Abstract

The possibility to shape glass easily and in all kind of forms for applications in our everyday life is one of the key factors to its success. The fabrication of a glass article comprises a succession of steps, often starting from a hot glass melt that is shaped during its cooling. The product can then be worked at lower temperatures, to modify its dimensions or its surface finish.

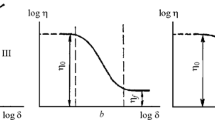

In this chapter, the sha** processes at both high and low temperatures are presented. In a first part, the different forming processes (sha** at high temperature) developed by the glass industry are illustrated, and a specific emphasis is given to glass viscosity, a key parameter in these processes. In the second part of the chapter, the sha** processes occurring at low temperatures, such as cutting or grinding, are described. In this section, specific attention is given to the mechanical behavior of the glass during the process as well as to machining parameters.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

W. Trier, K.L. Loewenstein: Glass Furnaces: Design, Construction and Operation (Society of Glass Technology, Sheffield 1987)

E.B. Shand, C.H. Greene, J.A. Grant: Glass Engineering Handbook (McGraw-Hill, New York 1958)

S.R. Scholes, C.H. Greene: Modern Glass Practice, 7th edn. (Cahners, Boston 1975)

E.L. Bourhis: Glass—Mechanics and Technology (Wiley, Weinheim 2008)

I.W. Donald: Glass-To-Metal Seals (Society of Glass Technology, Sheffield 2009)

A. Fluegel: Glass viscosity calculation based on a global statistical modelling approach, Glass Technol. 48(1), 13–30 (2007)

ASTM C338-93: Standard Test Method for Softening Point of Glass (ASTM International, West Conshohocken 2008)

G. Chui: Heat transfer and temperature control in an annealing lehr for float glass, J. Am. Ceram. Soc. 60(11/12), 477–484 (1977)

M. Cable: Mechanization of glass manufacture, J. Am. Ceram. Soc. 82(5), 1095–1112 (1999)

A. Warude: Analysis of Glass Mold to Enhance Rate of Heat Transfer, M.Sc. Thesis (Univ. South Florida, Tampa 2004)

X.H. Zhang, Y. Guimond, Y. Bellec: Production of complex chalcogenide glass optics by molding for thermal imaging, J. Non-Cryst. Solids 326/327, 519–523 (2003)

F.T. Wallenberger, J.C. Watson, H. Li: Glass fibers. In: ASM Handbook Composites, Vol. 21, ed. by D.B. Miracle, S.L. Donaldson (ASM International, Materials Park 2001) pp. 27–34

A.K. Varshney: Chemical strengthening of glass: Lessons learned and yet to be learned, Int. J. Appl. Glass. Sci. 1(2), 131–142 (2010)

H.J. Stevens: Engineered Materials Handbook: Ceramics and Glasses, Vol. 4 (ASM International, Materials Park 1991), ed. by S.J. Schneider

L.A.B. Pilkington, K. Bickerstaff: Improvements in or relating to the manufacture of glass, GB Patent 769692 (1954)

L.A.B. Pilkington, K. Bickerstaff: Manufacture of flat glass, US Patent 2911759 (1959)

M. Cable: The development of flat glass manufacturing process, Transact. Newcomen Soc. 74, 19–43 (2004)

B. Scholz, F.S. Kirn: Early Nineteenth Century Glass Technology in Austria and Germany (Society of Glass Technology, Sheffield 2004), translated by M. Cable

M.L.F. Nascimento: Brief history of the flat glass patent—Sixty years of the float process, World Patent Inf. 38, 50–56 (2014)

N. Ban, T. Kamihori, H. Takamuku: A study of the behavior of volatiles in the float process, J. Non-Cryst. Solids 345/346, 777–781 (2004)

J. Belis, B. Inghelbrecht, R.V. Impe, D. Callewaert: Cold bending of laminated glass panels, Heron 52(1/2), 123–146 (2007)

S.M. Dockerty: Sheet forming apparatus, US Patent 3338696A (1967)

S.M. Dockerty, G.C. Shay: Downflow sheet drawing method and apparatus, US Patent 3149949A (1964)

