

Kumar R, Bhowmik S, Kumar K, Davim JP (2019) Perspective on the mechanical response of pineapple leaf filler/toughened epoxy composites under diverse constraints. Polym Bull. https://doi.org/10.1007/s00289-019-02952-3

Khalil A, Masri M, Saurabh C et al (2017) Incorporation of coconut shell based nanoparticles in kenaf/coconut fibres reinforced vinyl ester composites. Mater Res Expr 4:1–20. https://doi.org/10.1088/2053-1591/aa62ec

Santhosh MS, Karthikeyan G, Sasikumar R et al (2020) Mechanical and morphological behaviour of rice husk/prosopis juliflora reinforced bio composites. Mater Today Proc 27:556–560. https://doi.org/10.1016/j.matpr.2019.12.021

Orue A, Eceiza A, Arbelaiz A (2020) The use of alkali treated walnut shells as filler in plasticized poly (lactic acid) matrix composites. Ind Crop Prod 145:1–9. https://doi.org/10.1016/j.indcrop.2019.111993

Andrzejewski J, Szostak M, Barczewski M, Patrycja Ł (2019) Cork-wood hybrid filler system for polypropylene and poly (lactic acid) based injection molded composites. Structure evaluation and mechanical performance. Compos Part B 163:655–668. https://doi.org/10.1016/j.compositesb.2018.12.109

Kocaman S, Ahmetli G (2020) Effects of various methods of chemical modification of lignocellulose hazelnut shell waste on a newly synthesized bio: based epoxy composite. J Polym Environ 28:1190–1203. https://doi.org/10.1007/s10924-020-01675-1

Baek B, Park J, Lee B, Kim H (2013) Development and application of green composites: using coffee ground and bamboo flour. J Polym Environ 21:702–709. https://doi.org/10.1007/s10924-013-0581-3

Nourbakhsh A, Hosseinzadeh A (2011) Effects of filler content and compatibilizing agents on mechanical behavior of the particle-reinforced composites. J Polym Environ 19:908–911. https://doi.org/10.1007/s10924-011-0349-6

Prabhakar MN, Shah AUR, Rao KC, Song JI (2015) Mechanical and thermal properties of epoxy composites reinforced with waste peanut shell powder as a bio-filler. Fibers Polym 16:1119–1124. https://doi.org/10.1007/s12221-015-1119-1

Vinod A, Vijay R, Singaravelu DL (2017) ThermoMechanical characterization of calotropis gigantea stem powder-filled jute fiber-reinforced epoxy composites. J Nat Fibers 15:648–657. https://doi.org/10.1080/15440478.2017.1354740

Homkhiew C, Boonchouytan W, Cheewawuttipong W, Ratanawilai T (2018) Potential utilization of rubberwood flour and sludge waste from natural rubber manufacturing process as reinforcement in plastic composites. J Mater Cycles Waste Manag 20:1792–1803. https://doi.org/10.1007/s10163-018-0749-y

Huang L, Mu B, Yi X et al (2016) Sustainable use of coffee husks for reinforcing polyethylene composites. J Polym Environ 26:48–58. https://doi.org/10.1007/s10924-016-0917-x

Raju GU, Kumarappa S (2012) Experimental study on mechanical and thermal properties of epoxy composites filled with agricultural residue. Polym Renew Resour 3:117–138. https://doi.org/10.1177/204124791200300303

**ong W (2018) Bagasse composites: a review of material preparation, attributes, and affecting factors. Thermoplast Compos Mater 31(8):1112–1146. https://doi.org/10.1177/0892705717734596

Chevali VS, Nerenz BA, Ulven CA, Kandare E (2015) Mechanical properties of hybrid lignocellulosic fiber-filled acrylonitrile butadiene styrene (ABS) biocomposites. Polym Plast Technol Eng 54:375–382. https://doi.org/10.1080/03602559.2014.961078

Fuqua MA, Chevali VS, Ulven CA (2013) Lignocellulosic byproducts as filler in polypropylene: comprehensive study on the effects of compatibilization and loading. Appl Polym Sci 127:862–868. https://doi.org/10.1002/app.37820

