Abstract

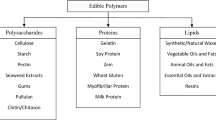

In the current scenario of the emerging nation, the development of edible food packaging in a laboratory or commercial scale has immensely attracted the growing manufacturers. Based on this, the current chapter addresses various targeted biomaterials and synthesis strategies for fabricating edible food packaging. The chapter introduces the characteristics attributes of available biomaterials including polysaccharides, proteins, lipids, fats, and their modification strategies to overcome the existing shortcomings of biopolymers such as poor water solubility, inferior mechanical properties, hydrophilicity, and others in edible food packaging. Further, the use of nanomaterials in edible films and coatings has provided additional benefits in obtaining improved product quality and shelf life. In this regard, a brief overview of using several nanosystems-assisted edible food packaging such as polymeric nanoparticles, inorganic nanofillers, biocomposites, nanoencapsulation, and nanoemulsion has been made. However, the successful development of edible food packaging and its commercialization depends on both selected materials and processing techniques. The edible food packaging is generally availed in the form of edible films and coatings being developed using different approaches with existing benefits and shortcomings. The various processes for fabricating edible coatings including dip**, spraying (conventional and electrospraying), drip**, foaming, fluidized bed coating, brushing, panning, etc., have been detailed. Additionally, the adopted methods for fabricating edible films are solution casting, extrusion, compression molding, blown films, etc. The selection of processing techniques for the development of edible food packaging is dependent on batch size, targeted food products, food properties, geometry of food products, and other attributes. Thus, both the materials property and synthesis strategies play a major role in develo** successful edible food packaging materials for highly perishable food products and others.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Bibliography

Otoni CG, Avena-Bustillos RJ, Azeredo HM, Lorevice MV, Moura MR, Mattoso LH, McHugh TH (2017) Recent advances on edible films based on fruits and vegetables—a review. Compr Rev Food Sci Food Saf 16:1151–1169. https://doi.org/10.1111/1541-4337.12281

Zambrano-Zaragoza ML, González-Reza R, Mendoza-Muñoz N, Miranda-Linares V, Bernal-Couoh TF, Mendoza-Elvira S, Quintanar-Guerrero D (2018) Nanosystems in edible coatings: a novel strategy for food preservation. Int J Mol Sci 19:705. https://doi.org/10.3390/ijms19030705

Baldwin EA, Nisperos-Carriedo MO, Baker RA (1995) Edible coatings for lightly processed fruits and vegetables. HortScience 30:35–37

de Moura MR, Aouada FA, Avena-Bustillos RJ, McHugh TH, Krochta JM, Mattoso LH (2009) Improved barrier and mechanical properties of novel hydroxypropyl methylcellulose edible films with chitosan/tripolyphosphate nanoparticles. J Food Eng 92:448–453. https://doi.org/10.1016/j.jfoodeng.2008.12.015

Navarro-Tarazaga ML, Massa A, Pérez-Gago MB (2011) Effect of beeswax content on hydroxypropyl methylcellulose-based edible film properties and postharvest quality of coated plums (Cv. Angeleno). LWT-Food Sci Technol 44:2328–2334. https://doi.org/10.1016/j.lwt.2011.03.011

Adler E (1977) Lignin chemistry—past, present and future. Wood Sci Technol 11:169–218. https://doi.org/10.1007/BF00365615

Cazón P, Velazquez G, Ramírez JA, Vázquez M (2017) Polysaccharide-based films and coatings for food packaging: a review. Food Hydrocoll 68:136–148. https://doi.org/10.1016/j.foodhyd.2016.09.009

de Dicastillo CL, Bustos F, Guarda A, Galotto MJ (2016) Cross-linked methyl cellulose films with murta fruit extract for antioxidant and antimicrobial active food packaging. Food Hydrocoll 60:335–344. https://doi.org/10.1016/j.foodhyd.2016.03.020

De Dicastillo CL, Rodríguez F, Guarda A, Galotto MJ (2016) Antioxidant films based on cross-linked methyl cellulose and native Chilean berry for food packaging applications. Carbohydr Polym 136:1052–1060. https://doi.org/10.1016/j.carbpol.2015.10.013

Rodrigues Filho G, de Assunçao RM, Vieira JG, Meireles CDS, Cerqueira DA, da Silva Barud H, Ribeiro SJ, Messaddeq Y (2007) Characterization of methylcellulose produced from sugar cane bagasse cellulose: crystallinity and thermal properties. Polym Degrad Stabil 92:205–210. https://doi.org/10.1016/j.polymdegradstab.2006.11.008

