Abstract

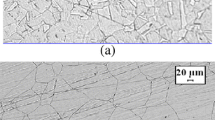

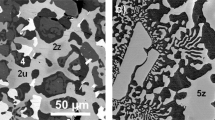

During nuclear reprocessing and waste storage conditions in highly oxidizing nitric acid media, trans-passive corrosion attacks occur, i.e., corrosion potential is shifted to noble direction near or over the passive region, and stainless steel (SS) suffers severe intergranular corrosion (IGC) even if the steel is not sensitized. In this work, corrosion behavior in simulated non-radioactive PUREX environment with different oxidizing species (Nd3+, Mo6+ and Cs+, corrosion product Fe3+, and surrogate element V5+, etc.) on AISI type 304L SS in different concentrations (2, 6, and 8 M) of nitric acid has been evaluated. The electrochemical corrosion behavior was evaluated by open circuit potential (OCP) and potentiodynamic anodic polarization methods. The electrochemical corrosion test results indicated a shift in the corrosion potential with the metallic ions concentration to a more noble potential towards the trans-passive region. No significant change in the breakdown potential was observed. The composition of the surface film has been evaluated by X-ray Photoelectron Spectroscopy (XPS). The three-phase corrosion test in boiling liquid, vapor, and condensate phases (similar to the ASTM A-262 Practice-C test) in simulated dissolver conditions in 2, 6, and 8 M nitric acid solution with or without oxidizing ions have also been studied. Surface morphology of the corrosion tested samples were examined by an optical microscope, which indicated severe intergranular corrosion (IGC) attack in the boiling liquid phase. In summary, oxidizing species and higher nitric acid concentration enhance the IGC attack in type 304L SS. The role of metallic ion species on IGC of type 304LSS is also highlighted.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Fauvet P, Balbaud F, Robin R, Tran QT, Mugnier A, Espinoux D (2008) Corrosion mechanisms of austenitic stainless steels in nitric media used in reprocessing plants. J Nucl Mater 375:52–64. https://doi.org/10.1016/j.jnucmat.2007.10.017

Gwinner B, Auroy M, Balbaud CF, Fauvet P, Larabi GN, Laghoutarisa P, Robin R (2016) Towards a reliable determination of the intergranular corrosion rate of austenitic stainless steel in oxidizing media. Corros Sci 107:60–75. https://doi.org/10.1016/j.corsci.2016.02.020

Sedriks AJ (1996) Corrosion of stainless steels, 2nd edn. Wiley-Interscience, New York

ASTM Designation (2014) Standard practices for detecting susceptibility to intergranular attack in austenitic stainless steels, vol A-262, pp 1– 20

Mudali UK, Dayal RK, Gnanmoorthy JB (1993) Corrosion studies on materials of construction for spent nuclear fuel reprocessing plant equipment. J Nucl Mater 203:73–82. https://doi.org/10.1016/0022-3115(93)90432-X

Raj B, Mudali UK (2006) Materials development and corrosion problems in nuclear fuel reprocessing plants. Prog Nucl Energy 48:283–313. https://doi.org/10.1016/j.pnucene.2005.07.001

Pelle J, Gruet N, Gwinner B, Schlegel ML, Vivier V (2020) On the role of Fe(III) ions on the reduction mechanisms of concentrated nitric acid. Electrochim Acta 335:135578. https://doi.org/10.1016/j.electacta.2019.135578

Ningshen S, Mudali UK, Ramya S, Raj B (2011) Corrosion behaviour of AISI type 304L stainless steel in nitric acid media containing oxidizing species. Corros Sci 53:64–70. https://doi.org/10.1016/j.corsci.2010.09.023

Shit G, Ningshen S (2019) The corrosion behavior of compositional modified AISI type 304L stainless steel for nitric acid application. Anti-Corros Methods Mater 66:149–158. https://doi.org/10.1108/ACMM-02-2018-1906

Bhise S, Kain V (2012) Methodology based on potential measurement for predicting corrosion behaviour of SS 304L in boiling nitric acid containing oxidizing ions. Corros Eng Sci Technol 47:61–69. https://doi.org/10.1179/1743278211Y.0000000016

Hasegawa S, Kima SY, Ebina T, Tokuda H, Ito T, Nagano N, Hitomia K, Ishiia K (2016) Effect of nitrate on Corrosion of austenitic stainless steel in boiling nitric acid solution containing chromium ions. J Nucl Sci Technol 53:1332–1341. https://doi.org/10.1080/00223131.2015.1107514

Kolman DG, Ford DK, Butt DP, Nelson TO (1997) Corrosion of 304 stainless steel exposed to nitric acid-chloride environments. Corros Sci 39:2067–2093. https://doi.org/10.1016/S0010-938X(97)00092-9

Motooka T, Kato C, Yamamoto M (2010) Effect of re-oxidation rate of chromium and vanadium ions on corrosion rate of stainless steel in boiling nitric acid solutions. Zairyo-to-Kankyo 59:18–24 (Japanese). https://doi.org/10.3323/JCORR.59.18

Irisawa E, Yamamoto M, Kato C, Motooka T, Ban Y (2019) Effect of re-oxidation rate of additive cations on corrosion rate of stainless steel in boiling nitric acid solution. J Nucl Sci Technol 56:337–344. https://doi.org/10.1080/00223131.2019.1580624

Kain V, De PK (2005) Controlling corrosion in the back end of fuel cycle using nitric acid grade stainless steels. Int J Nucl Energy Sci Technol 1:220–231. https://doi.org/10.1504/IJNEST.2005.007146

Balbaud F, Sancheza G, Fauveta P, Santarinia G, Picard G (2000) Mechanism of corrosion of AISI 304L stainless steel in the presence of nitric acid condensates. Corros Sci 42:1685–1707. https://doi.org/10.1016/S0010-938X(00)00021-4

Laurent B, Gruet N, Gwinner B, Miserque F, Rousseau K, Ogle K (2017) The kinetics of transpassive dissolution chemistry of stainless steels in nitric acid: the impact of Si. Electrochim Acta 258:653–661. https://doi.org/10.1016/j.electacta.2017.11.110

Acknowledgements

The authors like to acknowledge IGCAR management for active support towards this research work.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Shit, G., Pooonguzhali, A., Ningshen, S. (2022). Effect of Metallic Ion Species on Nitric Acid Corrosion of Type 304L Stainless Steel. In: Mudali, U.K., Aruna, S.T., Nagaswarupa, H.P., Rangappa, D. (eds) Recent Trends in Electrochemical Science and Technology. Springer Proceedings in Materials, vol 15. Springer, Singapore. https://doi.org/10.1007/978-981-16-7554-6_2

Download citation

DOI: https://doi.org/10.1007/978-981-16-7554-6_2

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-7553-9

Online ISBN: 978-981-16-7554-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)