Abstract

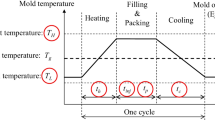

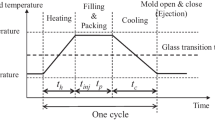

Weld line reduction is one of the major concerns in plastic injection molding (PIM) that results in high surface appearance and high strength of a plastic product. To resolve this issue, rapid heat cycle molding (RHCM) has attracted attention as an innovative PIM technology. In the RHCM, the mold temperature profile plays a crucial role in weld line reduction. On the other hand, high productivity as well as high surface appearance is also required in the PIM, and the trade-off between them will be observed. To achieve weld line reduction and high productivity simultaneously, it is important to adjust both the mold temperature profile and other process parameters in RHCM. A trial and error method is so widely used to adjust them, but it is much time-consuming task. In this paper, the mold temperature profile and several process parameters are optimized for the weld line reduction and the short cycle time. Therefore, multi-objective design optimization is performed. Numerical simulation in PIM is so intensive that a sequential approximate optimization using radial basis function is adopted to identify the Pareto frontier with a small number of simulations. The trade-off between the weld line reduction and the cycle time is clarified through the numerical result. Based on the numerical result, the experiment using a PIM machine (GL100, Sodick) is carried out. It has been confirmed through the numerical and experimental result that the proposed approach in RHCM is valid for the weld line reduction and the short cycle time.

Similar content being viewed by others

References

Yin F, Mao H, Hua L, Guo W, Shu M (2011) Back propagation neural network modeling for warpage prediction and optimization of plastic products during injection molding. Mater Des 32:1844–1850

Chen CC, Su PL, Lin YC (2009) Analysis and modeling of effective parameters for dimension shrinkage variation of injection molded part with thin shell feature using response surface methodology. Int J Adv Manuf Technol 45:1087–1095

Mathivanan D, Parthasarathy NS (2009) Sink-mark minimization in injection molding through response surface regression modeling and genetic algorithm. Int J Adv Manuf Technol 45:867–874

Wu CY, Ku CC, Pai HY (2011) Injection molding optimization with weld line design constraint using distributed multi-population genetic algorithm. Int J Adv Manuf Technol 52:131–141

Chen CS, Chen TJ, Chien RD, Chen SC (2007) Investigation on the weldline strength of thin-wall injection molded ABS parts. Int Commun Heat Mass Transfer 34:448–455

Ozcelik B (2011) Optimization of injection parameters for mechanical properties of specimens with weld line of polypropylene using Taguchi method. Int Commun Heat Mass Transfer 38:1067–1072

Deng YM, Zheng D, Lu XJ (2008) Injection moulding optimization of multi-class design variables using a PSO algorithm. Int J Adv Manuf Technol 39:690–698

Kim KH, Park JC, Suh YS, Koo BH (2017) Interactive robust optimal design of plastic injection products with minimum wedlines. Int J Adv Manuf Technol 88:1333–1344

Kitayama S, Tamada K, Takano M, Aiba S (2018) Numerical and experimental investigation on process parameters optimization in plastic injection molding for weldlines reduction and clam** force minimization. Int J Adv Manuf Technol 97:2087–2098

Dang XP (2014) General frameworks for optimization of plastic injection molding process parameters. Simul Model Pract Theory 41:15–27

Au KM, Yu KM (2007) A scaffolding architecture for conformal cooling design in rapid plastic injection moulding. Int J Adv Manuf Technol 34:496–515

Xu X, Sachs E, Allen S (2001) The design of conformal cooling channels in injection molding tooling. Polym Eng Sci 41(7):1265–1279

Shayfull Z, Sharif S, Zain AM, Ghazali MF, Saad RM (2014) Potential of conformal cooling channel in rapid heat cycle molding: a review. Adv Polym Technol 33(1). https://doi.org/10.1002/adv.21381

Au KM, Yu KM (2013) Conformal cooling channel design and CAE simulation for rapid blow mould. Int J Adv Manuf Technol 66:311–324

Zhang J, Wang J, Lin J, Guo Q, Chen K, Ma L (2016) Multiobjective optimization of injection molding process parameters based on Opt LHD, EBFNN, and MOPSO. Int J Adv Manuf Technol 85:2857–2872

Wang X, Li Z, Gu J, Ruan S, Shen C, Wang X (2016) Reducing service stress of the injection-molded polycarbonate window by optimizing mold construction and product structure. Int J Adv Manuf Technol 86:1691–1704

Kitayama S, Miyakawa H, Takano M, Aiba S (2017) Multi-objective optimization of injection molding process parameters for short cycle time and warpage reduction using conformal cooling channel. Int J Adv Manuf Technol 88:1735–1744

Chen SC, Lin YW, Chien RD, Li HM (2008) Variable mold temperature to improve surface quality of microcellular injection molded parts using induction heating technology. Adv Polym Technol 27(4):224–232

Li XP, Zhao GQ, Guan YJ, Ma MX (2009) Optimal design of heat channels for rapid heat cycle injection mold based on response surface and genetic algorithm. Mater Des 30:4317–4323

Jeng MC, Chen SC, Minh PS, Chang JA, Chung CS (2010) Rapid mold temperature control in injection molding by using steam heating. Int Commun Heat Mass Transfer 37:1295–1304

Wang G, Zhao G, Li H, Guan Y (2011) Multi-objective optimization design of the heating/cooling channels of the steam-heating rapid thermal response mold using particle swarm optimization. Int J Therm Sci 50:790–802

Wang M, Dong J, Wang W, Zhou J, Dai Z, Zhuang X, Yao X (2013) Optimal design of medium channels for water-assisted rapid thermal cycle mold using multi-objective evolutionary algorithm and multi-attribute decision-making method. Int J Adv Manuf Technol 68:2407–2417

**ao CL, Huang HX (2014) Optimal design of heating system for rapid thermal cycle mold using particle swarm optimization and finite element method. Appl Therm Eng 64:462–470

**ao CL, Huang HX (2014) Multiobjective optimization design of heating system in electric heating rapid thermal cycling mold for yielding high gloss parts. J Appl Polym Sci 131. https://doi.org/10.1002/APP.39976

Wang GL, Zhao GQ, Wang XX (2014) Heating/cooling channels design for an automotive interior part and its evaluation in rapid heat cycle molding. Mater Des 59:310–322

Wang X, Zhao G, Wang G (2013) Research on the reduction of sink mark and warpage of the molded part in rapid heat cycle molding process. Mater Des 47:779–792

Kitayama S, Arakawa M, Yamazaki K (2011) Sequential approximate optimization using radial basis function network for engineering optimization. Optim Eng 12:535–557

Kitayama S, Saikyo M, Nishio Y, Tsutsumi K (2016) Torque control strategy incorporating charge torque and optimization for fuel consumption and emissions reduction in parallel hybrid electric vehicles. Struct Multidiscip Optim 54:177–191

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kitayama, S., Ishizuki, R., Takano, M. et al. Optimization of mold temperature profile and process parameters for weld line reduction and short cycle time in rapid heat cycle molding. Int J Adv Manuf Technol 103, 1735–1744 (2019). https://doi.org/10.1007/s00170-019-03685-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03685-3