Abstract

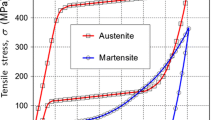

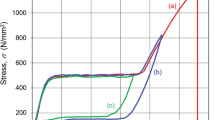

A shape memory alloy (SMA) is expected to be applied as intelligent or smart material since it shows the functional characteristics of the shape memory effect and superelasticity. Most SMA elements, with these characteristics, perform cyclic motions. In these cases, the fatigue property of SMA is one of the most important subjects in view of evaluating functional characteristics of SMA elements. The fatigue properties are complex since they depend on stress, strain, temperature and their hysteresis. If SMA is implanted by high energy ions, the thermomechanical properties of the material may change, resulting in long fatigue life. If the ultrasonically activated shot peening is applied to SMA, the compressive residual stress may be produced, resulting in an increase in fatigue performance. In the present study, the tensile deformation and bending fatigue properties of a superelastic thin wire, a highelastic thin wire, and a superelastic tape, all made of TiNi alloys, were investigated experimentally. In order to improve the fatigue properties, the nitrogen ion implantation and the ultrasonic shot peening were applied to modify the surface layer of the TiNi SMA tape and the influence of implantation and shot peening treatments on the bending fatigue properties was investigated.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Asaoka T, Mitsuo M (2000) Effect of aluminum ion implantation on shape memory properties of titanium-nickel alloy. Mater Trans JIM 41(6):739–744

Cheong SK, Lee DS, Lee JH, Handa M, Watanabe Y (2008) Effect of ultrasonic shot peening on the fatigue characteristics of welded STS304 for rolling stock. In: Proceedings of ICSP-10, Tokyo, Japan

Duerig TW, Melton KN, Stockel D, Wayman CM (eds) (1990) Engineering aspects of shape memory alloy. Butterworth-Heinemann

Funakubo H (ed) (1987) Shape memory alloys. Gordon and Breach Science Publishers

Furukawa Catalogue (2000) No. 2E-GISI-00-21

He YJ, Sun QP (2011) On non-monotonic rate dependence of stress hysteresis of superelastic shape memory alloy bars. Int J Solids Struct 48:1688–1695

Hirvonen JK (1980) Ion implantation. Academic Press, United States

Holtz RL, Sadananda K, Imam MA (1999) Fatigue thresholds of Ti-Ni alloy near the shape memory transition temperature. Int J Fatigue 21:137–145

Ivasishin OM, Pogrebnjak AD, Bratushka SN (2011) Nanostructural layers and coating formed by ion-plasma fluxes in titanium alloys and steels. Kyiv, Akademperiodyla, p 284

Kyriakides, S (2001) Propagating instabilities in materials, materials science for the 21st century. A. Soc. Mater. Science, Japan, pp 316–325

Matsui R, Tobushi H, Furuichi Y, Horikawa H (2004) Tensile deformation and rotating-bending fatigue properties of a highelastic thin wire, a superelastic thin wire, and a superelastic thin tube of NiTi alloys. Trans ASME J Eng Mater Technol 126:384–391

McKelvey AL, Ritchie RO (2001) Fatigue-crack growth behavior in the superelastic and shape-memory alloy nitinol. Metall Mater Trans A 32A:731–743

Miyazaki S, Otsuka K, Suzuki Y (1981) Pseudoelasticity and deformation behavior in a Ti-50.6at%Ni alloy. Scr Mater 15:287–292

Otsuka K, Wayman CM (eds) (1998) Shape memory materials. Cambridge University Press

Peletier H, Muller D, Mille P, Grob J (2002) Structural and mechanical characterization of born nad nitrogen implanted NiTi shape memory alloy. Surf Coat Technol 158(159):309–317

Pogrebnjak AD, Bazyl EA (2001) Modification of wear and fatigue characteristics of Ti-V-Al alloy by Cu and Ni ion implantation and high-current electron beam treatment. Vacuum 64(1):1–7

Shaw JA, Kyriakides S (1995) Thermomechanical aspects of NiTi. J Mech Phys Solids 43(8):1243–1281

Takeda K, Matsui R, Tobushi H, Homma S, Hattori K (2015a) Enhancement of fatigue life in TiNi shape memory alloy by ultrasonic shot peening. Mater Trans 56(4):513–518

Takeda K, Matsui R, Tobushi H, Homma S, Levintant-Zayonts N, Kucharski S (2015b) Enhancement of bending fatigue life TiNi shape-memory alloy tape by nitrogen ion implantation. Arch Mech 67(4):293–310

Takeda K, Mitsui K, Tobushi H, Levintant-Zayonts N, Kucharski S (2013) Influence of nitrogen ion implantation on deformation and fatigue properties of TiNi shape memory alloy wire. Arch Mech 65(5):391–405

Tanaka K, Kobayashi S, Sato Y (1986) Thermomechanics of transformation pseudoelasticity and shape memory effect in alloys. Int J Plast 2:59–72

Tobushi H, Matsui R, Takeda K, Pieczyska EA (2013) Mechanical properties of shape memory materials, Part 2. Fatigue properties of shape memory alloy. Nova Science Publishers, New York, pp 115–164

Tobushi H, Takata K, Shimeno Y, Nowacki WK, Gadaj SP (1999) Influence of strain rate on superelastic behaviour of TiNi shape memory alloy. Proc Inst Mech Eng 213(Part L):93–102

Wagner L (ed) (2003) Shot peening, 1-562. Wiley-VCH, Weinheim

Wagner M, Sawaguchi T, Kaustrater G, Hoffken D, Eggeler G (2004) Structural fatigue of pseudoelastic NiTi shape memory wires. Mater Sci Eng A 378:105–109

Yin H, He YJ, Moumni Z, Sun QP (2016) Effects of grain size on tensile fatigue life of nanostructured NiTi shape memory alloy. Int J Fatigue 88:166–177

Acknowledgements

The experimental work for this study was carried out with the assistance of students in Aichi Institute of Technology, to whom the authors wish to express their gratitude. The authors also wish to extend thanks to the administrators of Scientific Research (C) (General) in Grants-in-Aid for Scientific Research by the Japan Society for Promotion of Science for financial support.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this chapter

Cite this chapter

Matsui, R., Takeda, K., Tobushi, H. (2017). Fatigue Property and Enhancement of Fatigue Life of TiNi Shape Memory Alloys—An Over View. In: Sun, Q., Matsui, R., Takeda, K., Pieczyska, E. (eds) Advances in Shape Memory Materials. Advanced Structured Materials, vol 73. Springer, Cham. https://doi.org/10.1007/978-3-319-53306-3_9

Download citation

DOI: https://doi.org/10.1007/978-3-319-53306-3_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-53305-6

Online ISBN: 978-3-319-53306-3

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)