Abstract

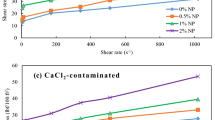

One of the main damage mechanisms identified in the Ocelote field is the drilling-induced formation damage during drilling operations. The productivity of a well during its production life decreases because of fines migration and changes in the wettability due to organic deposits. In this study, we designed a double purpose nanofluid to reduce the drilling-induced formation damage while the invaded mud filtrate enhances the mobility of the crude oil and migration fines control. The nanoparticles (NPs) used were fumed silica and commercial alumina. The effectiveness of the nanoparticles in improving the rheological and filtration properties of the drilling fluid was assessed by conducting rheological and filtration tests under high pressure–high temperature (HPHT) conditions in terms of the NP concentration after the hot rolling process. The experimental results in terms of the plastic viscosity, yield point, and gel strength showed that as the NP concentration increases, the values of the rheological parameters increase, with the Si NPs exhibiting the best performance. Regarding the filtration properties, the Si and Al NPs reduced the filtration volume by 17%, with the Si nanoparticles presenting the highest reduction in the mudcake thickness of 6%. At NP concentrations above 0.3 wt.%, the filtration reduction effect decreases. Therefore, the mud filtrate obtained from the HPHT filtration test conducted on a drilling fluid with an NP concentration of 0.05 wt.% was used to evaluate the mud filtrate quality to improve the mobility of the crude oil by interfacial tension (IFT) reduction and the capacity to alter the oil-wet to water-wet surface. The retention of the fine particles in impregnated Ottawa sand was tested through a break–rupture curve. The results showed that the mud filtrate with Al NPs could decrease the IFT between the intermediate heavy crude (23°API) and the mud filtrate by more than 24% and could alter the contact angle from approximately 66 to 41 °C. Additionally, the core treated with the mud filtrate with Al NPs imbibed twice the mass in 2 h, more than the core treated with the mud filtrate in the absence of NPs. Hence, the Si NPs did not present significant changes in the IFT and wettability alteration but increased the retention of the fine particles in the treated sand. The Al NPs helped reduce the filtration volume, presented a marked impact on the wettability alteration to preferential water-wet, reduced the IFT, and to some extent aided fines migration control; therefore, the Al NPs were selected for the evaluation in displacement tests on rock samples under dynamic and reservoir conditions. Additionally, the drilling fluid with the Al NPs reduced the dynamic filtration volume by 45% with a subsequent reduction in the formation damage by 20% and increase in the critical flow of migratory clays by 66% in comparison with the drilling fluid without NPs. Finally, the residual water saturation was reduced, and the crossover point between the relative permeability curves shifted to the right. Finally, technical studies for field applications will be carried out, where two twin wells with similar properties will be drilled, allowing for a comparative analysis of the application of NPs to drilling fluids with the same formulation in terms of the invasion diameter, well stabilization time, productivity index, and solid production.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

B. Peng, S. Peng, B. Long, Y. Miao, W.Y. Guo, Properties of high-temperature-resistant drilling fluids incorporating acrylamide/(acrylic acid)/(2-acrylamido-2-methyl-1-propane sulfonic acid) terpolymer and aluminum citrate as filtration control agents. J. Vinyl Addit. Technol. 16, 84–89 (2010)

M. Aston, P. Mihalik, J. Tunbridge, S. Clarke, Towards zero fluid loss oil based muds, in SPE Annual Technical Conference and Exhibition (2002)

D. Jiao, M.M. Sharma, Dynamic filtration of invert-emulsion muds. SPE Drill. Complet. 8, 165–169 (1993)

S. Gharat, J. Azar, D. Teeters, Effect of incompatibilities caused by fluids filtrates on formation properties, in SPE Formation Damage Control Symposium (1994)

D.B. Bennion, R.F. Bietz, F.B. Thomas, M.P. Cimolai, Reductions in the productivity of oil and low permeability gas reservoirs due to aqueous phase trap**. J. Can. Pet. Technol. 33, 45–54 (1994)

D. Jia, J. Buckley, and N. Morrow, Alteration of wettability by drilling mud filtrates, in SCA Symposium, Norway, September (1994)

G. Phelps, G. Stewart, J. Peden, The effect of filtrate invasion and formation wettability on repeat formation tester measurements, in European Petroleum Conference (1984)

