Abstract

Hydrogen embrittlement is an important phenomenon where the mechanical properties of a metallic material are degraded in the presence of hydrogen, sometimes leading to a change in the failure mode of the metallic material. Although mechanical failures due to hydrogen embrittlement have been observed for over a century, the atomic-level mechanisms associated with the hydrogen embrittlement process are still under debate. In this chapter, atomistic simulation efforts focused on hydrogen segregation and hydrogen embrittlement are reviewed. Atomistic simulation methods provide a nanoscale modeling technique capable of studying the role of hydrogen atoms on dislocation nucleation, crack propagation, and grain boundary decohesion. Examples are provided in this chapter of the use of a site-energy selection method to study hydrogen segregation and molecular dynamics simulations to study hydrogen-induced grain boundary decohesion in nickel. Grain boundary strength and work of separation in the presence of segregated hydrogen are computed from the molecular dynamics simulations. Subsequently, this data may be used in higher length scale models and simulations of the hydrogen embrittlement process.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Johnson WH. On some remarkable changes produced in iron and steels by the action of hydrogen acids. Proc R Soc Lond. 1875;23:168–75.

Carneiro R, Ratnapuli RC, Lins VFC. The influence of chemical composition and microstructure of API linepipe steels on hydrogen induced cracking and sulfide stress corrosion cracking. Mater Sci Eng A. 2003;357(1):104–10.

Dingreville R, Karnesky RA, Puel G, Schmitt J-H. Review of the synergies between computational modeling and experimental characterization of materials across length scales. J Mater Sci. 2016;51(3):1178–203.

Louthan MR, Caskey GR, Donovan JA, Rawl DE. Hydrogen embrittlement of metals. Mater Sci Eng. 1972;10:357–68.

Gest RJ, Troiano AR. Stress corrosion and hydrogen embrittlement in an aluminum alloy. Corrosion. 1974;30(8):274–9.

Northwood DO, Kosasih U. Hydrides and delayed hydrogen cracking in zirconium and its alloys. Int Met Rev. 1983;28(1):92–121.

Shih DS, Robertson IM, Birnbaum HK. Hydrogen embrittlement of α titanium: in situ TEM studies. Acta Metall. 1988;36(1):111–24.

Wang M, Akiyama E, Tsuzaki K. Effect of hydrogen on the fracture behavior of high strength steel during slow strain rate test. Corros Sci. 2007;49(11):4081–97.

Wang S, Martin ML, Robertson IM, Sofronis P. Effect of hydrogen environment on the separation of Fe grain boundaries. Acta Mater. 2016;107:279–88.

Robertson IM, Sofronis P, Nagao A, Martin ML, Wang S, Gross DW, Nygren KE. Hydrogen embrittlement understood. Metall Mater Trans B. 2015;46(3):1085–103.

Lynch S. Hydrogen embrittlement phenomena and mechanisms. Corros Rev. 2012;30(3–4):105–23.

Westlake DG. A generalized model for hydrogen embrittlement. Trans Am Soc Met. 1969;62:1000–6.

Birnbaum HK. Mechanisms of hydrogen related fracture of metals; 1989. Technical report, DTIC Document.

Ells CE. Hydride precipitates in zirconium alloys (a review). J Nucl Mater. 1968;28(2):129–51.

Pfeil LB. The effect of occluded hydrogen on the tensile strength of iron. Proc R Soc Lond. Ser A, Containing Papers of a Mathematical and Physical Character. 1926;112(760):182–95.

Troiano AR. The role of hydrogen and other interstitials in the mechanical behavior of metals. Trans Am Soc Met. 1960;52(1):54–80.

Hirth JP, Rice JR. On the thermodynamics of adsorption at interfaces as it influences decohesion. Metall Trans A. 1980;11(9):1501–11.

Kirchheim R. Reducing grain boundary, dislocation line and vacancy formation energies by solute segregation. I. Theoretical background. Acta Mater. 2007;55(15):5129–38.

Knott JF. Fracture toughness and hydrogen-assisted crack growth in engineering alloys, In Hydrogen effects in materials (eds A. W. Thompson and N. R. Moody), John Wiley & Sons, Inc., Hoboken, NJ, USA, 1994. https://doi.org/10.1002/9781118803363.ch36

Sofronis P, Robertson IM. Viable mechanisms of hydrogen embrittlement – A review. In: Hydrogen in matter: a collection from the papers presented at the second International Symposium on Hydrogen in Matter (ISOHIM), vol. 837. Melville: AIP Publishing; 2006. p. 64–70.

