Abstract

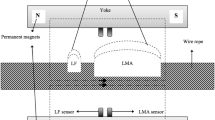

Flange joints refer to the most widespread detachable joints used in various industries. Such joints should be strong, durable, and leak proof. Compliance with these requirements depends largely on the uniformity of bolt tightening. In flange joints, it is necessary to provide that all bolts (pins) are tightened with equal force. Nonuniformity of bolt tightening could lead to different negative consequences, for example, to the lack of parts alignment, irregular gasket compression and as a result leaking of the product, misalignment of connected details, the origination of fastening details plastic deformations, and even breakage of bolts or pins. That is why controlling steel pins and bolts tightening force is very important for the provision of joint reliability and not only during assembly and installation of units and details of any other equipment but also during its operation. The present article is devoted to studying and testing of one of the modern and universal methods of bolt (pin) tightening force control—magnetic inspection based on structure-sensitive magnetic parameter control—remaining magnetic induction of the metal. The aim of present studies is to test the metal mechanical stress indicator IH-01m of a scanning type used at real facilities for measuring pin tightening force during operation.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Zagidullin TR (2015) The research and development of the method of local magnetic control of metal strain-stress state of package unit and metalwork elements. Dissertation, University of Ufa

Soloviev VL (2014) Assurance of machines reliability during their repair in agriculture by improving accuracy and uniformity of group threaded connections tightening. Dissertation, Omsk

Soloviev VL (2013) Improvement of accuracy and uniformity of group threaded connections tightening under operating conditions of different purpose equipment. In: Materials of the IV regional youth research-to-practice conference, Omsk

Blaer IL (2004) Thread tightening quality stabilization. Bull Mach Eng 9:20–22

Lipka VM (2010) Influence of structural and technological factors on reliability of threaded connections in mechanical engineering items. Bull SevNTU 110:198–201

Gusakov BV (2003) National and international methods and means of threaded connections calibrated tightening. Assembly Mach Eng, Instrum Eng 9:12–23

Shuvaev IV (2006) Efficiency improvement of threaded connections assembly and quality control by means of ultrasound application. Samara

Zhang X (2012) An improved torque method for preload control in precision assembly of miniature bolt joints. Strojniski Vestnik—J Mech Eng 58:578–586

Elizariev SV, Alyakritsky AL, Barat VA (2012) New portable instrument for non-destructive testing UNISCOPE. Int J NDT Territory 2:65–68

Zhitnikov YuZ, Vorkuev DS (2009) Justification of the method of assurance and quality control of group threaded connections tightening. Assembly Mach Eng, Instrum Eng 9:14–16

Khusainov ASh, Kuzmin YuA, Ovechkin AYu (2011) Control of bolt axial force and tightening torque in threaded connections during experimental research 1(151):65–68

Shulepov AP (2010) Determination of threaded connections tightening force control methods accuracy characteristics. Samara

Kuzeev IR (2006) Metal adaptive properties assessment by change of its magnetic parameters for determination of oil and gas equipment safe operation life. Oil Gas Eng 4:124–133

Samigullin AV (2014) Calculation-experimental determination of the limiting state of the shell structure material subject to low-cycle loading. Oil Gas Eng 5:404–419

Kuzeev IR, Naumkin EA, Tepsaev AN (2015) Generation of the response electromagnetic signal in the process of destruction of shell structures. SOCAR Proc 4:75–80

Bashirov MG, Kuzeev MI, Kuzeev IR (2004) Electromagnetic method of diagnosis in problems of operation safety assurance and evaluating the service life of equipment at petrochemical and petroleum-processing plants. Ind Saf 2:49–54

Dubov AA, Demin EA, Milyaev AI, Steklov OA (2002) Experience of gas pipeline stress-deformed state control by applying method of metal magnetic memory in comparison with traditional methods and stress control means. Control Diagn 4:53–56

Bobrov VT, Shevaldykin VG, Alekhin SG (2004) EMA transformation in pulsed magnetic field and its use in portable instruments for acoustic measure ments. In: 16th world conference on NDT, Montreal, 2004

Clossen M, Opheys M, Rauschenbach H, Frank S (2014) Validation of nonde structive examination methods for turbine field service. In: World conference on NDT, Prague, 6–10 Oct 2014

Deng D, Wu X (2014) Principle of the steel cable tension measurement based on spatial magnetic field distributions. In: World conference on NDT, Prague, 6–10 Oct 2014

Joh C, Lee JW, Kwahk I (2013) Feasibility study of stress measurement in prestressing tendons using villari effect and induced magnetic field. Int J Distrib Sens Netw

Krylov YuV (1987) Mechanical work and bench-work and assembly. Lenizdat

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this paper

Cite this paper

Tukaeva, R.B., Prokhorov, A.A., Miniakhmetov, O.Y. (2019). Magnetic Inspection for Assessing the Uniformity of Flange Joints Bolt Tightening. In: Radionov, A., Kravchenko, O., Guzeev, V., Rozhdestvenskiy, Y. (eds) Proceedings of the 4th International Conference on Industrial Engineering. ICIE 2018. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-319-95630-5_191

Download citation

DOI: https://doi.org/10.1007/978-3-319-95630-5_191

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-95629-9

Online ISBN: 978-3-319-95630-5

eBook Packages: EngineeringEngineering (R0)