A. Wojtanowicz, Z. Krilov, J. Langlinais, Experimental determination of formation damage pore blocking mechanisms. J. Energy Resour. Technol. 110, 34–42 (1988)

R. Caenn, H. Darley, G. Gray, Chapter 10—Completion, reservoir drilling, workover, and packer fluids, in Composition and Properties of Drilling and Completion Fluids, 6h edn., (Gulf Professional Publishing, Boston, 2011), pp. 477–533

J. Argillier, A. Audibert, D. Longeron, Performance evaluation and formation damage potential of new water-based drilling formulas. SPE Drill. Complet. 14, 266–273 (1999)

R. Caenn, H.C.H. Darley, G.R. Gray, Chapter 7 – The filtration properties of drilling fluids11a glossary of notation used in this chapter will be found immediately following this chapter’s text, in Composition and Properties of Drilling and Completion Fluids, ed. by R. Caenn, H. C. H. Darley, G. R. Gray, 7th edn., (Gulf Professional Publishing, Boston, 2017), pp. 245–283

R. Caenn, H.C.H. Darley, G.R. Gray, Chapter 10 – Drilling problems related to drilling fluids, in Composition and Properties of Drilling and Completion Fluids, ed. by R. Caenn, H. C. H. Darley, G. R. Gray, 7th edn., (Gulf Professional Publishing, Boston, 2017), pp. 367–460

A. Suri, M.M. Sharma, Strategies for sizing particles in drilling and completion fluids. SPE J. 9, 13–23 (2004)

M. Dick, T. Heinz, C. Svoboda, M. Aston, Optimizing the selection of bridging particles for reservoir drilling fluids, in SPE International Symposium on Formation Damage Control (2000)

W. He, M. P. Stephens, Bridging particle size distribution in drilling fluid and formation damage, in SPE European Formation Damage Conference (2011)

S. Vickers, M. Cowie, T. Jones, A.J. Twynam, A new methodology that surpasses current bridging theories to efficiently seal a varied pore throat distribution as found in natural reservoir formations. Wiertnictwo, Nafta, Gaz 23, 501–515 (2006)

H.C. Darley, G.R. Gray, Composition and Properties of Drilling and Completion Fluids (Gulf Professional Publishing, Boston, 1988)

F. Civan, Chapter 18-Drilling mud filtrate and solids invasion and mudcake formation, in Reservoir Formation Damage, (Gulf Professional Publishing, Burlington, 2007)

M. Al-Yasiri, D. Wen, Gr-Al2O3 nanoparticles based multi-functional drilling fluid. Ind. Eng. Chem. Res. 58, 23 (2019)

S. M. Javeri, Z. M. W. Haindade, C. B. Jere, Mitigating loss circulation and differential sticking problems using silicon nanoparticles, in SPE/IADC Middle East Drilling Technology Conference and Exhibition (2011)

A. Salih, T. Elshehabi, H. Bilgesu, Impact of nanomaterials on the rheological and filtration properties of water-based drilling fluids, in SPE Eastern Regional Meeting (2016)

A.E. Bayat, P.J. Moghanloo, A. Piroozian, R. Rafati, Experimental investigation of rheological and filtration properties of water-based drilling fluids in presence of various nanoparticles. Colloids Surf. A Physicochem. Eng. Asp. 555, 256–263 (2018)

S.R. Smith, R. Rafati, A. Sharifi Haddad, A. Cooper, H. Hamidi, Application of aluminium oxide nanoparticles to enhance rheological and filtration properties of water based muds at HPHT conditions. Colloids Surf. A Physicochem. Eng. Asp. 537, 361–371 (2018)

M.M. Barry, Y. Jung, J.-K. Lee, T.X. Phuoc, M.K. Chyu, Fluid filtration and rheological properties of nanoparticle additive and intercalated clay hybrid bentonite drilling fluids. J. Pet. Sci. Eng. 127, 338–346 (2015)

Y. Jung, Y.-H. Son, J.-K. Lee, T.X. Phuoc, Y. Soong, M.K. Chyu, Rheological behavior of clay–nanoparticle hybrid-added bentonite suspensions: Specific role of hybrid additives on the gelation of clay-based fluids. ACS Appl. Mater. Interfaces 3, 3515–3522 (2011)