Aswathanarayan JB, Vittal RR (2019) Nanoemulsions and their potential applications in food industry. Front Sustain Food Syst 3:95

Otoni CG, Pontes SF, Medeiros EA, Soares NDF (2014) Edible films from methylcellulose and nanoemulsions of clove bud (Syzygium aromaticum) and oregano (Origanum vulgare) essential oils as shelf life extenders for sliced bread. J Agric Food Chem 62:5214–5219. https://doi.org/10.1021/jf501055f

Garcıa MA, Ferrero C, Bertola N, Martino M, Zaritzky N (2002) Edible coatings from cellulose derivatives to reduce oil uptake in fried products. Innov Food Sci Emerg Technol 3:391–397. https://doi.org/10.1016/S1466-8564(02)00050-4

Bilbao-Sáinz C, Avena-Bustillos RJ, Wood DF, Williams TG, McHugh TH (2010) Composite edible films based on hydroxypropyl methylcellulose reinforced with microcrystalline cellulose nanoparticles. J Agric Food Chem 58:3753–3760. https://doi.org/10.1021/jf9033128

Kaur R, Yadav N (2019) Biodegradable polymeric film for food packaging. J Appl Packag Res 11:2

Gennadios A, Hanna MA, Kurth LB (1997) Application of edible coatings on meats, poultry and seafoods: a review. LWT-Food Sci Technol 30:337–350. https://doi.org/10.1006/fstl.1996.0202

Khan MI, Adrees MN, Tariq MR, Sohaib M (2013) Application of edible coating for improving meat quality: a review. Pak J Food Sci 23:71–79

Bourtoom T (2008) Edible films and coatings: characteristics and properties. Int Food Res J 15:237–248

Romero-Bastida CA, Flores-Huicochea E, Martin-Polo MO, Velazquez G, Torres JA (2004) Compositional and moisture content effects on the biodegradability of zein/ethylcellulose films. J Agric Food Chem 52:2230–2235. https://doi.org/10.1021/jf0350414

Shi P, Zuo Y, Zou Q, Shen J, Zhang L, Li Y, Morsi YS (2009) Improved properties of incorporated chitosan film with ethyl cellulose microspheres for controlled release. Int J Pharm 375:67–74. https://doi.org/10.1016/j.ijpharm.2009.04.016

Li X, Jiang F, Ni X, Yan W, Fang Y, Corke H, **ao M (2015) Preparation and characterization of konjac glucomannan and ethyl cellulose blend films. Food Hydrocoll 44:229–236. https://doi.org/10.1016/j.foodhyd.2014.09.027

Guiga W, Swesi Y, Galland S, Peyrol E, Degraeve P, Sebti I (2010) Innovative multilayer antimicrobial films made with Nisaplin® or nisin and cellulosic ethers: physico-chemical characterization, bioactivity and nisin desorption kinetics. Innov Food Sci Emerg Technol 11:352–360. https://doi.org/10.1016/j.ifset.2010.01.008

Shit SC, Shah PM (2014) Edible polymers: challenges and opportunities. J Polym. https://doi.org/10.1155/2014/427259

Basch CY, Jagus RJ, Flores SK (2013) Physical and antimicrobial properties of tapioca starch-HPMC edible films incorporated with nisin and/or potassium sorbate. Food Bioproc Tech 6:2419–2428. https://doi.org/10.1007/s11947-012-0860-3

Jiménez A, Fabra MJ, Talens P, Chiralt A (2010) Effect of lipid self-association on the microstructure and physical properties of hydroxypropyl-methylcellulose edible films containing fatty acids. Carbohydr Polym 82:585–593. https://doi.org/10.1016/j.carbpol.2010.05.014

Sothornvit R (2009) Effect of hydroxypropyl methylcellulose and lipid on mechanical properties and water vapor permeability of coated paper. Food Res Int 42:307–311. https://doi.org/10.1016/j.foodres.2008.12.003

Osorio FA, Molina P, Matiacevich S, Enrione J, Skurtys O (2011) Characteristics of hydroxy propyl methyl cellulose (HPMC) based edible film developed for blueberry coatings. Procedia Food Sci 1:287–293. https://doi.org/10.1016/j.profoo.2011.09.045