Kameda J, McMahon CJ. Solute segregation and hydrogen-induced intergranular fracture in an alloy steel. Metall Trans A. 1983;14(4):903–11.

Dadfarnia M, Schembri PE, Sofronis P, Foulk JW III, Nibur KA, Balch DK, et al. On modeling hydrogen-induced crack propagation under sustained load. JOM. 2014;66(8):1390–8.

Hirth JP. Effects of hydrogen on the properties of iron and steel. Metall Trans A. 1980;11(6):861–90.

Mishin Y, Sofronis P, Bassani JL. Thermodynamic and kinetic aspects of interfacial decohesion. Acta Mater. 2002;50(14):3609–22.

Beachem CD. A new model for hydrogen-assisted cracking (hydrogen “embrittlement”). Metall Trans. 1972;3(2):441–55.

Ferreira PJ, Robertson IM, Birnbaum HK. Hydrogen effects on the interaction between dislocations. Acta Mater. 1998;46(5):1749–57.

Abraham DP, Altstetter CJ. Hydrogen-enhanced localization of plasticity in an austenitic stainless steel. Metall Mater Trans A. 1995;26(11):2859–71.

Sofronis P, Robertson IM. Transmission electron microscopy observations and micromechanical/continuum models for the effect of hydrogen on the mechanical behaviour of metals. Philos Mag A. 2002;82(17–18):3405–13.

Lynch SP. Environmentally assisted cracking: overview of evidence for an adsorption-induced localised-slip process. Acta Metall. 1988;36(10):2639–61.

Lynch SP. Metallographic contributions to understanding mechanisms of environmentally assisted cracking. Metallography. 1989;23(2):147–71.

Cox BN, Bauschlicher CW. Surface relaxation and induced stress accompanying the adsorption of H upon Be (0001). Surf Sci. 1981;102(2–3):295–311.

Oriani RA. On the possible role of the surface stress in environmentally induced embrittlement and pitting. Scr Metall. 1984;18(3):265–8.

Allen MP, Tildesley DJ. Computer simulation of liquids. Oxford: Oxford Science Publications; 1987.

Haile JM. Molecular dynamics simulation: elementary methods. New York: Wiley; 1992.

Daw MS, Baskes MI. Semiempirical, quantum mechanical calculation of hydrogen embrittlement in metals. Phys Rev Lett. 1983;25(17):1285–8.

Daw MS, Baskes MI. Embedded-atom method: derivation and application to impurities, surfaces, and other defects in metals. Phys Rev B. 1984;29(12):6443–53.

Foiles SM, Baskes MI, Daw MS. Embedded-atom-method functions for the FCC metals Cu, Ag, Au, Ni, Pd, Pt, and their alloys. Phys Rev B. 1986;33(12):7983–91.

Ruda M, Farkas D, Abriata J. Embedded-atom interatomic potentials for hydrogen in metals and intermetallic alloys. Phys Rev B. 1996;54(14):9765–74.

Angelo JM, Moody NR, Baskes MI. Trap** of hydrogen to lattice defects in nickel. Model Simul Mater Sci Eng. 1995;3:289–307.

Baskes MI, Sha X, Angelo JM, Moody NR. Trap** of hydrogen to lattice defects in nickel. Model Simul Mater Sci Eng. 1997;5:651–2.

Lee B-J, Jang J-W. A modified embedded-atom method interatomic potential for the Fe-H system. Acta Mater. 2007;55:6779–88.

Baskes MI. Modified embedded-atom potentials for cubic materials and impurities. Phys Rev B. 1992;46(2):2727–42.

J. R. Shewchuk. An introduction to the conjugate gradient method without the agonizing pain. 1994. https://www.cs.cmu.edu/∼quake-papers/painless-conjugate-gradient.pdf

Anderson HC. Molecular dynamics simulations at constant pressure and/or temperature. J Chem Phys. 1980;72:2384–93.

Melchionna S, Ciccotti G, Holian BL, Hoover NPT. Dynamics for systems varying in shape and size. Mol Phys. 1993;78:533–44.