M.-C. Li, Q. Wu, K. Song, C.F. De Hoop, S. Lee, Y. Qing, et al., Cellulose nanocrystals and polyanionic cellulose as additives in bentonite water-based drilling fluids: Rheological modeling and filtration mechanisms. Ind. Eng. Chem. Res. 55, 133–143 (2015)

M.-C. Li, Q. Wu, K. Song, Y. Qing, Y. Wu, Cellulose nanoparticles as modifiers for rheology and fluid loss in bentonite water-based fluids. ACS Appl. Mater. Interfaces 7, 5006–5016 (2015)

L. Liu, X. Pu, K. Rong, Y. Yang, Comb-shaped copolymer as filtrate loss reducer for water-based drilling fluid. J. Appl. Polym. Sci. 135, 45989 (2018)

J.K.M. William, S. Ponmani, R. Samuel, R. Nagarajan, J.S. Sangwai, Effect of CuO and ZnO nanofluids in xanthan gum on thermal, electrical and high pressure rheology of water-based drilling fluids. J. Pet. Sci. Eng. 117, 15–27 (2014)

S.S. Hassani, A. Amrollahi, A. Rashidi, M. Soleymani, S. Rayatdoost, The effect of nanoparticles on the heat transfer properties of drilling fluids. J. Pet. Sci. Eng. 146, 183–190 (2016)

M. Sedaghatzadeh, A. Khodadadi, An improvement in thermal and rheological properties of water-based drilling fluids using multiwall carbon nanotube (MWCNT). Iran. J. Oil Gas Sci. Technol. 1, 55–65 (2012)

J. Cai, M.E. Chenevert, M.M. Sharma, J.E. Friedheim, Decreasing water invasion into Atoka shale using nonmodified silica nanoparticles. SPE Drill. Complet. 27, 103–112 (2012)

P.J. Boul, B. Reddy, J. Zhang, C. Thaemlitz, Functionalized nanosilicas as shale inhibitors in water-based drilling fluids. SPE Drill. Complet. 32, 121–130 (2017)

Y. Kang, J. She, H. Zhang, L. You, M. Song, Strengthening shale wellbore with silica nanoparticles drilling fluid. Petroleum 2, 189–195 (2016)

M. Amanullah, An environment friendly and economically attractive thermal degradation inhibitor for bentonite mud, in SPE Europec/EAGE Annual Conference and Exhibition (2006)

D. Longeron, J. Argillier, A. Audibert, An integrated experimental approach for evaluating formation damage due to drilling and completion fluids, in SPE European Formation Damage Conference (1995)

J.V. Clavijo, L.J. Roldán, L. Valencia, S.H. Lopera, R.D. Zabala, J.C. Cárdenas, et al., Influence of size and surface acidity of silica nanoparticles on inhibition of the formation damage by bentonite-free water-based drilling fluids. Part I: Nanofluid design based on fluid-nanoparticle interaction. Adv. Nat. Sci. Nanosci. Nanotechnol. 10, 045020 (2019)

R. API, 13B-1: Recommended Practice for Field Testing Water-Based Drilling Fluids, and ISO 10414-1 (American Petroleum Institute, Washinton, DC, 2003)

M. Franco-Aguirre, R.D. Zabala, S.H. Lopera, C.A. Franco, F.B. Cortés, Interaction of anionic surfactant-nanoparticles for gas-wettability alteration of sandstone in tight gas-condensate reservoirs. J. Nat. Gas Sci. Eng. 51, 53–64 (2018)

J. Giraldo, P. Benjumea, S. Lopera, F.B. Cortés, M.A. Ruiz, Wettability alteration of sandstone cores by alumina-based nanofluids. Energy Fuel 27, 3659–3665 (2013)

X. Liu, F. Civan, Formation damage and skin factor due to filter cake formation and fines migration in the near-wellbore region," in SPE Formation Damage Control Symposium (1994)

C. Céspedes Chávarro, Desarrollo de un nanofluido para la estabilización de finos de la formación barco del campo Cupiagua (Universidad Nacional de Colombia-Sede Medellín, Medellín)