Sareena C, Purushothaman E (2012) Utilization of coconut shell powder as a novel filler in natural rubber. Reinf Plast Compos 31:533–547. https://doi.org/10.1177/0731684412439116

Sajith S, Arumugam V, Dhakal HN (2017) Comparison on mechanical properties of lignocellulosic flour epoxy composites prepared by using coconut shell, rice husk and teakwood as fillers. Polym Test 58:60–67. https://doi.org/10.1016/j.polymertesting.2016.12.015

Ramesh A, Ramu K, Ahmed M et al (2020) Influence of fly ash nano filler on the tensile and flexural properties of novel hybrid epoxy nano-composites. Mater Today Proc 27:1252–1257. https://doi.org/10.1016/j.matpr.2020.02.150

Rizal S, Fizree HM, Hossain S et al (2020) The role of silica-containing agro-industrial waste as reinforcement on physicochemical and thermal properties of polymer composites. Heliyon 6:1–9. https://doi.org/10.1016/j.heliyon.2020.e03550

Rao C (2020) Effects of matrix modification on mechanical and durability characteristics of polymer composites through variations in micro fillers, macro fillers and fibers. Constr Build Mater 235:1–8. https://doi.org/10.1016/j.conbuildmat.2019.117505

Kashyap S, Datta D (2017) Industrial lime sludge waste: HDPE composites—a study of their mechanical, thermal, and morphological properties. Thermoplast Compos Mater 31:1323–1340. https://doi.org/10.1177/0892705717738289

Venkateshwaran N, Santhanam V, Alavudeen A (2019) Feasibility study of fly ash as filler in banana fiber-reinforced hybrid composites. In: Rakesh PK, Singh I (eds) Processing of green composites. Springer, Singapore, pp 31–47

Adeosun SO, Udeme OPGEIAFA (2016) Influence of organic fillers on physicochemical and mechanical properties of unsaturated polyester composites. Arab J Sci Eng 41:4153–4159. https://doi.org/10.1007/s13369-016-2120-8

Agunsoye JO, Odumosu AK, Dada O (2019) Novel epoxy-carbonized coconut shell nanoparticles composites for car bumper application. Adv Manuf Technol 102:893–899. https://doi.org/10.1007/s00170-018-3206-0

Aigbodion VS, Hassan SB, Agunsoye JO (2012) Effect of bagasse ash reinforcement on dry sliding wear behaviour of polymer matrix composites. Mater Des 33:322–327. https://doi.org/10.1016/j.matdes.2011.07.002

Prabu A, Kumaran T, Uthayakumar M, Manikandan V (2018) Influence of redmud particle hybridization in banana/sisal and sisal/glass composites. Part Sci Technol 36:402–407. https://doi.org/10.1080/02726351.2016.1267284

Fuad MYA, Jamaludin M, Ishak ZAM (1993) Rice husk ash as fillers in polypropylene: a preliminary study. Polmeric Mater Polym Biomater 19:75–92. https://doi.org/10.1080/00914039308012019

Venkateswara Rao T, Venkatarao K, Lakshmi Kanth C (2014) Mechanical properties of bamboo fibre filled with fly ash filler reinforced hybrid composites. Eng Res Technol 3:725–732

Prabu VA, Manikandan V, Venkatesh R et al (2015) Influence of redmud filler on palmyra fruit and palmyra fiber waste reinforced polyester composite: hardness, tensile and impact studies. Mater Phys Mech 24:41–49

Nath S, Jena H, Deepak P (2019) Analysis of mechanical properties of jute epoxy composite with cenosphere filler. Silicon 11:659–671. https://doi.org/10.1007/s12633-018-9941-x

Omah AD, Omah EC, Offor PO et al (2018) Feasibility study on the use of carbonized cassava cortex as reinforcement in polymer- matrix composites. Cogent Eng 5:1–20. https://doi.org/10.1080/23311916.2018.1545557