Hoagland RG, Heinisch HL. An atomistic simulation of the influence of hydrogen on the fracture behavior of nickel. J Mater Res. 1992;7(8):2080–8.

Hu Z, Fukuyama S, Yokogawa K, Okamoto S. Hydrogen embrittlement of a single crystal of iron on a nanometre scale at a crack tip by molecular dynamics. Model Simul Mater Sci Eng. 1999;7:541–51.

Xu X, Wen M, Hu Z, Fukuyama S, Yokogawa K. Atomistic process on hydrogen embrittlement of a single crystal of nickel by the embedded atom method. Comput Mater Sci. 2002;23:131–8.

Wen M, Xu X-J, Omura Y, Fukuyama S, Yokogawa K. Modeling of hydrogen embrittlement in single crystal Ni. Comput Mater Sci. 2004;30:202–11.

Solanki KN, Ward DN, Bammann DJ. A nanoscale study of dislocation nucleation at the crack tip in the nickel-hydrogen system. Metall Mater Trans A. 2011;42:340–7.

Song J, Curtin WA. Testing continuum concepts for hydrogen embrittlement in metals using atomistics. Model Simul Mater Sci Eng. 2010;18:045003.

Chandler MQ, Horstemeyer MF, Baskes MI, Wagner GJ, Gullett PM, Jelinek B. Hydrogen effects on nanovoid nucleation at nickel grain boundaries. Acta Mater. 2008;56:619–31.

Kuhr B, Farkas D, Robertson IM. Atomistic studies of hydrogen effects on grain boundary structure and deformation response in FCC Ni. Comput Mater Sci. 2016;122:92–101.

Song J, Curtin WA. A nanoscale mechanism for hydrogen embrittlement in metals. Acta Mater. 2011;59:1557–69.

Song J, Curtin WA. Atomic mechanism and prediction of hydrogen embrittlement in iron. Nat Mater. 2013;12(2):145–51.

Song J, Curtin WA. Mechanisms of hydrogen-enhanced localized plasticity: an atomistic study using α-Fe as a model system. Acta Mater. 2014;68:61–9.

Alvaro A, Thue Jensen I, Kheradmand N, Løvvik OM, Olden V. Hydrogen embrittlement in nickel, visited by first principles modeling, cohesive zone simulation and nanomechanical testing. Int J Hydrog Energy. 2015;40(47):16892–900.

Di Stefano D, Mrovec M, Elsässer C. First-principles investigation of hydrogen trap** and diffusion at grain boundaries in nickel. Acta Mater. 2015;98:306–12.

Sutton AP, Vitek V. On the structure of tilt grain boundaries in cubic metals I. Symmetrical tilt boundaries. Philos Trans R Soc A: Math Phys Eng Sci. 1983;309(1506):1–36.

O’Brien CJ, Foiles SM. Hydrogen segregation to inclined twin grain boundaries in nickel. Philos Mag. 2016;96(26):2808–28.

O’Brien CJ, Medlin DL, Foiles SM. Misoriented grain boundaries vicinal to the (111) 〈1 -1 0〉 twin in nickel Part I: thermodynamics & temperature-dependent structure. Philos Mag. 2016;96(13):1285–304.

Tsuzuki H, Branicio PS, Rino JP. Structural characterization of deformed crystals by analysis of common atomic neighborhood. Comput Phys Commun. 2007;177(6):518–23.

Faken D, Jónsson H. Systematic analysis of local atomic structure combined with 3D computer graphics. Comput Mater Sci. 1994;2(2):279–86.

Pedersen A, Jónsson H. Simulations of hydrogen diffusion at grain boundaries in aluminum. Acta Mater. 2009;57(14):4036–45.

Oudriss A, Creus J, Bouhattate J, Conforto E, Berziou C, Savall C, Feaugas X. Grain size and grain-boundary effects on diffusion and trap** of hydrogen in pure nickel. Acta Mater. 2012;60(19):6814–28.

Frenkel D, Smit B. Understanding molecular simulation. 2nd ed. Academic Press; London; 2002.

O’Brien CJ, Foiles SM. Misoriented grain boundaries vicinal to the (111) 〈1 -1 0〉 twin in nickel Part II: thermodynamics of hydrogen segregation. Philos Mag. 2016;96(14):1463–84.

