Abstract

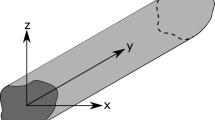

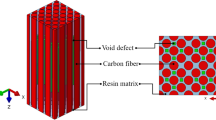

Matrix voids often appear in the process of manufacturing composite materials, and the existence of voids has a negative impact on the mechanical properties, especially the transverse mechanical properties, of composite materials. However, it will be costly to use experimental methods to determine the influence of matrix voids of different porosity on mechanical properties. This paper introduces a method of using finite element method to establish a randomly distributed matrix voids model, in order to analyze the change of mechanical properties of composite materials under different porosity conditions. Therefore, it provides a numerical calculation method with less computational cost and more efficient for studying the influence of matrix voids on the mechanical properties of the fiber-reinforced composite materials.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

孙盘滔.: 复合材料等同性试验. 科技尚品 3, 23(2016)

Mehdikhani, M., Gorbatikh, L., Verpoest, I., et al.: Voids in fiber-reinforced polymer composites: a review on their formation, characteristics, and effects on mechanical performance. J. Compos. Mater. 53(12), 1579–1669 (2019)

Hcab, C., Slac, D., Jw, E., et al.: A focused review on the thermo-stam** process and simulation progresses of continuous fibre reinforced thermoplastic composites. Compos. B Eng. 224, 109196 (2021)

Birt, E.A., Smith, R.A.: A review of NDE methods for porosity measurement in fibre-reinforced polymer composites. OR Insight 46(11), 681–686 (2021)

Hernandez, S., Sket, F., Gonzalez, C., et al.: Optimization of curing cycle in carbon fiber-reinforced laminates: Void distribution and mechanical properties. Compos. Sci. Technol. 85, 73–82 (2013)

Nikishkov, Y., Airoldi, L., Makeev, A.: Measurement of voids in composites by X-ray Computed Tomography. Compos. Sci. Technol. 89, 89–97 (2013)

Standard Test Methods for Void Content of Reinforced Plastics. ASTM

Hamidi, Y.K., Aktas, L., Altan, M.C.: Three-dimensional features of void morphology in resin transfer molded composites. Compos. Sci. Technol. 65(7–8), 1306–1320 (2005)

Patel, N., Rohatgi, V., Lee, L.J.: Micro scale flow behavior and void formation mechanism during impregnation through a unidirectional stitched fiberglass mat. Polym. Eng. Sci. 35(10), 837–851 (2010)

Liu, L., Zhang, B.M., Wang, D.F., et al.: Effects of cure cycles on void con-tent and mechanical properties of composite laminates. Compos. Struct. 73(3), 303–309 (2006)

Springer, G.S., Tang, J.M., Lee, W.I.: Effects of cure pressure on resin flow, voids, and mechanical properties. J. Compos. Mater. 21(5), 421–440 (1987)

Olivier, P., Cottu, J.P., Ferret, B.: Effects of cure cycle pressure and voids on some mechanical properties of carbon/epoxy laminates. Composites 26(7), 509–515 (1995)

Hernandez, S., Sket, F., Molina-Aldareguia, J.M., et al.: Effect of curing cycle on void distribution and interlaminar shear strength in polymer-matrix composites. Compos. Sci. Technol. 71(10), 1331–1341 (2011)

Guo, Z.S., Liu, L., Zhang, B.M., et al.: Critical void content for thermoset composite laminates. J. Compos. Mater. 43(17), 1775–1790 (2009)

Yoshida, H., Ogasa, T., Hayashi, R.: Statistical approach to the relationship between ILSS and void content of CFRP. Compos. Sci. Technol. 25(1), 3–18 (1986)

Wisnom, M.R., Reynolds, T., Gwilliam, N.: Reduction in interlaminar shear strength by discrete and distributed voids. Compos. Sci. Technol. 56(1), 93–101 (1996)

Kosmann, N., Karsten, J.M., Schuett, M., et al.: Determining the effect of voids in GFRP on the damage behaviour under compression loading using acoustic emission. Compos. Part B 70, 184–188 (2015)

Carraro, P.A., Maragoni, L., Quaresimin, M.: Influence of manufacturing induced defects on damage initiation and propagation in carbon/epoxy NCF laminates. Adv. Manuf. Polymer Compos. Sci. 1(1), 44–53 (2015)

Stamopoulos, A., Tserpes, K., Prucha, P., et al.: Evaluation of porosity effects on the mechanical properties of carbon fiber-reinforced plastic unidirectional laminates by X-ray computed tomography and mechanical testing. J. Compos. Mater. 50(15), 2087–2098 (2016)

Lei, Y., Yan, Y., Liu, Y., et al.: Microscopic failure mechanisms of fiber-reinforced polymer composites under transverse tension and compression. Compos. Sci. Technol. 72(15), 1818–1825 (2012)

Vajari, D.A., Gonzalez, C., Llorca, J., et al.: A numerical study of the influence of microvoids in the transverse mechanical response of unidirectional composites. Compos. Sci. Technol. 97(16), 46–54 (2014)

Vajari, A.D.: A micromechanical study of porous composites under longitudinal shear and transverse normal loading. Compos. Struct. 125, 266–276 (2015)

Li, B., Zhao, M.Y., Wan, X.P., et al.: Influence of irregular-void on transverse tensile mechanical properties of composites. Acta Materiae Compositae Sinica 36(2), 356–361 (2019)

Jiayue, W., Yin, Y., Zhongcheng, M., et al.: Peridynamic meso-scale modeling for degradation in transverse mechanical properties of composites with micro-void defects. Acta Mech. Solida Sinica 35(5), 813–823 (2022)

Taotao, Z., Ying, Y.: Micromechanical analysis of transverse damage of fibre-reinforced composites. Compos. Interfaces 23(1), 75–88 (2016)

Mark, R.G., Ghodrat, K.: Finite element micromechanics for stiffness and strength of wavy fiber composites. J. Compos. Mater. 38(4), 273–292 (2004)

Madenci, E., Barut, A., Phan, N.D.: Peridynamic unit cell homogenization. In: 58th AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference (2017)

Jiayue, W.: A Peridynamic analysis for effects of micro-void on transverse mechanical properties for unidirectional composites. Shanghai Jiao Tong University, Shanghai (China) (2022)

Acknowledgements

This work is supported by School of Aeronautic and Astronautic, Shanghai Jiao Tong University. Thanks for the detailed instruction from my tutors Dr. Hu and Dr. Yu. Their insightful suggestions always light me in the lost. The authors also gratefully acknowledge the helpful comments and suggestions of the reviews, which have improved the presentation.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Zhang, W., Yu, Y., Hu, Y., Li, H., Zhao, Z. (2024). A Finite Element Method of Research on Transverse Mechanical Properties of Fiber-Reinforced Composites with Random Matrix Void Defects. In: **g, Z., Zhan, X. (eds) Proceedings of the International Conference on Aerospace System Science and Engineering 2023. ICASSE 2023. Lecture Notes in Electrical Engineering, vol 1153. Springer, Singapore. https://doi.org/10.1007/978-981-97-0550-4_12

Download citation

DOI: https://doi.org/10.1007/978-981-97-0550-4_12

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-97-0549-8

Online ISBN: 978-981-97-0550-4

eBook Packages: EngineeringEngineering (R0)