Arumuga V, Uthayakumar M, Manikandan V et al (2014) Influence of redmud on the mechanical, dam** and chemical resistance properties of banana/polyester hybrid composites. Mater Des 64:270–279. https://doi.org/10.1016/j.matdes.2014.07.020

Prabu AVA, Johnson RDJ, Manikandan V (2017) Usage of industrial wastes as particulate composite for environment management: hardness, tensile and impact studies. Biochem Pharmacol 5:1289–1301. https://doi.org/10.1016/j.jece.2017.02.007

Raja RS, Manisekar K, Manikandan V (2014) Study on mechanical properties of fly ash impregnated glass fiber reinforced polymer composites using mixture design analysis. Mater Des 55:499–508. https://doi.org/10.1016/j.matdes.2013.10.026

Omah AD, Aigbodion VS, Madu SC et al (2018) Experimental correlation between the production parameter and mechanical properties of functional epoxy-cow bone particulate composites. J Adv Manuf Technol 101:2465–2474. https://doi.org/10.1007/s00170-018-3141-0

Baby A, Nayak SY, Heckadka SS, Purohit S, Keshav Kumar Bhagat LGT (2019) Mechanical and morphological characterization of carbonized egg-shell fillers/borassus fibre reinforced polyester hybrid composites. Mater Res Expr 6:1–32. https://doi.org/10.1088/2053-1591/ab3bb7

Patnaik A, Alok Satapathy SS, Mahapatra RRD (2009) A comparative study on different ceramic fillers affecting mechanical properties of glass: polyester composites. Reinf Plast Compos 28:1305–1318. https://doi.org/10.1177/0731684407086589

Sumesh KR, Kavimani V, Rajeshkumar G et al (2020) An investigation into the mechanical and wear characteristics of hybrid composites: influence of different types and content of biodegradable reinforcements. J Nat Fibers. https://doi.org/10.1080/15440478.2020.1821297

Atuanya CU, Ibhadode AOA, Dagwa IM (2012) Effects of breadfruit seed hull ash on the microstructures and properties of Al–Si–Fe alloy/breadfruit seed hull ash particulate composites. Results Phys 2:142–149. https://doi.org/10.1016/j.rinp.2012.09.003

Kumar BP, Birru AK (2017) Microstructure and mechanical properties of aluminium metal matrix composites with addition of bamboo leaf ash by stir casting method. Trans Nonferrous Met Soc China 27:2555–2572. https://doi.org/10.1016/S1003-6326(17)60284-X

Kumar KR, Pridhar T, Balaji VSS (2018) Mechanical properties and characterization of zirconium oxide (ZrO2) and coconut shell ash(CSA) reinforced aluminium (Al 6082) matrix hybrid composite. J Alloys Compd 765:171–179. https://doi.org/10.1016/j.jallcom.2018.06.177

Fatile OB, Akinruli JI, Amori AA (2014) Microstructure and mechanical behaviour of stir-cast Al–Mg–Sl alloy matrix hybrid composite reinforced with corn cob ash and silicon carbide. Eng Technol Innov 4:251–259

Kanayo K, Oluwatosin M, Awe AA (2016) Microstructure, mechanical and fracture properties of groundnut shell ash and silicon carbide dispersion strengthened aluminium matrix composites. J King Saud Univ 30:96–103. https://doi.org/10.1016/j.jksues.2016.01.001

Suleiman IY, Salihu SA, Mohammed TA (2018) Investigation of mechanical, microstructure, and wear behaviors of Al-12 % Si/reinforced with melon shell ash particulates. Adv Manuf Technol 97:4137–4144. https://doi.org/10.1007/s00170-018-2157-9

Kanayo K, Apata P (2013) Corrosion and wear behaviour of rice husk ash: alumina reinforced Al–Mg–Si alloy matrix hybrid composites. Integr Med Res 2:188–194. https://doi.org/10.1016/j.jmrt.2013.02.005