C. Franco Ariza, F. Cortés, D. Arias-Madrid, E. Taborda, N. Ospina, R. Zabala, et al., "Inhibition of the formation damge due to fine migration on low-permeability reservoirs of sandstone using silica-based nanfluids: from laboratory to a successful field trial.," 2018, p. 231 New York : Nova Science Publishers

C.M. Mera, C.A.F. Ariza, F.B. Cortés, Uso de nanopartículas de sílice para la estabilización de finos en lechos empacados de arena Ottawa. Informador Técnico 77, 27–34 (2013)

C.H. van der Zwaag, Benchmarking the formation damage of drilling fluids, in SPE International Symposium and Exhibition on Formation Damage Control (2004)

L.F. Isernia, FTIR study of the relation, between extra-framework aluminum species and the adsorbed molecular water, and its effect on the acidity in ZSM-5 steamed zeolite. Mater. Res. 16, 792–802 (2013)

B. Gohari, N. Abu-Zahra, Polyethersulfone membranes prepared with 3-aminopropyltriethoxysilane modified alumina nanoparticles for Cu (II) removal from water. ACS Omega 3, 10154–10162 (2018)

J.R. Kennedy, K.E. Kent, J.R. Brown, Rheology of dispersions of xanthan gum, locust bean gum and mixed biopolymer gel with silicon dioxide nanoparticles. Mater. Sci. Eng. C 48, 347–353 (2015)

L.J. Giraldo, M.A. Giraldo, S. Llanos, G. Maya, R.D. Zabala, N.N. Nassar, et al., The effects of SiO2 nanoparticles on the thermal stability and rheological behavior of hydrolyzed polyacrylamide based polymeric solutions. J. Pet. Sci. Eng. 159, 841–852 (2017)

J.J. Adams, Asphaltene adsorption, a literature review. Energy Fuel 28, 2831–2856 (2014)

N.K. Maurya, A. Mandal, Studies on behavior of suspension of silica nanoparticle in aqueous polyacrylamide solution for application in enhanced oil recovery. Pet. Sci. Technol. 34, 429–436 (2016)

A.L. Lorenzen, T.S. Rossi, I.C. Riegel-Vidotti, M. Vidotti, Influence of cationic and anionic micelles in the (sono) chemical synthesis of stable Ni (OH) 2 nanoparticles: “In situ” zeta-potential measurements and electrochemical properties. Appl. Surf. Sci. 455, 357–366 (2018)

R. Caenn, H.C.H. Darley, G.R. Gray, Chapter 6 – The rheology of drilling fluids, in Composition and Properties of Drilling and Completion Fluids, ed. by R. Caenn, H. C. H. Darley, G. R. Gray, 7th edn., (Gulf Professional Publishing, Boston, 2017), pp. 151–244

A.R. Ismail, N.M. Rashid, M.Z. Jaafar, W.R.W. Sulaiman, N.A. Buang, Effect of nanomaterial on the rheology of drilling fluids. J. Appl. Sci. 14, 1192 (2014)

J. Vargas, L. J. Roldán, S. H. Lopera, J. C. Cardenas, R. D. Zabala, C. A. Franco, et al., Effect of silica nanoparticles on thermal stability in bentonite free water-based drilling fluids to improve its rheological and filtration properties after aging process, in Offshore Technology Conference Brasil (2019)

Z. Vryzas, L. Nalbandian, V.T. Zaspalis, V.C. Kelessidis, How different nanoparticles affect the rheological properties of aqueous Wyoming sodium bentonite suspensions. J. Pet. Sci. Eng. 173, 941–954 (2019)

J. Jiang, G. Oberdörster, P. Biswas, Characterization of size, surface charge, and agglomeration state of nanoparticle dispersions for toxicological studies. J. Nanopart. Res. 11, 77–89 (2009)

S. Bentacur, F.B. Cortés, G.A.A. Espinosa, Mejoramiento de los fluidos de perforación usando nanopartículas funcionalizadas: Reducción de las pérdidas de filtrado y del espesor de la retorta. Boletín de Ciencias de la Tierra, 5–14 (2014)

M. Zakaria, M.M. Husein, G. Harland, Novel nanoparticle-based drilling fluid with improved characteristics, in SPE International Oilfield Nanotechnology Conference and Exhibition (2012)