Coma V, Sebti I, Pardon P, Pichavant FH, Deschamps A (2003) Film properties from crosslinking of cellulosic derivatives with a polyfunctional carboxylic acid. Carbohydr Polym 51:265–271. https://doi.org/10.1016/S0144-8617(02)00191-1

Hagenmaier RD, Shaw PE (1990) Moisture permeability of edible films made with fatty acid and hydroxypropyl methyl cellulose. J Agric Food Chem 38:1799–1803

Navarro-Tarazaga ML, Sothornvit R, Pérez-Gago MB (2008) Effect of plasticizer type and amount on hydroxypropyl methylcellulose–beeswax edible film properties and postharvest quality of coated plums (cv. Angeleno). J Agric Food Chem 56:9502–9509. https://doi.org/10.1021/jf801708k

Sakata Y, Shiraishi S, Otsuka M (2006) A novel white film for pharmaceutical coating formed by interaction of calcium lactate pentahydrate with hydroxypropyl methylcellulose. Int J Pharm 317:120–126. https://doi.org/10.1016/j.ijpharm.2006.02.058

Huichao W, Shouying D, Yang L, Ying L, Di WJJOC (2014) The application of biomedical polymer material hydroxy propyl methyl cellulose (HPMC) in pharmaceutical preparations. J Chem Pharm Res 6:155–160

Siepmann J, Peppas NAA (2012) Modeling of drug release from delivery systems based on hydroxypropyl methylcellulose (HPMC). Adv Drug Deliv Rev 64:163–174. https://doi.org/10.1016/j.addr.2012.09.028

Sebti I, Ham-Pichavant F, Coma V (2002) Edible bioactive fatty acid–cellulosic derivative composites used in food-packaging applications. J Agric Food Chem 50:4290–4294. https://doi.org/10.1021/jf0115488

De Moura MR, Avena-Bustillos RJ, McHugh TH, Wood DF, Otoni CG, Mattoso LH (2011) Miniaturization of cellulose fibers and effect of addition on the mechanical and barrier properties of hydroxypropyl methylcellulose films. J Food Eng 104:154–160. https://doi.org/10.1016/j.jfoodeng.2010.12.008

Vojdani F, Torres JA (1990) Potassium sorbate permeability of methylcellulose and hydroxypropyl methylcellulose coatings: effect of fatty acids. J Food Sci 55:841–846. https://doi.org/10.1111/j.1365-2621.1990.tb05244.x

Sánchez-González L, Vargas M, González-Martínez C, Chiralt A, Cháfer M (2009) Characterization of edible films based on hydroxypropylmethylcellulose and tea tree essential oil. Food Hydrocoll 23:2102–2109. https://doi.org/10.1016/j.foodhyd.2009.05.006

Pastor C, Sánchez-González L, Cháfer M, Chiralt A, González-Martínez C (2010) Physical and antifungal properties of hydroxypropylmethylcellulose based films containing propolis as affected by moisture content. Carbohydr Polym 82:1174–1183. https://doi.org/10.1016/j.carbpol.2010.06.051

Limmatvapirat S, Limmatvapirat C, Puttipipatkhachorn S, Nuntanid J, Luangtana-anan M (2007) Enhanced enteric properties and stability of shellac films through composite salts formation. Eur J Pharm Biopharm 67:690–698. https://doi.org/10.1016/j.ejpb.2007.04.008

Byun Y, Ward A, Whiteside S (2012) Formation and characterization of shellac-hydroxypropyl methylcellulose composite films. Food Hydrocoll 27:364–370. https://doi.org/10.1016/j.foodhyd.2011.10.010

Toğrul H, Arslan N (2004) Extending shelf-life of peach and pear by using CMC from sugar beet pulp cellulose as a hydrophilic polymer in emulsions. Food Hydrocoll 18:215–226. https://doi.org/10.1016/S0268-005X(03)00066-3

Su JF, Huang Z, Yuan XY, Wang XY, Li M (2010) Structure and properties of carboxymethyl cellulose/soy protein isolate blend edible films crosslinked by Maillard reactions. Carbohydr Polym 79:145–153. https://doi.org/10.1016/j.carbpol.2009.07.035

Kanatt SR, Makwana SH (2020) Development of active, water-resistant carboxymethyl cellulose-poly vinyl alcohol-Aloe vera packaging film. Carbohydr Polym 227:115303. https://doi.org/10.1016/j.carbpol.2019.115303