Shankar S, Balaji A, Kawin N (2018) Investigations on mechanical and tribological properties of Al–si10–mg alloy/sugarcane bagasse ash particulate composites. Part Sci Technol 36:762–770. https://doi.org/10.1080/02726351.2017.1301609

Zamri YB, Shamsul JB, Amin MM (2011) Potential of palm oil clinker as reinforcement in aluminium matrix composites for tribological applications. Mech Mater Eng 6:10–17

Dwivedi SP, Sharma S, Mishra RK (2016) Characterization of waste eggshells and CaCO 3 reinforced AA2014 green metal matrix composites: a green approach in the synthesis of composites. Precis Eng Manf 17:1383–1393. https://doi.org/10.1007/s12541-016-0164-z

Ariani F, Taher F, Hasibuan MS (2017) The analysis of composite properties reinforced with particles from palm oil industry waste produced by casting methods. Mater Sci Eng 277:1–9. https://doi.org/10.1088/1757-899X/277/1/012028

Skaria BP, Joy PP, Mathew S, Mathew G (2006) Lemongrass. In: KV P (ed) Handbook of Herbs and Spices. Woodhead Publishing Limited, England, pp 400–419

Morón Rodríguez F, Furones Mourelle JA, Pineda Gutiérrez Z (2017) Cymbopogon citratus. In: Kuete V (ed) Medicinal Spices and Vegetables from Africa. Elsevier Inc., pp 397–423

Abdulazeez MA, Abdullahi AS, James BD (2016) Lemongrass (Cymbopogon spp.) oils. In: Preedy VR (ed) Essential oils in food preservation, flavor and safety, 1st edn. Academic Press, Elsevier, pp 509–516

Han X, Parker TL (2017) Lemongrass (Cymbopogon flexuosus) essential oil demonstrated anti-inflammatory effect in pre-inflamed human dermal fibroblasts. Biochim Open 4:107–111. https://doi.org/10.1016/j.biopen.2017.03.004

Raja S, Rajesh R, Indran S, Divya D (2021) Characterization of industrial discarded novel Cymbopogon flexuosus stem fiber: a potential replacement for synthetic fiber. Ind Text. https://doi.org/10.1177/15280837211007507

Sass JE (1940) Elements of botanical micro technique, 1st edn. McGraw Hill Book Co., New York

O’Brien T, Feder N, McCull M (1964) Polyehromatic staining of plant cell walls by toluidine blue O. Protoplasma 59:364–373

Ganapathy T, Sathiskumar R, Senthamaraikannan P et al (2019) Characterization of raw and alkali treated new natural cellulosic fibres extracted from the aerial roots of banyan tree. Int J Biol Macromol 138:573–581. https://doi.org/10.1016/j.ijbiomac.2019.07.136

Manimaran P, Senthamaraikannan P, Sanjay MR et al (2018) Study on characterization of Furcraea foetida new natural fiber as composite reinforcement for lightweight applications. Carbohydr Polym 181:650–658. https://doi.org/10.1016/j.carbpol.2017.11.099

Vijay R, Singaravelu DL, Vinod A et al (2019) Characterization of raw and alkali treated new natural cellulosic fibers from Tridax procumbens. Int J Biol Macromol 125:99–108. https://doi.org/10.1016/j.ijbiomac.2018.12.056

Conrad CM (1944) Determination of wax in cotton fiber: a new alcohol extraction method. Ind Eng Chem 16:745–748

Segal CJJ, Conrad M (1958) Empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Indran S, Raj RE (2015) Characterization of new natural cellulosic fiber from Cissus quadrangularis stem. Carbohydr Polym 117:392–399. https://doi.org/10.1016/j.carbpol.2014.09.072

Warcholinski B, Kuznetsova TA, Gilewicz A et al (2018) Structural and mechanical properties of Zr–Si–N coatings deposited by arc evaporation at different substrate bias voltages. J Mater Eng Perform 27:3940–3950. https://doi.org/10.1007/s11665-018-3483-7

