Abstract

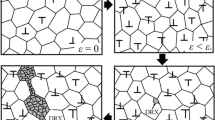

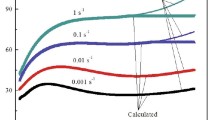

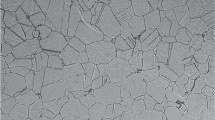

A new model to predict the dislocation density evolution of 30Cr2Ni4MoV steel during hot deformation was proposed in this study. Hot compression of 30Cr2Ni4MoV steel was carried out on Gleeble 1500 at different temperatures and strain rates. A series of flow curves was obtained and the experimental dislocation density evolution was derived from the experimental flow curves. Based on the obtained flow curves, the dependences of yield stress, critical stress and strain of dynamic recrystallization and the saturation stress on temperature and strain rate were determined. Two sets of dislocation density equation were derived from the experimental flow curves: (I) a dislocation density relation describing the grains in which dynamic recovery took place only; and (II) an average dislocation density expression pertaining to the recrystallized grains. All the parameters needed for the determination of the dislocation equations were calculated and expressed as a function of strain, temperature and strain rate. A physically realistic and practical kinetics model of dynamic recrystallization was determined with the aid of the above relations. Finally, the dependence of the dislocation density on strain, deformation temperature and strain rate was determined and the predicted results agreed well with the experimental results.

Similar content being viewed by others

References

Tsuzaki, K., Huang, X. X., & Maki, T. (1996). Mechanism of dynamic continuous recrystallization during superplastic deformation in a microduplex stainless steel. Acta Mateialia, 44, 4491–4499.

Gourdet, S., & Montheillet, F. (2000). An experimental study of the recrystallization mechanism during hot deformation of aluminium. Materials Science and Engineering A, 283, 274–288.

Sakai, T. (1995). Dynamic recrystallization microstructures under hot working conditions. Journal of Materials Processing Technology, 53, 349–361.

Belyakov, A., Miura, H., & Sakai, T. (1998). Dynamic recrystallization under warm deformation of a 304 type austenitic stainless steel. Materials Science and Engineering A, 255, 139–147.

Sakai, T., Belyakov, A., Kaibyshev, R., Miura, H., & Jonas, J. J. (2014). Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Progress in Materials Science, 60, 130–207.

Doherty, R. D., Hughes, D. A., Humphreys, F. J., Jonas, J. J., Juul Jensen, D., Kassner, M. E., et al. (1997). Current issues in recrystallization: A review. Materials Science and Engineering A, 238, 219–274.

Mecking, H., & Kocks, U. F. (1981). Kinetics of flow and strain-hardening. Acta Metallurgica, 29, 1865–1875.

Estrin, Y., & Necking, H. (1984). A unified phenomenological description of work hardening and creep based on one-parameter models. Acta Metallurgica, 32, 57–70.

Jonas, J. J., Quelennec, X., Jiang, L., & Martin, E. (2009). The Avrami kinetics of dynamic recrystallization. Acta Materialia, 57, 2748–2756.

Quelennec, X., Bozzolo, N., Jonas, J. J., & Logé, R. (2011). A new approach to modeling the flow curve of hot deformed austenite. ISIJ International, 51, 945–950.

Seki, I., & Nagata, K. (2005). Supersaturation of carbon in austenite during carburization by CO gas. ISIJ International, 45, 1536–1542.

Ghosh, G., & Olson, G. B. (2002). The isotropic shear modulus of multicomponent Fe-base solid solutions. Acta Materialia, 50, 2655–2675.

Poliak, E. I., & Jonas, J. J. (1996). A one-parameter approach to determining the critical conditions for the initiation of dynamic recrystallization. Acta Materialia, 44, 127–136.

Poliak, E. I., & Jonas, J. J. (2003). Critical strain for dynamic recrystallization in variable strain rate hot deformation. ISIJ International, 43, 692–700.

Poliak, E. I., & Jonas, J. J. (2003). The critical strain for dynamic recrystallization in rolling mills. Materials Science Forum, 426, 57–66.

Quelennec, X., & Joseph, J. J. (2012). Simulation of austenite flow curves under industrial rolling conditions using a physical dynamic recrystallization model. ISIJ International, 52, 1145–1152.

Chen, F., Cui, Z. S., & Chen, S. J. (2011). Recrystallization of 30Cr2Ni4MoV ultra-super-critical rotor steel during hot deformation. Part I: Dynamic recrystallization. Materials Science and Engineering A, 528, 5073–5080.

Acknowledgements

The authors gratefully acknowledge financial support from National Basic Research Program of China (2011CB012903).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Zhou, P., Ma, Q. (2017). Evolution of Austenite Dislocation Density During Hot Deformation Using a Physical Dynamic Recrystallization Model. In: Meyers, M., et al. Proceedings of the 3rd Pan American Materials Congress. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-52132-9_71

Download citation

DOI: https://doi.org/10.1007/978-3-319-52132-9_71

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-52131-2

Online ISBN: 978-3-319-52132-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)