Kaur S, Dhillon GS (2014) The versatile biopolymer chitosan: potential sources, evaluation of extraction methods and applications. Crit Rev Microbiol 40:155–175. https://doi.org/10.3109/1040841X.2013.770385

Elsabee MZ, Abdou ES (2013) Chitosan based edible films and coatings: a review. Mater Sci Eng, C 33:1819–1841. https://doi.org/10.1016/j.msec.2013.01.010

Vásconez MB, Flores SK, Campos CA, Alvarado J, Gerschenson LN (2009) Antimicrobial activity and physical properties of chitosan–tapioca starch based edible films and coatings. Food Res Int 42:762–769. https://doi.org/10.1016/j.foodres.2009.02.026

van den Broek LA, Knoop RJ, Kappen FH, Boeriu CG (2015) Chitosan films and blends for packaging material. Carbohydr Polym 116:237–242. https://doi.org/10.1016/j.carbpol.2014.07.039

Aider M (2010) Chitosan application for active bio-based films production and potential in the food industry: review. LWT-Food Sci Technol 43:837–842. https://doi.org/10.1016/j.lwt.2010.01.021

Ghosh T, Katiyar V (2019) Chitosan-based edible coating: a customise practice for food protection. In: Katiyar V, Gupta R, Ghosh T (eds) Advances in sustainable polymers. Materials horizons: from nature to nanomaterials. Springer, Singapore. https://doi.org/10.1007/978-981-32-9804-0_8

Jiménez A, Fabra MJ, Talens P, Chiralt A (2012) Edible and biodegradable starch films: a review. Food Bioproc Tech 5:2058–2076. https://doi.org/10.1007/s11947-012-0835-4

Molavi H, Behfar S, Shariati MA, Kaviani M, Atarod S (2015) A review on biodegradable starch based film. J Microbiol Biotech Food Sci 4:456–461

Peressini D, Bravin B, Lapasin R, Rizzotti C, Sensidoni A (2003) Starch–methylcellulose based edible films: rheological properties of film-forming dispersions. J Food Eng 59:25–32. https://doi.org/10.1016/S0260-8774(02)00426-0

Bertuzzi MA, Vidaurre EC, Armada M, Gottifredi JC (2007) Water vapor permeability of edible starch based films. J Food Eng 80:972–978. https://doi.org/10.1016/j.jfoodeng.2006.07.016

Chaichi M, Hashemi M, Badii F, Mohammadi A (2017) Preparation and characterization of a novel bionanocomposite edible film based on pectin and crystalline nanocellulose. Carbohydr Polym 157:167–175. https://doi.org/10.1016/j.carbpol.2016.09.062

Kang HJ, Jo C, Kwon JH, Kim JH, Chung HJ, Byun MW (2007) Effect of a pectin-based edible coating containing green tea powder on the quality of irradiated pork patty. Food Control 18:430–435. https://doi.org/10.1016/j.foodcont.2005.11.010

Rodriguez-Garcia I, Cruz-Valenzuela MR, Silva-Espinoza BA, Gonzalez-Aguilar GA, Moctezuma E, Gutierrez-Pacheco MM, Ayala-Zavala JF (2016) Oregano (Lippia graveolens) essential oil added within pectin edible coatings prevents fungal decay and increases the antioxidant capacity of treated tomatoes. J Sci Food Agric 96:3772–3778. https://doi.org/10.1002/jsfa.7568

Guerreiro AC, Gago CM, Faleiro ML, Miguel MG, Antunes MD (2015) The use of polysaccharide-based edible coatings enriched with essential oils to improve shelf-life of strawberries. Postharvest Biol Tech 110:51–60. https://doi.org/10.1016/j.postharvbio.2015.06.019

Ngo TMP, Nguyen TH, Dang TMQ, Tran TX, Rachtanapun P (2020) Characteristics and antimicrobial properties of active edible films based on pectin and nanochitosan. Int J Mol Sci 21:2224. https://doi.org/10.3390/ijms21062224

Manrich A, Moreira FK, Otoni CG, Lorevice MV, Martins MA, Mattoso LH (2017) Hydrophobic edible films made up of tomato cutin and pectin. Carbohydr Polym 164:83–91. https://doi.org/10.1016/j.carbpol.2017.01.075

Stone AK, Nickerson MT (2012) Formation and functionality of whey protein isolate–(kappa-, iota-, and lambda-type) carrageenan electrostatic complexes. Food Hydrocoll 27:271–277. https://doi.org/10.1016/j.foodhyd.2011.08.006