Warcholinski B, Gilewicz A, Lupicka O et al (2017) Structure of CrON coatings formed in vacuum arc plasma fluxes. Surf Coat Technol 309:920–930. https://doi.org/10.1016/j.surfcoat.2016.10.061

Cheary BYRW, Coelho A (2007) A fundamental parameters approach to X-ray line-profile fitting. Appl Crystallogr 25:109–121. https://doi.org/10.1107/S0021889891010804

Berger H (1986) Study of the K a emission spectrum of copper. X-Ray Spectrom 15:241–243. https://doi.org/10.1002/xrs.1300150405

Indran S, Raj RE (2014) Characterization of new natural cellulosic fiber from Cissus quadrangularis root. Carbohydr Polym 110:423–429. https://doi.org/10.1016/j.carbpol.2014.04.051

Sarki J, Hassan SB, Aigbodion VS, Oghenevweta JE (2011) Potential of using coconut shell particle fillers in eco-composite materials. J Alloys Compd 509:2381–2385. https://doi.org/10.1016/j.jallcom.2010.11.025

Dayo AQ, Gao B, Wang J et al (2017) Natural hemp fiber reinforced polybenzoxazine composites: curing behavior, mechanical and thermal properties. Compos Sci Technol 144:114–124. https://doi.org/10.1016/j.compscitech.2017.03.024

Kathirselvam M, Kumaravel A, Arthanarieswaran VP, Saravanakumar SS (2019) Characterization of cellulose fibers in Thespesia populnea barks: influence of alkali treatment. Carbohydr Polym 217:178–189. https://doi.org/10.1016/j.carbpol.2019.04.063

Binoj JS, Raj RE, Indran S (2018) Characterization of industrial discarded fruit wastes (Tamarindus Indica L.) as potential alternate for man-made vitreous fiber in polymer composites. Process Saf Environ Prot 116:527–534. https://doi.org/10.1016/j.psep.2018.02.019

Lim CJ, Arumugam M, Lim CK (2018) Mercerizing extraction and physicochemical characterizations of lignocellulosic fiber from the leaf waste of mikania micrantha kunth ex. Nat Fibers 17:726–737. https://doi.org/10.1080/15440478.2018.1527742

Prithiviraj M, Muralikannan R, Senthamaraikannan P (2016) Characterization of new natural cellulosic fiber from perotis indica plant. Polym Anal Charact 21:669–674. https://doi.org/10.1080/1023666X.2016.1202466

Sumesh KR, Kavimani V (2020) Mechanical, water absorption and wear characteristics of novel polymeric composites: impact of hybrid natural fibers and oil cake filler addition. Ind Text. https://doi.org/10.1177/1528083720971344

Johan E, Ogami K, Matsue N et al (2016) Fabrication of high purity silica from rice husk and its conversion into ZSM-5. Eng Appl Sci 11:4006–4010

Chakraverty A, Mishra P, Banerjee H (1988) Investigation of combustion of raw and acid-leached rice husk for production of pure amorphous white silica. Mater Sci 23:21–24. https://doi.org/10.1007/BF01174029

Adams FV, Ikotun BD, Patrick DO (2014) Characterization of rice hull ash and its performance in turbidity removal from water. Part Sci Technol 32:329–333. https://doi.org/10.1080/02726351.2013.867001

Imoisili PE, Ukoba KO, Jen TC (2019) Synthesis and characterization of amorphous mesoporous silica from palm kernel shell ash. Bol la Soc Esp Ceram y Vidr 59:159–164. https://doi.org/10.1016/j.bsecv.2019.09.006

Hossain SKS, Mathur L, Roy PK (2018) Rice husk/rice husk ash as an alternative source of silica in ceramics: a review. J Asian Ceram Soc 6:299–313. https://doi.org/10.1080/21870764.2018.1539210

Kauldhar BS, Yadav SK (2018) Turning waste to wealth: a direct process for recovery of nano-silica and lignin from paddy straw agro-waste. J Clean Prod 194:158–166. https://doi.org/10.1016/j.jclepro.2018.05.136

