Abstract

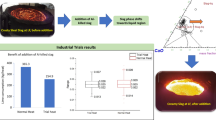

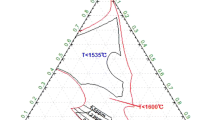

The spring steel 55SiCrA produced in a domestic steel factory is deoxidized by Si with “100 t EAF-LF-VD-CC”. The fluoric content (CaF2 = 17.41–22.15%) and the binary basicity (R = 1.9–3.0) of applied LF refining slag are high. To avoid environmental pollution caused by fluorine, meanwhile guarantee the speed of melting slag and smelting effect on molten steel, the structure of refining slag was adjusted. A new fluorine-free slag system was obtained by changing slagging process, adjusting adding amounts of slag-making materials, such as lime, calcium carbide, silicon carbide and so on. This new fluorine-free slag was applied in industrial tests. The results showed that this new fluorine-free slag could meet smelting demands well. The average mass fraction of oxygen content of spring steel 55SiCrA billets could decreased from 11 × 10−6 to 9 × 10−6 and the plasticity of inclusions also changed better. All compositions of observed inclusion in billets were within the 1400 °C liquidus in Al2O3-SiO2-CaO-MgO-MnO phase diagram.

Similar content being viewed by others

References

Zhao, D. W., et al. (2013). Composition optimization of LF refining slag in high cleanliness Al-killed steel. Steelmaking, 29(2), 9–13.

Ma, W. J., et al. (2014). Influence of slag composition on bearing steel cleanness. Ironmaking and Steelmaking, 41(1), 26–30.

Oshiro, T., et al. (1989). Verbesserung der dauerhalt-barkeit von ventilfederdraht. Stahl und Eisen, 21(10), 1011–1015.

Suito, H., & Inoue, R. (1996). Thermodynamics on control of inclusions composition in ultraclean steels. ISIJ International, 36(5), 528–536.

Onoe, T., et al. (1987). Shape control of inclusions for steel tire cord (development in ladle arc refining). Transactions of ISIJ, 27, B249.

Ge, Y. Z., et al. (2013). Best composition of CaO-Al2O3 slag system for refining of 20CrMnTiH steel. Iron and Steel, 48(10), 23–27.

Wu, C., et al. (2013). Effect of refining slag with different basicities on inclusions in spring steel. Journal of Wuhan University of Science and Technology, 36(4), 254–257.

Jiang, M., et al. (2010). Laboratory study on evolution mechanisms of non-metallic inclusions in high strength alloyed steel refined by high basicity slag. ISIJ International, 50(1), 95–104.

Reis, B. H., Bielefeldt, W. V., & Vilela, A. C. F. (2014). Efficiency of inclusion absorption by slags during secondary refining of steel. ISIJ International, 54(7), 1584–1591.

Liu, F. Y., Xu, Z. G., & Shang, M. (2013). A study on 80 t converter-ladle furnace refining slag for high quality GCr15 bearing steel steelmaking. Special Steel, 34(1), 25–27.

Yan, P. C., et al. (2013). Effect of the CaO-Al2O3-Based top slag on the cleanliness of stainless steel during secondary metallurgy. Metallurgical and Materials transactions B, 44B(10), 1105–1119.

Deng, Z. Y., et al. (2013). Effect of basicity on deoxidation capability of refining slag. Journal of Iron and Steel Research International, 20(2), 21–26.

Chen, S. H., et al. (2013). Industrial application of desulfurization using low basicity refining slag in tire cord steel. Journal of Iron and Steel Research International, 20(1), 26–33.

Acknowledgements

This research was supported financially by the National Natural Science Foundation of China (No. 51404022) and State Key Laboratory of Advanced Metallurgy Foundation (No. 41614014).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Gu, C., Bao, Yp., Lin, L., Wang, M., Zhao, Lh., Wu, Zx. (2017). Study on Adjustment and Optimization of LF Refining Slag of Spring Steel 55SiCrA. In: Meyers, M., et al. Proceedings of the 3rd Pan American Materials Congress. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-52132-9_77

Download citation

DOI: https://doi.org/10.1007/978-3-319-52132-9_77

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-52131-2

Online ISBN: 978-3-319-52132-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)