Karbowiak T, Debeaufort F, Champion D, Voilley A (2006) Wetting properties at the surface of iota-carrageenan-based edible films. J Colloid Interface Sci 294:400–410. https://doi.org/10.1016/j.jcis.2005.07.030

Farhan A, Hani NM (2017) Characterization of edible packaging films based on semi-refined kappa-carrageenan plasticized with glycerol and sorbitol. Food Hydrocoll 64:48–58. https://doi.org/10.1016/j.foodhyd.2016.10.034

Largo DB, Fukami K, Nishijima T (1995) Occasional pathogenic bacteria promoting ice-ice disease in the carrageenan-producing red algae Kappaphycus alvarezii and Eucheuma denticulatum (Solieriaceae, Gigartinales, Rhodophyta). J Appl Phycol 7:545–554. https://doi.org/10.1007/BF00003941

Martins JT, Cerqueira MA, Bourbon AI, Pinheiro AC, Souza BW, Vicente AA (2012) Synergistic effects between κ-carrageenan and locust bean gum on physicochemical properties of edible films made thereof. Food Hydrocoll 29:280–289. https://doi.org/10.1016/j.foodhyd.2012.03.004

Ribeiro C, Vicente AA, Teixeira JA, Miranda C (2007) Optimization of edible coating composition to retard strawberry fruit senescence. Postharvest Biol Tech 44:63–70. https://doi.org/10.1016/j.postharvbio.2006.11.015

Arıca B, Çalış S, Kaş HS, Sargon MF, Hıncal AA (2002) 5-Fluorouracil encapsulated alginate beads for the treatment of breast cancer. Int J Pharm 242:267–269. https://doi.org/10.1016/S0378-5173(02)00172-2

Qin Y, Jiang J, Zhao L, Zhang J, Wang F (2018) Applications of alginate as a functional food ingredient. In: Biopolymers for food design. Academic Press, pp 409–429. https://doi.org/10.1016/B978-0-12-811449-0.00013-X

Rojas-Graü MA, Avena-Bustillos RJ, Olsen C, Friedman M, Henika PR, Martín-Belloso O, McHugh TH (2007) Effects of plant essential oils and oil compounds on mechanical, barrier and antimicrobial properties of alginate–apple puree edible films. J Food Eng 81:634–641. https://doi.org/10.1016/j.jfoodeng.2007.01.007

Bravin B, Peressini D, Sensidoni A (2006) Development and application of polysaccharide–lipid edible coating to extend shelf-life of dry bakery products. J Food Eng 76:280–290. https://doi.org/10.1016/j.jfoodeng.2005.05.021

Pérez-Gago MB, Rhim JW (2014) Edible coating and film materials: lipid bilayers and lipid emulsions. In: Innovations in food packaging. Academic Press, pp 325–350. https://doi.org/10.1016/B978-0-12-394601-0.00013-8

Morillon V, Debeaufort F, Blond G, Capelle M, Voilley A (2002) Factors affecting the moisture permeability of lipid-based edible films: a review. Crit Rev Food Sci Nutr 42:67–89. https://doi.org/10.1080/10408690290825466

Janjarasskul T, Krochta JM (2010) Edible packaging materials. Annu Rev Food Sci Technol 1:415–448

Fabra MJ, Jiménez A, Atarés L, Talens P, Chiralt A (2009) Effect of fatty acids and beeswax addition on properties of sodium caseinate dispersions and films. Biomacromol 10:1500–1507. https://doi.org/10.1021/bm900098p

Dangaran K, Tomasula PM, Qi P (2009) Structure and function of protein-based edible films and coatings. In: Edible films and coatings for food applications. Springer, New York, NY, pp 25–56. https://doi.org/10.1007/978-0-387-92824-1_2

Mohamed SA, El-Sakhawy M, El-Sakhawy MAM (2020) Polysaccharides, protein and lipid-based natural edible films in food packaging: a review. Carbohydr Polym 238:116178. https://doi.org/10.1016/j.carbpol.2020.116178

Mohamed SA, El-Sakhawy M, Nashy ESH, Othman AM (2019) Novel natural composite films as packaging materials with enhanced properties. Int J Biol Macromol 136:774–784. https://doi.org/10.1016/j.ijbiomac.2019.06.130

Teramoto H, Kakazu A, Yamauchi K, Asakura T (2007) Role of hydroxyl side chains in Bombyx mori silk sericin in stabilizing its solid structure. Macromolecules 40:1562–1569. https://doi.org/10.1021/ma062604e

