Abstract

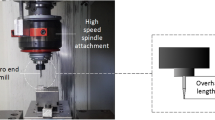

Micro-end milling is one of the widely used micromachining techniques in industries and research organizations to produce microfeatures having complex 3D shapes with high flexibility and high material removal rate. The analysis of areal surface roughness, surface defect, and microhardness are important for understanding the surface characteristics of the machined surface. This paper focused on the analysis of areal surface roughness, surface defect, and microhardness during micro-end milling on Inconel 718. Inconel 718, a nickel-based superalloy, was used as the workpiece material due to the superior properties such as high hardness, high strength to weight ratio, resistance to high-temperature loading, and corrosion resistance. Areal surface roughness and microhardness were taken as responses to understand their variations with feed per tooth at a constant depth of cut and speed. The feed per tooth is selected by giving importance to both inside and outside the size effect zone. It was observed that the areal surface roughness shows a decreasing trend initially at lower feed per tooth and then it shows an increasing trend outside the size effect region. The minimum value of areal surface roughness (Sa) was found to be in the range of 3 µm, which is the cutting edge radius of the tool. Inside the size effect zone, severe strain hardening was observed. Size effect in microhardness was also found. Inside the size effect region, the microhardness increases with feed per tooth and outside size effect region microhardness shows a decreasing trend.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Xavior, M.A., Patil, M., Maiti, A., Raj, M., Lohia, N.: Machinability studies on Inconel 718. Mater. Sci. Eng. Conf. 149, 1–8 (2016)

Vijay, V., Niharika, S., Srinivas, G., Praveen, K., Harish, C.B.: Review on machining characteristics and research prospects of conventional microscale machining operations. Mater. Manuf. Processes 32, 235–262 (2016)

Boswell, B., Islam, M.N., Davies, I.J.: A review of micro-mechanical cutting. Int. J. Adv. Manuf. Technol. 94, 789–806 (2018)

Ng, C.K., Melkote, S.N., Rahman, M., Kumar, A.S.: Experimental study of micro- and nano-scale cutting of aluminium 7075-T6. Int. J. Mach. Tools Manuf. 46, 929–936 (2006)

Min, S., Takeuchi, Y.: Recent advances in micro machining. Ann. CIRP 64, 134–141 (2006)

Lu, X., Jia, Z., Lu, Y., Feng, Y., Liang, S.Y.: Predicting the surface hardness of micro-milled nickel-base super alloy Inconel 718. Int. J. Adv. Manuf. Technol. (2017). https://doi.org/10.1007/s00170-017-0512-x

Fernando, B.O., Alessandro, R.R., Reginaldo, T.C., Adriano, F.S.: Size effect and minimum chip thickness in micro milling. Int. J. Adv. Manuf. Technol. 89, 39–54 (2015)

Vipindas, K., Annand, K.N., Mathew, J.: Effect of cutting edge radius on micro end milling: force analysis, surface roughness, and chip formation. Int. J. Adv. Manuf. Technol. 97, 711–722 (2018)

Hamed, R., Sadeghi, M.H., Budak, E.: Determination of minimum uncut chip thickness under various machining conditions during micro-end milling of Ti-6 Al-4V. Int. J. Adv. Manuf. Technol. 95, 1617–1634 (2018)

Kuram, E., Ozcelik, B.: Multi-objective optimization using Taguchi based grey relational analysis for micro-milling of Al 7075 material with ball nose end mill. Measurement 46(6), 1849–1864 (2013)

Vogler, M.P., DeVor, R.E., Kapoor, S.G.: On the modelling and analysis of machining performance in micro-end milling, part i: surface generation. J. Manuf. Sci. Eng. 126, 685–694 (2004)

Iturbe, A., Giraud, E., Hormaetxe, E., Garay, A., Germain, G., Ostolaza, K., Arrazola, P.J.: Mechanical characterization and modelling of Inconel 718 material behavior for machining process assessment. Mater. Sci. Eng., A 682, 441–453 (2017)

Aramcharoen, A., Mativenga, P.T.: Size effect and tool geometry in micro milling of tool steel. Precis. Eng. 33(4), 402–407 (2009)

Liu, X., DeVor, R.E., Kapoor, S.G.: Model-based analysis of the surface generation in micro end milling-part II: experimental validation and analysis. J. Manuf. Sc. Eng. 129, 461–469 (2007)

Elkaseer, A.M., Dimov, S.S., Pham, D., Popov, K.P., Olejnik, L., Rosochowski, A.: Material Microstructure Effects in Micro-End milling of Cu99.9E. Proc. Inst. Mech. Eng., Part B: J. Eng. Manuf. 232(7), 1143–1155 (2018)

Acknowledgements

The authors would like to sincerely thank the Department of Science and Technology (DST), Govt. of India, and Centre for Precision Measurements and Nano mechanical Testing, Department of Mechanical Engineering, National Institute of Technology Calicut, for providing support to carry out this work under the scheme ‘‘Fund for Improvement of Science and Technology’’ (No. SR/FST/ETI-388/2015).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Anand Krishnan, N., Venkatesh, G., Mathew, J. (2019). Investigations on the Influence of Size Effect on Surface Characteristics During Micro-End Milling of Inconel 718. In: Shunmugam, M., Kanthababu, M. (eds) Advances in Micro and Nano Manufacturing and Surface Engineering. Lecture Notes on Multidisciplinary Industrial Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-32-9425-7_15

Download citation

DOI: https://doi.org/10.1007/978-981-32-9425-7_15

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-32-9424-0

Online ISBN: 978-981-32-9425-7

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)