Rangaraj S, Venkatachalam R (2017) A lucrative chemical processing of bamboo leaf biomass to synthesize biocompatible amorphous silica nanoparticles of biomedical importance. Appl Nanosci 7:145–153. https://doi.org/10.1007/s13204-017-0557-z

Alves RH, Vitória T, Rovani S, Fungaro DA (2017) Green synthesis and characterization of biosilica produced from sugarcane waste ash. J Chem 17:1–9. https://doi.org/10.1155/2017/6129035

Moshi AAM, Ravindran D, Bharathi SRS et al (2020) Characterization of a new cellulosic natural fiber extracted from the root of Ficus religiosa tree. Int J Biol Macromol 142:212–221. https://doi.org/10.1016/j.ijbiomac.2019.09.094

Manimaran P, Prithiviraj M, Saravanakumar SS et al (2018) Physicochemical, tensile, and thermal characterization of new natural cellulosic fibers from the stems of Sida cordifolia. J Nat Fibers 15:860–869. https://doi.org/10.1080/15440478.2017.1376301

Anil A, Tomlal JE, George G et al (2016) Novel eco-friendly commingled polypropylene/banana fiber composite: studies on thermal and mechanical properties. Polym Bull 73:2987–3005. https://doi.org/10.1007/s00289-016-1636-0

Baskaran PG, Kathiresan M, Senthamaraikannan P, Saravanakumar SS (2018) Characterization of new natural cellulosic fiber from the bark of dichrostachys cinerea. J Nat Fibers 15:62–68. https://doi.org/10.1080/15440478.2017.1304314

Yaghoobi H, Fereidoon A (2018) An experimental investigation and optimization on the impact strength of kenaf fiber biocomposite: application of response surface methodology. Polym Bull 75:3283–3309. https://doi.org/10.1007/s00289-017-2212-y

Senthamaraikannan P, Kathiresan M (2018) Characterization of raw and alkali treated new natural cellulosic fiber from Coccinia grandis.L. Carbohydr Polym 186:332–343. https://doi.org/10.1016/j.carbpol.2018.01.072

Shim J, Velmurugan P, Oh B (2015) Extraction and physical characterization of amorphous silica made from corn cob ash at variable pH conditions via sol gel processing. J Ind Eng Chem 30:249–253. https://doi.org/10.1016/j.jiec.2015.05.029

Mathur L, Hossain SKS, Majhi MR, Roy PK (2017) Powder from biomass rice husk silica by solid-state route. Boletín la Soc Española Cerámica y Vidr. https://doi.org/10.1016/j.bsecv.2017.10.004

Dawit JB, Regassa Y, Lemu HG (2020) Property characterization of acacia tortilis for natural fiber reinforced polymer composite. Results Mater 5:1–19. https://doi.org/10.1016/j.rinma.2019.100054

Manimaran P, Saravanan SP, Sanjay MR et al (2019) Characterization of new cellulosic fiber: dracaena reflexa as a reinforcement for polymer composite structures. J Mater Res Technol 8:1952–1963. https://doi.org/10.1016/j.jmrt.2018.12.015

Yoganandam K, Ganeshan P, Nagarajaganesh B, Raja K (2019) Characterization studies on Calotropis procera fibers and their performance as reinforcements in epoxy matrix. J Nat Fibers 17:1706–1718. https://doi.org/10.1080/15440478.2019.1588831

Acknowledgements

SR acknowledges the Rohini College of Engineering and Technology, Shiv Kumar—copyeditor, and Pinnacle Bio-Sciences for providing research lab facilities to carry out his research work.

Funding

The author(s) received no financial support for the research, authorship, and/or publication of this article.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Soma Sundaram Pillai, R., Rajamoni, R., Suyambulingam, I. et al. Synthesis and characterization of cost-effective industrial discarded natural ceramic particulates from Cymbopogon flexuosus plant shoot for potential polymer/metal matrix reinforcement. Polym. Bull. 79, 8765–8806 (2022). https://doi.org/10.1007/s00289-021-03913-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-021-03913-5