Abstract

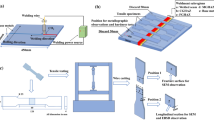

Weathered steel (S355J2W) joint was prepared by laser-metal active gas hybrid welding technique. The microstructures of the joint were examined with an optical microscope and a scanning electron microscope. Microhardness measurement, tensile test, side bend test, and Charpy impact test were conducted to examine the mechanical properties of the joint. Experimental results show that S355J2W steel joint has a nail head shape with three different zones: weld metal, heat-affected zone (composed of overheated zone, normalized zone, and incomplete normalized zone), and base metal. The highest microhardness of the joint is 280 HV. All the joint specimens failed in the base metal. Average tensile strength of 502.6 MPa and yield strength of 380.9 MPa were achieved. A bending angle of 180° was obtained for all the joint specimens, and a crack less than 3 mm was detected. The average values of absorbed energy for the weld are 198.7 and 79.1 J at −40 and −20 °C, respectively. All the specimens exhibited a level of toughness as indicated by deformation at the fracture surface.

Similar content being viewed by others

References

Melchers RE (2004) Effect of small compositional changes on marine immersion corrosion of low alloy steels. Corros Sci 46(7):1669–1674. doi:10.1016/j.corsci.2003.10.004

Yamashita M, Miyuki H, Matsuda Y (1994) The long term growth of the protective rust layer formed on weathering steel by atmospheric corrosion during a quarter of a century. Corros Sci 36(2):283–289. doi:10.1016/0010-938X(94)90158-9

Emilie LG, Muriel C, Remy F (2011) 3D heat transfer model of hybrid laser Nd:Yag-MAG welding of S355 steel and experimental validation. Int J Heat Mass Transf 54(7-8):1313–1322. doi:10.1016/j.ijheatmasstransfer.2010.12.010

Mahmoud M, Majid G, Jan F, Alexander F (2013) An investigation on stability of laser hybrid arc welding. Opt Lasers Eng 51(4):481–487. doi:10.1016/j.optlaseng.2012.10.016

Cao X, Wanjara P, Huang J, Munro C, Nolting A (2011) Hybrid fiber laser–arc welding of thick section high strength low alloy steel. Mater Des 32(6):3399–3413. doi:10.1016/j.matdes.2011.02.002

Liu L, Hao X (2009) Improvement of laser keyhole formation with the assistance of arc plasma in the hybrid welding process of magnesium alloy. Opt Lasers Eng 47(11):1177–1182. doi:10.1016/j.optlaseng.2009.06.003

Gleb T, Ekaterina V, Igor T, Alexander L, Olga V (2011) Observation of the mechanisms causing two kinds of undercut during laser hybrid arc welding. Appl Surf Sci 257(17):7501–7506. doi:10.1016/j.apsusc.2011.03.068

Song G, An G, Liu L (2012) Effect of gradient thermal distribution on butt joining of magnesium alloy to steel with Cu–Zn alloy interlayer by hybrid laser–tungsten inert gas welding. Mater Des 35:323–329. doi:10.1016/j.matdes.2011.09.006

Stute U, Kling R, Hermsdorf J (2007) Interaction between electrical arc and Nd:YAG laser radiation. Ann CIRP 56(1):197–200. doi:10.1016/j.cirp.2007.05.048

Kong F, Ma J, Radovan K (2011) Numerical and experimental study of thermally induced residual stress in the hybrid laser–GMA welding process. J Mater Process Technol 211(6):1102–1111. doi:10.1016/j.jmatprotec.2011.01.012

Çam G, Yeni Ç, Erim S, Ventzke V, Koçak M (1998) Investigation into properties of laser welded similar and dissimilar steel joints. Sci Technol Weld Join 3(4):177–189. doi:10.1179/1362171814Y.0000000247

Yi SK (2011) Welding materials and microstructure and properties of joint. Chemical Industry Press, Bei**g, p 204

Çam G, Erim S, Yeni Ç, Koçak M (1999) Determination of mechanical and fracture properties of laser beam welded steel joints. Weld J 78(6):193–201

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gu, X.Y., Duan, Z.Z., Gu, X.P. et al. Microstructure and mechanical properties of laser-MAG hybrid welded thick-section weathered steel joint. Int J Adv Manuf Technol 81, 825–831 (2015). https://doi.org/10.1007/s00170-015-7286-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7286-9