Abstract

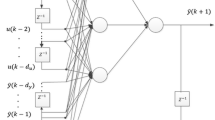

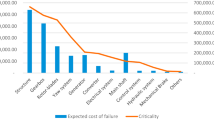

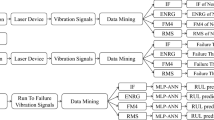

Engine failure prediction, to date, has become more challenging for adequately diagnosing and assigning appropriate maintenance decision-making processes. This paper investigates the health of an engine through experimental observation using an artificial neural network (ANN). Lubricating oil analysis has been performed for diagnosing quantitative analysis, i.e. wear particle concentration (WPC), severity index (SI), wear severity index (WSI), and percentage of large particles (PLP). An ANN model using a nonlinear autoregressive with exogenous input (NARX) architecture has been employed to predict quantitative outputs. Finally, a data-driven approach by applying an artificial neural network to understand the system degradation from accumulated condition monitoring data is studied. Topology 3–18–4 from NARX (ANN) was optimal in develo** a predictive failure model with regression coefficients (0.9985–0.9999), having an error autocorrelation factor bounded within 95% confidence limit and lowered MSE and MAPE values as 0.00093 and 3.56. The application of neural networks is increasingly attractive and seems to be the right choice for a data-driven diagnostic approach. In addition, the outcomes from the ANN data are validated with the experimental set so that the strength of the model is reflected and a pattern of failure from the historical monitoring of the operating engines is predicted.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Khan MI, Khan MA, Shakoor A (2018) A failure analysis of the exhaust valve from a heavy-duty natural gas engine. Eng Fail Anal 85:77–88

Hirani H (2009) Root cause failure analysis of outer ring fracture of four-row cylindrical roller bearing. Tribol Transac 52(2):180–190

Levi O, Eliaz N (2009) Failure analysis and condition monitoring of an open-loop oil system using ferrography. Tribol Lett 36:17–29

Biswas RK, Majumdar MC, Basu SK (2013) Vibration and oil analysis by ferrography for condition monitoring. J Inst Eng (India) Series C 94:267–274

Prajapati A, Bechtel J, Ganesan S (2012) Condition-based maintenance: a survey. J Quality Mainten Eng

Mobley RK (2002) An introduction to predictive maintenance. Elsevier

Asgari H, Chen X, Morini M, Pinelli M, Sainudiin R, Spina PR, Venturini M (2016) NARX models for simulation of the start-up operation of a single-shaft gas turbine. Appl Therm Eng 93:368–376

Kiakojoori S, Khorasani K (2016) Dynamic neural networks for gas turbine engine degradation prediction, health monitoring and prognosis. Neural Comput Appl 27(8):2157–2192

Lu PJ, Zhang MC, Hsu TC, Zhang J (2001) An evaluation of engine faults diagnostics using artificial neural networks. J Eng Gas Turbines Power 123(2):340–346

Laghari MS, Boujarwah A (1999) Wear particle texture classification using artificial neural networks. Int J Pattern Recognit Artif Intell 13(03):415–428

Huang ZY, Yu ZQ, Li ZX, Geng YC (2010) A fault diagnosis method of rolling bearing through wear particle and vibration analyses. Appl Mech Mater 26:676–681

Li Q, Zhao T, Zhang L, Sun W, Zhao X (2017) Ferrography wear particles image recognition based on extreme learning machine. J Electr Comput Eng

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Mohanty, S., Paul, S. (2023). Application of Artificial Intelligence for Failure Prediction of Engine Through Condition Monitoring Technique. In: Dixit, U.S., Kanthababu, M., Ramesh Babu, A., Udhayakumar, S. (eds) Advances in Forming, Machining and Automation. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-3866-5_36

Download citation

DOI: https://doi.org/10.1007/978-981-19-3866-5_36

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-3865-8

Online ISBN: 978-981-19-3866-5

eBook Packages: EngineeringEngineering (R0)