Wang J, Shang J, Ren F, Leng X (2010) Study of the physical properties of whey protein: sericin protein-blended edible films. Eur Food Res Technol 231:109–116. https://doi.org/10.1007/s00217-010-1259-x

Marelli B, Brenckle MA, Kaplan DL, Omenetto FG (2016) Silk fibroin as edible coating for perishable food preservation. Sci Rep 6:25263. https://doi.org/10.1038/srep25263

Gontard N, Guilbert S, Cuq JL (1993) Water and glycerol as plasticizers affect mechanical and water vapor barrier properties of an edible wheat gluten film. J Food Sci 58:206–211. https://doi.org/10.1111/j.1365-2621.1993.tb03246.x

Embuscado ME, Huber KC (2009) Edible films and coatings for food applications, vol 222. Springer, London, New York

Guerrero P, Hanani ZN, Kerry JP, De La Caba K (2011) Characterization of soy protein-based films prepared with acids and oils by compression. J Food Eng 107:41–49. https://doi.org/10.1016/j.jfoodeng.2011.06.003

Shukla R, Cheryan M (2001) Zein: the industrial protein from corn. Ind Crops Prod 13:171–192. https://doi.org/10.1016/S0926-6690(00)00064-9

Azeredo HM, Mattoso LHC, Wood D, Williams TG, Avena‐Bustillos RJ, McHugh TH (2009) Nanocomposite edible films from mango puree reinforced with cellulose nanofibers. J Food Sci 74:N31–N35. https://doi.org/10.1111/j.1750-3841.2009.01186.x

McHugh TH, Huxsoll CC, Krochta JM (1996) Permeability properties of fruit puree edible films. J Food Sci 61:88–91. https://doi.org/10.1111/j.1365-2621.1996.tb14732.x

Mondal K, Ghosh T, Bhagabati P, Katiyar V (2019) Sustainable nanostructured materials in food packaging. In: Dynamics of advanced sustainable nanomaterials and their related nanocomposites at the bio-nano interface. Elsevier, Amsterdam, pp 171–213. https://doi.org/10.1016/B978-0-12-819142-2.00008-2

Valdés A, Burgos N, Jiménez A, Garrigós MC (2015) Natural pectin polysaccharides as edible coatings. Coatings 5:865–886. https://doi.org/10.3390/coatings5040865

Soares NM, Fernandes TA, Vicente AA (2016) Effect of variables on the thickness of an edible coating applied on frozen fish–establishment of the concept of safe dip** time. J Food Eng 171:111–118. https://doi.org/10.1016/j.jfoodeng.2015.10.016

Sipahi RE, Castell-Perez ME, Moreira RG, Gomes C, Castillo A (2013) Improved multilayered antimicrobial alginate-based edible coating extends the shelf life of fresh-cut watermelon (Citrullus lanatus). LWT-Food Sci Technol 51:9–15. https://doi.org/10.1016/j.lwt.2012.11.013

Cisneros-Zevallos L, Krochta JM (2003) Dependence of coating thickness on viscosity of coating solution applied to fruits and vegetables by dip** method. J Food Sci 68:503–510. https://doi.org/10.1111/j.1365-2621.2003.tb05702.x

Bazargani-Gilani B, Aliakbarlu J, Tajik H (2015) Effect of pomegranate juice dip** and chitosan coating enriched with Zataria multiflora Boiss essential oil on the shelf-life of chicken meat during refrigerated storage. Innov Food Sci Emerg Technol 29:280–287. https://doi.org/10.1016/j.ifset.2015.04.007

Petrou S, Tsiraki M, Giatrakou V, Savvaidis IN (2012) Chitosan dip** or oregano oil treatments, singly or combined on modified atmosphere packaged chicken breast meat. Int J Food Microbiol 156:264–271. https://doi.org/10.1016/j.ijfoodmicro.2012.04.002

Zhong Y, Cavender G, Zhao Y (2014) Investigation of different coating application methods on the performance of edible coatings on Mozzarella cheese. LWT-Food Sci Technol 56:1–8. https://doi.org/10.1016/j.lwt.2013.11.006

De León-Zapata MA, Sáenz-Galindo A, Rojas-Molina R, Rodríguez-Herrera R, Jasso-Cantu D, Aguilar CN (2015) Edible candelilla wax coating with fermented extract of tarbush improves the shelf life and quality of apples. Food Packag Shelf Life 3:70–75. https://doi.org/10.1016/j.fpsl.2015.01.001

