Abstract

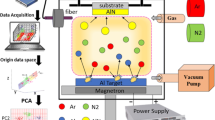

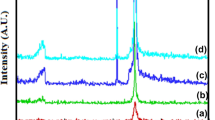

In this work, a unique approach in experiments was carried out by a pulsed DC sputtering for the 60/30-min process in one-step and multi-step (two- and four-step) deposition to obtain trends of residual stress and film properties of aluminum nitride (AlN). Film characteristics comparison between one-step and multi-step deposition was used to study the correlation among film crystallite orientation, residual stress, and film features. The thickness, microstructure, residual stress, and crystallite status of AlN films were examined by scanning electron microscopy (SEM), X-ray diffraction (XRD), Fourier transform infrared (FTIR) spectroscopy, and atomic force microscopy (AFM). The results show that the films have different stress characteristics in different microstructures when processed at the same amount of time in different deposition intervals. The increase in the degree of ion bombardment and induced substrate temperature raised leads to the interpretation of different microstructural changes in films. In this investigation, the film with thickness about 1300 nm for one-step deposition has a surface roughness of 2.67 nm, the grain size of 65.1 nm, and residual stress of 1575 MPa. In the four-step deposition, these values were reduced to 2.46 nm, 51.4 nm, and 841 MPa, respectively. In situ optical emission spectroscopy (OES) data were collected during plasma deposition of selected dominant wavelengths of N2 (315 and 336 nm) and Al (394 and 396 nm) for large-scale data analysis. Based on a cross-validation test executed from OES data preprocessing, the methodology with the principal component analysis (PCA) and value of microstructure characteristics (VMC) algorithm demonstrated that this unique multi-step deposition technique can provide a good stress gradient control from microstructural analysis and can effectively classify film characteristics in AlN film deposition.

Similar content being viewed by others

References

Oliveira IC, Grigorov KG, Maciel HS, Massi M, Otani C (2004) High textured AlN thin films grown by RF magnetron sputtering; composition, structure, morphology and hardness. Vacuum 75(4):331–338. https://doi.org/10.1016/j.vacuum.2004.04.001

Kelly PJ, Arnell RD (2000) Magnetron sputtering: a review of recent developments and applications. Vacuum 56(3):159–172. https://doi.org/10.1016/S0042-207X(99)00189-X

Sproul WD (1998) High-rate reactive DC magnetron sputtering of oxide and nitride superlattice coatings. Vacuum 51(4):641–646. https://doi.org/10.1016/S0042-207X(98)00265-6

Park MH, Kim SH (2012) Thermal conductivity of AlN thin films deposited by RF magnetron sputtering. Mater Sci Semicond Process 15(1):6–10. https://doi.org/10.1016/j.mssp.2011.04.007

Mehner H, Leopold S, Hoffmann M (2013) Variation of the intrinsic stress gradient in thin aluminum nitride films. J Micromech Microeng 23(9):095030. https://doi.org/10.1088/0960-1317/23/9/095030

Knisely KE, Hunt B, Troelsen B, Douglas E, Griffin BA, Stevens JE (2018) Method for controlling stress gradients in PVD aluminum nitride. J Micromech Microeng 28(11):115009. https://doi.org/10.1088/1361-6439/aad91a

Riah B, Camus J, Ayad A, Rammal M, Zernadji R, Rouag N, Djouadi MA (2021) Hetero-epitaxial growth of AlN deposited by DC magnetron sputtering on Si (111) using a AlN buffer layer. Coatings 11(9):1063. https://doi.org/10.3390/coatings11091063

Soussan P, O’Donnell K, D’Haen J, Vanhoyland G, Beyne EHA (2004) Tilmans Pulsed dc sputtered aluminum nitride: a novel approach to control stress and c-axis orientation. MRS OPL 833. https://doi.org/10.1557/PROC-833-G2.2

**ao S, Suzuki R, Miyake H, Harada S, Ujihara T (2018) Improvement mechanism of sputtered AlN films by high-temperature annealing. J Cryst Growth 502:41–44. https://doi.org/10.1016/j.jcrysgro.2018.09.002

Sheldon BW, Lau KHA, Rajamani A (2001) Intrinsic stress, island coalescence, and surface roughness during the growth of polycrystalline films. J Appl Phys 90(10):5097–5103. https://doi.org/10.1063/1.1412577

Shih HY, Lee WH, Kao WC, Chuang YC, Lin RM, Lin HC, Chen MJ (2017) Low-temperature atomic layer epitaxy of AlN ultrathin films by layer-by-layer, in-situ atomic layer annealing. Sci Rep 7(1):1–8. https://doi.org/10.1038/srep39717

Gamaleev V, Tsutsumi T, Hiramatsu M, Ito M, Hori M (2020) Generation and diagnostics of ambient air glow discharge in centimeter-order gaps. IEEE Access 8:72607–72619. https://doi.org/10.1109/ACCESS.2020.2988091

Joe Qin S (2003) Statistical process monitoring: basics and beyond. J Chemom 17(8-9):480–502. https://doi.org/10.1002/cem.800

Shojaei K, Mangolini L (2021) Application of machine learning for the estimation of electron energy distribution from optical emission spectra. J Phys D 54(26):265202. https://doi.org/10.1088/1361-6463/abf61e

Hong SJ, May GS, Park DC (2003) Neural network modeling of reactive ion etching using optical emission spectroscopy data. IEEE Trans Semicond Manuf 16(4):598–608. https://doi.org/10.1109/TSM.2003.818976

Jia X, ** C, Buzza M, Wang W, Lee J (2016) Wind turbine performance degradation assessment based on a novel similarity metric for machine performance curves. Renew Energy 99:1191–1201. https://doi.org/10.1016/j.renene.2016.08.018