H.J. Lin, W.K. Chang: Design of a sheet forming apparatus for overflow fusion process by numerical simulation, J. Non-Cryst. Solids 353, 2817–2825 (2007)

G. Delaizir, L. Calvez: A novel approach to develop chalcogenide glasses and glass-ceramics by pulsed current electrical sintering (PCES). In: Sintering of Ceramics—New Emerging Techniques, ed. by A. Lakshmanan (InTechOpen, London 2012) pp. 281–306

W.D. Kingery, H.K. Bowen, D.R. Uhlmann: Introduction to Ceramics (Wiley, Chichester 1976)

M. Hubert, G. Delaizir, J. Monnier, C. Godart, H.-L. Ma, X.-H. Zhang, L. Calvez: An innovative approach to develop highly performant chalcogenide glasses and glass-ceramics transparent in the infrared range, Opt. Express 19(23), 23513–23522 (2011)

J. Jones, A. Clare (Eds.): Bioglasses—An Introduction (Wiley, Chichester 2012)

R. Gmeiner, U. Deisinger, J. Schonherr, B. Lechner, R. Detsch, A. Boccaccini, J. Stampfl: Additive manufacturing of bioactive glasses and silicate bioceramics, J. Ceram. Sci. Technol. 6(2), 75–86 (2015)

J. Klein: Additive Manufacturing of Optically Transparent Glass, M.Sc. Thesis (MIT, Boston 2015)

J. Klein, G. Franchin, M. Stern, M. Kayser, C. Inamura, S.Dave, N. Oxman, P. Houk: Methods ands apparatus for additive manufacturing of glass, US patent application 20150307385 (2015)

J. Klein, M. Stern, G. Franchin, M. Kayser, C. Inamura, S. Dave, J.C. Weaver, P. Houk, P. Colombo, M. Yang, N. Oxman: Additive manufacturing of optically transparent glass, 3-D Print. Addit. Manuf. 2(3), 92–105 (2015)

A. Brient, M. Brissot, T. Rouxel, J.C. Sangleboeuf: Influence of grinding parameters on glass workpieces surface finish using response surface methodology, J. Manuf. Sci. Eng. 133(4), 044501–044501 (2011)

A. Brient, R. Laniel, M. Miroir, G.L. Goic, J.C. Sangleboeuf, S. Samper: Multiscale topography analysis of water-jet pocketing of silica glass surfaces. In: Proc. 15th Int. Conf. Metrol. Prop. Eng. Surf., Charlotte (2015)

R. Laniel, M. Tchikou, J.-C. Sangleboeuf: A discrete elements simulation and analysis of a high energy stirred milling process, Mech. Ind. 13, 415–421 (2012)

A. Arora, D.B. Marshall, B.R. Lawn, M.V. Swain: Indentation deformation/fracture of normal and anomalous glasses, J. Non-Cryst. Solids 31(3), 415–428 (1979)

R.F. Cook, G.M. Pharr: Direct observation and analysis of indentation cracking in glasses and ceramics, J. Am. Ceram. Soc. 73(4), 787–817 (1990)

I. Finnie: Some reflections on the past and future of erosion, Wear 186, 1–10 (1995)

M. Hashish: A modeling study of metal cutting with abrasive water-jets, J. Eng. Mater. Technol. 106(1), 88–100 (1984)

J.G.A. Bitter: A study of erosion phenomena part I, Wear 6(1), 5–21 (1963)

J.G.A. Bitter: A study of erosion phenomena, Wear 6(3), 169–190 (1963)

J.H. Neilson, A. Gilchrist: Erosion by a stream of solid particles, Wear 11(2), 111–122 (1968)

V. Le Houérou: Scratchability of Soda-Lime Silica Glasses, Ph.D. Thesis (Universite de Rennes, Rennes 2005)

V. Le Houérou, J.C. Sangleboeuf, S. Deriano, T. Rouxel, G. Duisit: Surface damage of soda–lime–silica glasses: indentation scratch behavior, J. Non-Cryst. Solids 316(1), 54–63 (2003)