Dave RK, Rao TR, Nandane AS (2017) Improvement of post-harvest quality of pear fruit with optimized composite edible coating formulations. J Food Sci Tech 54:3917–3927. https://doi.org/10.1007/s13197-017-2850-y

Del-Valle V, Hernández-Muñoz P, Guarda A, Galotto MJ (2005) Development of a cactus-mucilage edible coating (Opuntia ficus indica) and its application to extend strawberry (Fragaria ananassa) shelf-life. Food Chem 91:751–756. https://doi.org/10.1016/j.foodchem.2004.07.002

Rojas-Graü MA, Raybaudi-Massilia RM, Soliva-Fortuny RC, Avena-Bustillos RJ, McHugh TH, Martín-Belloso O (2007) Apple puree-alginate edible coating as carrier of antimicrobial agents to prolong shelf-life of fresh-cut apples. Postharvest Biol Technol 45:254–264. https://doi.org/10.1016/j.postharvbio.2007.01.017

Ghosh T, Teramoto Y, Katiyar V (2019) Influence of nontoxic magnetic cellulose nanofibers on chitosan based edible nanocoating: a candidate for improved mechanical, thermal, optical, and texture properties. J Agric Food Chem 67:4289–4299. https://doi.org/10.1021/acs.jafc.8b05905

Oms-Oliu G, Soliva-Fortuny R, Martín-Belloso O (2008) Edible coatings with antibrowning agents to maintain sensory quality and antioxidant properties of fresh-cut pears. Postharvest Biol Technol 50:87–94. https://doi.org/10.1016/j.postharvbio.2008.03.005

Roller S, Seedhar P (2002) Carvacrol and cinnamic acid inhibit microbial growth in fresh-cut melon and kiwifruit at 4 and 8 C. Lett Appl Microbiol 35:390–394. https://doi.org/10.1046/j.1472-765X.2002.01209.x

Menezes J, Athmaselvi KA (2016) Polysaccharide based edible coating on sapota fruit. Int Agrophys 30:4

Meng X, Li B, Liu J, Tian S (2008) Physiological responses and quality attributes of table grape fruit to chitosan preharvest spray and postharvest coating during storage. Food Chem 106:501–508. https://doi.org/10.1016/j.foodchem.2007.06.012

Silva-Vera W, Zamorano-Riquelme M, Rocco-Orellana C, Vega-Viveros R, Gimenez-Castillo B, Silva-Weiss A, Osorio-Lira F (2018) Study of spray system applications of edible coating suspensions based on hydrocolloids containing cellulose nanofibers on grape surface (Vitis vinifera L.). Food Bioproc Tech 11:1575–1585. https://doi.org/10.1007/s11947-018-2126-1

Andrade RD, Skurtys O, Osorio FA (2012) Atomizing spray systems for application of edible coatings. Compr Rev Food Sci Food Saf 11:323–337. https://doi.org/10.1111/j.1541-4337.2012.00186.x

Andrade R, Skurtys O, Osorio F (2013) Drop impact behavior on food using spray coating: fundamentals and applications. Food Res Int 54:397–405. https://doi.org/10.1016/j.foodres.2013.07.042

Park JH, Choi S, Moon HC, Seo H, Kim JY, Hong SP, Lee BS, Kang E, Lee J, Ryu DH, Choi IS (2017) Antimicrobial spray nanocoating of supramolecular Fe (III)-tannic acid metal-organic coordination complex: applications to shoe insoles and fruits. Sci Rep 7:6980. https://doi.org/10.1038/s41598-017-07257-x

Khan MKI, Schutyser M, Schroën K, Boom R (2014) Barrier properties and storage stability of edible coatings prepared with electrospraying. Innov Food Sci Emerg Technol 23:182–187. https://doi.org/10.1016/j.ifset.2014.03.001

Peretto G, Du WX, Avena-Bustillos RJ, Berrios JDJ, Sambo P, McHugh TH (2017) Electrostatic and conventional spraying of alginate-based edible coating with natural antimicrobials for preserving fresh strawberry quality. Food Bioproc Tech 10:165–174. https://doi.org/10.1007/s11947-016-1808-9