L. Whatley, R. Barati, Z. Kessler, J.-S. Tsau, Water-based drill-in fluid optimization using polyelectrolyte complex nanoparticles as a fluid loss additive, in SPE International Conference on Oilfield Chemistry (2019)

Z. Vryzas, V.C. Kelessidis, M.B.J. Bowman, L. Nalbantian, V. Zaspalis, O. Mahmoud, et al., Smart magnetic drilling fluid with in-situ rheological controllability using Fe3O4 nanoparticles, in SPE Middle East Oil and Gas Show and Conference, MEOS, Proceedings (2017), pp. 2558–2569

J.T. Srivatsa, M.B. Ziaja, An experimental investigation on use of nanoparticles as fluid loss additives in a surfactant – Polymer based drilling fluid, in Society of Petroleum Engineers – International petroleum technology conference 2012, IPTC 2012 (2012), pp. 2436–2454

N.C. Mahajan, B.M. Barron, Bridging particle size distribution: A key factor in the designing of non-damaging completion fluids, in SPE Formation Damage Symposium (1980)

W. Anderson, Wettability literature survey-part 2: Wettability measurement. J. Pet. Technol. 38, 1246–1262 (1986)

A. Cassie, S. Baxter, Wettability of porous surfaces. Trans. Faraday Soc. 40, 546–551 (1944)

K. Kondiparty, A.D. Nikolov, D. Wasan, K.-L. Liu, Dynamic spreading of nanofluids on solids. Part I: Experimental. Langmuir 28, 14618–14623 (2012)

S. Al-Anssari, S. Wang, A. Barifcani, M. Lebedev, S. Iglauer, Effect of temperature and SiO2 nanoparticle size on wettability alteration of oil-wet calcite. Fuel 206, 34–42 (2017)

H. Jang, W. Lee, J. Lee, Nanoparticle dispersion with surface-modified silica nanoparticles and its effect on the wettability alteration of carbonate rocks. Colloids Surf. A Physicochem. Eng. Asp. 554, 261–271 (2018)

C. Franco, E. Patiño, P. Benjumea, M.A. Ruiz, F.B. Cortés, Kinetic and thermodynamic equilibrium of asphaltenes sorption onto nanoparticles of nickel oxide supported on nanoparticulated alumina. Fuel 105, 408–414 (2013)

A. Roustaei, S. Saffarzadeh, M. Mohammadi, An evaluation of modified silica nanoparticles’ efficiency in enhancing oil recovery of light and intermediate oil reservoirs. Egypt. J. Pet. 22, 427–433 (2013)

L.J. Giraldo, J. Gallego, J.P. Villegas, C.A. Franco, F.B. Cortés, Enhanced waterflooding with NiO/SiO2 0-D Janus nanoparticles at low concentration. J. Pet. Sci. Eng. 174, 40–48 (2019)

N.C. Ogolo, O.A. Olafuyi, M. Onyekonwu, Effect of nanoparticles on migrating fines in formations, in SPE International Oilfield Nanotechnology Conference and Exhibition (2012)

W.G. Anderson, Wettability literature survey-part 4: Effects of wettability on capillary pressure. J. Pet. Technol. 39, 1283–1300 (1987)

Acknowledgments

The authors want to thank HOCOL S.A for granting permission to present and publish this paper and Engineers Oscar Medina and Johanna Roldán for their help in the experimental tests. We would also like to recognize the Universidad Nacional de Colombia and Colciencias for logistical and financing assistance in the doctoral studies of Johanna Vargas Clavijo through the announcement of 785/2018.

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Clavijo, J.V. et al. (2021). Double Purpose Drilling Fluid Based on Nanotechnology: Drilling-Induced Formation Damage Reduction and Improvement in Mud Filtrate Quality. In: Nassar, N.N., Cortés, F.B., Franco, C.A. (eds) Nanoparticles: An Emerging Technology for Oil Production and Processing Applications. Lecture Notes in Nanoscale Science and Technology, vol 32. Springer, Cham. https://doi.org/10.1007/978-3-319-12051-5_11

Download citation

DOI: https://doi.org/10.1007/978-3-319-12051-5_11

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-12050-8

Online ISBN: 978-3-319-12051-5

eBook Packages: EngineeringEngineering (R0)