T. Yu, H. Li, W. Wang: Experimental investigation on grinding characteristics of optical glass BK7: With special emphasis on the effects of machining parameters, Int. J. Adv. Manuf. Technol. 82(5), 1405–1419 (2016)

R.L. Hecker, I.M. Ramoneda, S.Y. Liang: Analysis of wheel topography and grit force for grinding process modeling, J. Manuf. Process. 5(1), 13–23 (2003)

M. Barge, J. Rech, H. Hamdi, J.-M. Bergheau: Experimental study of abrasive process, Wear 264(5/6), 382–388 (2008)

P. Stępień: A probabilistic model of the grinding process, Appl. Math. Model. 33(10), 3863–3884 (2009)

H.-C. Chang, J.J.J. Wang: A stochastic grinding force model considering random grit distribution, Int. J. Mach. Tools Manuf. 48(12/13), 1335–1344 (2008)

M. Bigerelle, D. Najjar, A. Iost: Multiscale functional analysis of wear: A fractal model of the grinding process, Wear 258(1–4), 232–239 (2005)

G.T. Smith: Industrial Metrology: Surfaces and Roundness (Springer, London 2002)

D.J. Whitehouse: Handbook of Surface Metrology (CRC, Boca Raton 1994)

T. Suratwala, L. Wong, P. Miller, M.D. Feit, J. Menapace, R. Steele, P. Davis, D. Walmer: Sub-surface mechanical damage distributions during grinding of fused silica, J. Non-Cryst. Solids 352(52–54), 5601–5617 (2006)

R. Laheurte, P. Darnis, N. Darbois, O. Cahuc, J. Neauport: Subsurface damage distribution characterization of ground surfaces using Abbott–Firestone curves, Opt. Express 20(12), 13551–13559 (2012)

D.A. Stephenson, J.S. Agapiou: Metal Cutting Theory and Practice, 3rd edn. (CRC, Boca Raton 1994)

H. Demir, A. Gullu, I. Ciftci, U. Seker: An investigation into the influences of grain size and grinding parameters on surface roughness and grinding forces when grinding, Strojniski Vestnik/J. Mech. Eng. 56(7/8), 447–454 (2010)

S. Tong, S.M. Gracewski, P.D. Funkenbusch: Measurement of the preston coefficient of resin and bronze bond tools for deterministic microgrinding of glass, Precis. Eng. 30(2), 115–122 (2006)

R.L. Hecker, S.Y. Liang: Predictive modeling of surface roughness in grinding, Int. J. Mach. Tools Manuf. 43(8), 755–761 (2003)

Y. Zhang, Y. Luo, J.F. Wang, Z. Li: Research on the fractal of surface topography of grinding, Int. J. Mach. Tools Manuf. 41(13/14), 2045–2049 (2001)

G. Savio, R. Meneghello, G. Concheri: A surface roughness predictive model in deterministic polishing of ground glass moulds, Int. J. Mach. Tools Manuf. 49(1), 1–7 (2009)

A. Venu Gopal, P. Venkateswara Rao: Selection of optimum conditions for maximum material removal rate with surface finish and damage as constraints in SiC grinding, Int. J. Mach. Tools Manuf. 43(13), 1327–1336 (2003)

J.-S. Kwak: Application of Taguchi and response surface methodologies for geometric error in surface grinding process, Int. J. Mach. Tools Manuf. 45(3), 327–334 (2005)

W. Gu, Z. Yao, H. Li: Investigation of grinding modes in horizontal surface grinding of optical glass BK7, J. Mater. Process. Technol. 211(10), 1629–1636 (2001)

M.C. Shaw: Principles of Abrasive Processing (Clarendon, Oxford 1996)

T.G. Bifano, T.A. Dow, R.O. Scattergood: Ductile-regime grinding: A new technology for machining brittle materials, J. Eng. Ind. 113(2), 184–189 (1991)

S. Ferrendier: Influence de l'Evolution Granulométrique des Abrasifs sur l'Enlèvement de Matière lors de la Découpe par Jet d'Eau Abrasif, Ph.D. Thesis (École Nationale Supérieure d'Arts et Métiers, Paris 2001)