Khan MKI, Cakmak H, Tavman Ş, Schutyser M, Schroёn K (2014) Anti-browning and barrier properties of edible coatings prepared with electrospraying. Innov Food Sci Emerg Technol 25:9–13. https://doi.org/10.1016/j.ifset.2013.10.006

Khan MKI, Maan AA, Schutyser M, Schroën K, Boom R (2013) Electrospraying of water in oil emulsions for thin film coating. J Food Eng 119:776–780. https://doi.org/10.1016/j.jfoodeng.2013.05.027

Çakmak H (2017) Production of emulsion based edible coatings using electrospray method and their effects on the shelf-life of some fruits

Misir J, Brishti FH, Hoque MM (2014) Aloe vera gel as a novel edible coating for fresh fruits: a review. Am J Food Sci Technol 2:93–97. https://doi.org/10.12691/ajfst-2-3-3

Khare AK, Abraham RJ, Rao VA, Babu RN (2016) Utilization of carrageenan, citric acid and cinnamon oil as an edible coating of chicken fillets to prolong its shelf life under refrigeration conditions. Vet World 9:166–175. https://doi.org/10.14202/vetworld.2016.166-175

Kusrini E, Usman A, Wisakanti CD, Arbianti R, Nasution DA (2015) Improvement of quality of Carica papaya L. with clove oil as preservative in edible coating technology. Makara J Technol 19:148–152. https://doi.org/10.7454/mst.v19i3.3047

Ghanbarzadeh B, Almasi H, Entezami AA (2011) Improving the barrier and mechanical properties of corn starch-based edible films: effect of citric acid and carboxymethyl cellulose. Ind Crops Prod 33:229–235. https://doi.org/10.1016/j.indcrop.2010.10.016

Maran JP, Sivakumar V, Sridhar R, Thirugnanasambandham K (2013) Development of model for barrier and optical properties of tapioca starch based edible films. Carbohydr Polym 92:1335–1347. https://doi.org/10.1016/j.carbpol.2012.09.069

Maran JP, Sivakumar V, Sridhar R, Immanuel VP (2013) Development of model for mechanical properties of tapioca starch based edible films. Ind Crops Prod 42:159–168. https://doi.org/10.1016/j.indcrop.2012.05.011

Galus S, Kadzińska J (2015) Food applications of emulsion-based edible films and coatings. Trends Food Sci Technol 45:273–283. https://doi.org/10.1016/j.tifs.2015.07.011

Mu C, Guo J, Li X, Lin W, Li D (2012) Preparation and properties of dialdehyde carboxymethyl cellulose crosslinked gelatin edible films. Food Hydrocoll 27:22–29. https://doi.org/10.1016/j.foodhyd.2011.09.005

Krishna M, Nindo CI, Min SC (2012) Development of fish gelatin edible films using extrusion and compression molding. J Food Eng 108:337–344. https://doi.org/10.1016/j.jfoodeng.2011.08.002

Belyamani I, Prochazka F, Assezat G (2014) Production and characterization of sodium caseinate edible films made by blown-film extrusion. J Food Eng 121:39–47. https://doi.org/10.1016/j.jfoodeng.2013.08.019

Colak BY, Peynichou P, Galland S, Oulahal N, Assezat G, Prochazka F, Degraeve P (2015) Active biodegradable sodium caseinate films manufactured by blown-film extrusion: effect of thermo-mechanical processing parameters and formulation on lysozyme stability. Ind Crops Prod 72:142–151. https://doi.org/10.1016/j.indcrop.2014.12.047

Liu L, ** T, Liu CK, Hicks K, Mohanty AK, Bhardwaj R, Misra M (2008) A preliminary study on antimicrobial edible films from pectin and other food hydrocolloids by extrusion method. J Nat Fibers 5:366–382. https://doi.org/10.1080/15440470802460643

Liu L, Kerry JF, Kerry JP (2006) Effect of food ingredients and selected lipids on the physical properties of extruded edible films/casings. Int J Food Sci Tech 41:295–302. https://doi.org/10.1111/j.1365-2621.2005.01063.x

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Ghosh, T., Das, D., Katiyar, V. (2021). Edible Food Packaging: Targeted Biomaterials and Synthesis Strategies. In: Nanotechnology in Edible Food Packaging. Materials Horizons: From Nature to Nanomaterials. Springer, Singapore. https://doi.org/10.1007/978-981-33-6169-0_2

Download citation

DOI: https://doi.org/10.1007/978-981-33-6169-0_2

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-33-6168-3

Online ISBN: 978-981-33-6169-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)