Chandler MQ, Horstemeyer MF, Baskes MI, Gullett PM, Wagner GJ, Jelinek B. Hydrogen effects on nanovoid nucleation in face-centered cubic single-crystals. Acta Mater. 2008;56:95–104.

Foiles S. Calculation of the surface segregation of Ni-Cu alloys with the use of the embedded-atom method. Phys Rev B. 1985;32(12):7685–93.

Mishin Y, Cahn JW. Thermodynamics of Cottrell atmospheres tested by atomistic simulations. Acta Mater. 2016;117:197–206.

Von Pezold J, Lymperakis L, Neugebeauer J. Hydrogen-enhanced local plasticity at dilute bulk H concentrations: the role of H-H interactions and the formation of local hydrides. Acta Mater. 2011;59(8):2969–80.

Plimpton S. Fast parallel algorithms for short-range molecular dynamics. J Comput Phys. 1995;117(1):1–19.

Sadigh B, Erhart P, Stukowski A, Caro A, Martinez E, Zepeda-Ruiz L. Scalable parallel Monte Carlo algorithm for atomistic simulations of precipitation in alloys. Phys Rev B. 2012;85(18):184203.

Solanki KN, Tschopp MA, Bhatia MA, Rhodes NR. Atomistic investigation of the role of grain boundary structure on hydrogen segregation and embrittlement in α-Fe. Metall Mater Trans A. 2012;44(3):1365–75.

Vitek V, Wang GJ. Atomic structure of grain boundaries and intergranular segregation. J Phys Colloq. 1982;43(C6):147–61.

Cantwell PR, Tang M, Dillon SJ, Luo J, Rohrer GS, Harmer MP. Grain boundary complexions. Acta Mater. 2013;62(152):1–48.

Straumal B, Baretzky B. Grain boundary phase transitions and their influence on properties of polycrystals. Interface Sci. 2004;12(2–3):147–55.

Seita M, Hanson JP, Gradecak S, Demkowicz MJ. The dual role of coherent twin boundaries in hydrogen embrittlement. Nat Commun. 2015;6:6164.

Yamakov V, Saether E, Phillips DR, Glaessgen EH. Molecular-dynamics simulation-based cohesive zone representation of intergranular fracture processes in aluminum. J Mech Phys Solids. 2006;54:1899–928.

Yamakov V, Saether E, Glaessgen EH. Molecular modeling of intergranular fracture in aluminum: constitutive relation for interface debonding. J Mater Sci. 2008;43:7488–94.

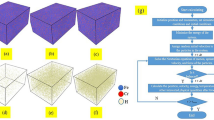

Barrows W, Dingreville R, Spearot D. Traction-separation relationships for hydrogen induced grain boundary embrittlement in nickel via molecular dynamics simulations. Mater Sci Eng A. 2016;650:354–64.

Dingreville R, Aksoy D, Spearot DE. A primer on selecting grain boundary sets for comparison of interfacial fracture properties in molecular dynamics simulations, Scientific Reports, 2017;7: 8332.

Adlakha I, Tschopp MA, Solanki KN. The role of grain boundary structure and crystal orientation on crack growth asymmetry in aluminum. Mater Sci Eng A. 2014;618:345–54.

Acknowledgments

This work is supported by the Laboratory Directed Research and Development Program at Sandia National Laboratories, a multi-mission laboratory managed and operated by Sandia Corporation, a wholly owned subsidiary of Lockheed Martin Corporation, for the US Department of Energy’s National Nuclear Security Administration under contract DE-AC0494AL85000.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this entry

Cite this entry

Spearot, D.E., Dingreville, R., O’Brien, C.J. (2019). Atomistic Simulation Techniques to Model Hydrogen Segregation and Hydrogen Embrittlement in Metallic Materials. In: Schmauder, S., Chen, CS., Chawla, K., Chawla, N., Chen, W., Kagawa, Y. (eds) Handbook of Mechanics of Materials. Springer, Singapore. https://doi.org/10.1007/978-981-10-6884-3_14

Download citation

DOI: https://doi.org/10.1007/978-981-10-6884-3_14

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-6883-6

Online ISBN: 978-981-10-6884-3

eBook Packages: EngineeringReference Module Computer Science and Engineering