L. Vignaret: Découpage au jet de fluide, Oxycoupage, jet de plasma, laser et jet d'eau sous pression. In: Techniques de l'ingénieur (1989) B7340 v1

A. Comier: Développement d'un modèle d'enlèvement de matière par granulation utilisant le jet d'eau haute pression: Application au démantèlement de pneumatiques, Ph.D. Thesis (École Nationale Supérieure d'Arts et Métiers, Paris 2004)

G. Fowler: Abrasive Water-Jet Controlled Depth Milling of Titanium Alloys, Ph.D. Thesis (University of Nottingham, Nottingham 2003)

A.A. El-Domiaty, M.A. Shabara, A.A. Abdel-Rahman, A.K. Al-Sabeeh: On the modelling of abrasive water-jet cutting, Int. J. Adv. Manuf. Technol. 12(4), 255–265 (1996)

S. Hloch, J. Valíček: Topographical anomaly on surfaces created by abrasive water-jet, Int. J. Adv. Manuf. Technol. 59(5), 593–604 (2012)

S. Hloch, J. Valíček: Abrasive water-jet cutting mechanism, Strojarstvo 10, 12–13 (2006)

M. Chithirai Pon Selvan, N. Mohana Sundara Raju: Assessment of process parameters in abrasive water-jet cutting of stainless steel, Int. J. Adv. Eng. Technol. 1(3), 34–40 (2011)

M. Hashish: Optimization factors in abrasive-water-jet machining, J. Eng. Ind. 113(1), 29–37 (1991)

M. Chithirai Pon Selvan, N. Mohana Sundara Raju: Abrasive water-jet cutting surfaces of ceramics—An experimental investigation, Int. J. Adv. Sci. Eng. Technol. Res. 1(3), 52–59 (2012)

A. Laurinat, H. Louis, G. Meier-Wiechert: A model for milling with abrasive water-jet. In: Proc. 7th Am. Water-Jet Conf., Water Jet Tech. Assoc., Saint Louis (1993)

G. Fowler, I.R. Pashby, P.H. Shipway: The effect of particle hardness and shape when abrasive water jet milling titanium alloy Ti6Al4V, Wear 266(7/8), 613–620 (2009)

G. Fowler, P.H. Shipway, I.R. Pashby: Abrasive water-jet controlled depth milling of Ti6Al4V alloy—An investigation of the role of jet–work piece traverse speed and abrasive grit size on the characteristics of the milled material, J. Mater. Process. Technol. 161(3), 407–414 (2005)

Y. Petit: Découpe du verre plat de silicate sodocalcique. In: Techniques de l'ingénieur Sciences et technologies du verre (2012) n4401

A.A. Khan, M.M. Haque: Performance of different abrasive materials during abrasive water jet machining of glass, J. Mater. Proc. Technol. 191(1–3), 404–407 (2007)

L.M. Hlaváč, I.M. Hlaváčová, L. Gembalová, J. Kaličinský, S. Fabian, J. Měšt'ánek, J. Kmec, V. Mádr: Experimental method for the investigation of the abrasive water jet cutting quality, J. Mater. Process. Technol. 209(20), 6190–6195 (2009)

M.C. Kong, D. Axinte, W. Voice: An innovative method to perform maskless plain water-jet milling for pocket generation: A case study in Ti-based superalloys, Int. J. Mach. Tools Manuf. 51(7/8), 642–648 (2011)

J. Wang: Abrasive water-jet machining of polymer matrix composites–cutting performance, erosive process and predictive models, Int. J. Adv. Manuf. Technol. 15(10), 757–768 (1999)

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Laniel, R., Hubert, M., Miroir, M., Brient, A. (2019). Glass Sha**. In: Musgraves, J.D., Hu, J., Calvez, L. (eds) Springer Handbook of Glass. Springer Handbooks. Springer, Cham. https://doi.org/10.1007/978-3-319-93728-1_36

Download citation

DOI: https://doi.org/10.1007/978-3-319-93728-1_36

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-93726-7

Online ISBN: 978-3-319-93728-1

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)