Abstract

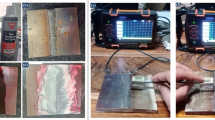

There is insufficient information available in existing welding standards, codes and specifications regarding the implications of having two or several adjacently fabricated weld joints in close proximity. This has introduced fatigue life performance uncertainties, due to a lack of understanding of the inherent behaviour of weld joints in the presence of adjacent welds. Hence, it is vital to investigate the fatigue life performance and obtain quantitative data for future assessments. This experiment has been designed using six welded, and one unwelded, S420G2+M 500 × 300 × 15 mm structural steel plate. Two of these plates were used for fatigue testing, having 44 mm and 12 mm between the adjacent weld toes. These distances were less than normally recommended in standards codes and specifications. The preparation of the samples was conducted in accordance with ASTM E466-15 for homogenous materials subjected to high-cycle fatigue. The experiment was not able to detect any detrimental effect by having welds in close proximity using this specific preparation method and weld setup. The weld metal and corresponding heat-affected zones had a higher fatigue strength than that of the surrounding base material. All tested specimens failed in the base metal. The material and welding method did not seem to introduce any degrading effect on the weld joint. Important to note is that the fabrication method required a surface roughness of 0.2 µm and had likely introduced an outer layer of compressive residual stresses at yield point level 50 µm into the surface and bottom surfaces of the specimens. This might have improved the resistance to crack formation in the surface. The residual stress was obtained by using ultrasonic stress measurement technique and x-ray diffraction presented in a parallel study by the same authors.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Specification for Class I arc welding of ferritic steel pipework for carrying fluids, BS 2633, 1987.

Class II arc welding of carbon steel pipework for carrying of fluids, BS 2971, 1991.

Specification for welding of steel pipelines on land and offshore, BS 4515, 2009.

Specification for Unfired fusion welded pressure vessels, PD5500, 2012.

Standard Practice for Presentation of Constant Amplitude Fatigue Test Results for Metallic Materials, E468 − 11, 2011.

Standard Practice for Conducting Force Controlled Constant Fatigue Tests of Metallic Materials, ASTM E466–15, 2015.

Weldable structural steels for fixed offshore structures - Technical delivery conditions, NS-EN 10225, 2009.

Definition and classification of grades of steel, NS-EN 10020, 2000.

Welding — Guidelines for a metallic materials grou** system, ISO/TR 15608, 2017.

Welding — Grou** systems for materials — European materials, ISO/TR 20172, 2009.

Specification and qualification of welding procedures for metallic materials Welding procedure test Part 1: Arc and gas welding of steels and arc welding of nickel and nickel alloys, NS-EN ISO 15614–1, 2017.

Boyer HE (1986) Atlas of fatigue curves. American Society for Metals, Metals Park, Ohio

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Larsson, M., Larsson, M., Ratnayake, R.M.C. (2021). Investigation of Fatigue Strength Behaviour in Dual Weld S420 Steel Joints Fabricated at a Close Proximity. In: Abdel Wahab, M. (eds) Proceedings of 1st International Conference on Structural Damage Modelling and Assessment. Lecture Notes in Civil Engineering, vol 110. Springer, Singapore. https://doi.org/10.1007/978-981-15-9121-1_27

Download citation

DOI: https://doi.org/10.1007/978-981-15-9121-1_27

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-9120-4

Online ISBN: 978-981-15-9121-1

eBook Packages: EngineeringEngineering (R0)