Wang SH, Chang HE, Lee CC, Fuh YK, Li TT (2020) Evolution of a-Si: H to nc-Si: H transition of hydrogenated silicon films deposited by trichlorosilane using principle component analysis of optical emission spectroscopy. Mater Chem Phys 240:122186. https://doi.org/10.1016/j.matchemphys.2019.122186

Tan K, Chen S (2005) Adaptively weighted sub-pattern PCA for face recognition. Neurocomputing 64:505–511. https://doi.org/10.1016/j.neucom.2004.10.113

Lo HH, Chen WL, Wang PJ, Lai W, Fuh YK, Li TT (2022) Residual stress classification of pulsed DC reactive sputtered aluminum nitride film via large-scale data analysis of optical emission spectroscopy. J Adv Manuf Technol 119(11):7449–7462. https://doi.org/10.1007/s00170-022-08714-2

Kelly PJ, Henderson PS, Arnell RD, Roche GA, Carter D (2000) Reactive pulsed magnetron sputtering process for alumina films. J Vac Sci Technol A 18(6):2890–2896. https://doi.org/10.1116/1.1319679

Jiao X, Shi Y, Zhong H, Zhang R, Yang J (2015) AlN thin films deposited on different Si-based substrates through RF magnetron sputtering. J Mater Sci Mater Electron 26(2):801–808. https://doi.org/10.1007/s10854-014-2467-0

Zhang JX, Cheng H, Chen YZ, Uddin A, Yuan S, Geng SJ, Zhang S (2005) Growth of AlN films on Si (100) and Si (111) substrates by reactive magnetron sputtering. Surf Coat Technol 198(1-3):68–73. https://doi.org/10.1016/j.surfcoat.2004.10.075

Zhang X, Song XH, Zhang DL (2010) Thickness dependence of grain size and surface roughness for dc magnetron sputtered Au films. Chin Phys B 19(8):086802. https://doi.org/10.1088/1674-1056/19/8/086802

Martin F, Muralt P, Dubois MA, Pezous A (2004) Thickness dependence of the properties of highly c-axis textured AlN thin films. J Vac Sci Technol A 22(2):361–365. https://doi.org/10.1116/1.1649343

Giba AE, Pigeat P, Bruyère S, Easwarakhanthan T, Mücklich F, Horwat D (2017) Controlling refractive index in AlN films by texture and crystallinity manipulation. Thin Solid Films 636:537–545. https://doi.org/10.1016/j.tsf.2017.06.057

Kar JP, Bose G, Tuli S (2005) Influence of rapid thermal annealing on morphological and electrical properties of RF sputtered AlN films. Mater Sci Semicond Process 8(6):646–651. https://doi.org/10.1016/j.mssp.2006.04.001

Pobedinskas P, Bolsée JC, Dexters W, Ruttens B, Mortet V, D’Haen J, Manca JV, Haenen K (2012) Thickness dependent residual stress in sputtered AlN thin films. Thin Solid Films 522:180–185. https://doi.org/10.1016/j.tsf.2012.08.015

Abadias G, Chason E, Keckes J, Sebastiani M, Thompson GB, Barthel E, Dol GL, Murray CE, Stoessel CH, Martinu L (2018) Stress in thin films and coatings: current status, challenges, and prospects. J Vac Sci Technol A 36(2):020801. https://doi.org/10.1116/1.5011790

Lee HC, Lee JY, Ahn HJ (1994) Effect of the substrate bias voltage on the crystallographic orientation of reactively sputtered AlN thin films. Thin Solid Films 251(2):136–140. https://doi.org/10.1016/0040-6090(94)90678-5

Chodun R, Nowakowska-Langier K, Zdunek K (2015) Methods of optimization of reactive sputtering conditions of Al target during AlN films deposition. Mater Sci- Pol 33(4):894–901

Lee HC, Lee JY (1997) Effect of negative bias voltage on the microstructures of AlN thin films fabricated by reactive rf magnetron sputtering. J Mater Sci Mater Electron 8(6):385–390. https://doi.org/10.1023/A:1018551726015

Yang YP, Lu TY, Lo HH, Chen WL, Wang PJ, Lai W, Fuh YK, Li TT (2021) Machine learning assisted classification of aluminum nitride thin film stress via in-situ optical emission spectroscopy data. Materials 14(16):4445. https://doi.org/10.3390/ma14164445

Aveyard J, Bradley JW, McKay K, McBride F, Donaghy D, Raval R, D’Sa RA (2017) Linker-free covalent immobilization of nisin using atmospheric pressure plasma induced grafting. J Mater Chem B 5(13):2500–2510. https://doi.org/10.1039/C7TB00113D

Lee J (1996) Measurement of machine performance degradation using a neural network model. Comput Ind Eng 30(3):193–209. https://doi.org/10.1016/0166-3615(96)00013-9

Puggini L, McLoone S (2018) An enhanced variable selection and isolation forest based methodology for anomaly detection with OES data. Eng Appl Artif Intell 67:126–135. https://doi.org/10.1016/j.engappai.2017.09.021

Funding

This study was financially supported by Delta Electronics Inc., Taiwan and Department of Mechanical Engineering, National Central University, Taiwan.

Author information

Authors and Affiliations

Contributions

All authors contributed equally to the generation and analysis of experimental data, and the development of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, WL., Zhou, WY., Yuan, NH. et al. A multi-step deposited AlN films in a DC pulsed sputtering and film characteristics classification with principal component analysis of OES data. Int J Adv Manuf Technol 127, 2955–2967 (2023). https://doi.org/10.1007/s00170-023-11694-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11694-6