Abstract

Anthropogenic coal fly ash (CFA) is a pozzolanic material comprises silico-alumina, making it an excellent secondary raw material with a range of applications. It is utilized for wastewater treatment, extraction of valuable minerals, and the production of ceramics, cement, concrete, building materials, composites, paints, and plastic materials. The crystalline and amorphous phases of CFA contain metals and metalloid oxides, with the amorphous portion playing a significant role in chemical reactions. However, the direct use of coal fly ash poses challenges due enriched potentially toxic trace elements. Nevertheless, the upstream extraction of valuable minerals and efficient downstream applications of CFA can be improved through mechanical and/or chemical activation. Industrial and laboratory-scale purification and modification of coal fly ash by size reduction, surface modification, and functionalization are discussed in this chapter.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Ahmaruzzaman A (2010) A review on the utilization of fly ash. Prog Energ Combust Sci 36:327–363

Al-Harahsheh MS, AlZboon K, Al-Makhadmeh L, Hararah M, Mahasneh M (2015) Fly ash based geopolymer for heavy metal removal: a case study on copper removal. J Environ Chem Eng 3:1669–1677

Al-Qayim K, Nimmo W, Hughes K, Pourkashanian M (2017) Kinetic parameters of the intrinsic reactivity of woody biomass and coal chars via thermogravimetric analysis. Fuel 210:811–825

Andini S, Cioffi R, Colangelo F, Grieco T, Montagnaro F, Santoro L (2008) Coal fly ash as raw material for the manufacture of geopolymer-based products. Waste Manag 28:416–423

ASTM C 618-00 (2000) Standard specification for coal fly ash and raw or calcined natural pozzolan for use as a mineral admixture in concrete. Annual Book of ASTM Standards, Philadelphia

Aydin S, Karatay C, Baradan B (2010) The effect of grinding process on mechanical properties and alkali-silica reaction of fly ash incorporated cement mortar. Powder Tecnol 197:68–72

Bartoňová L (2015) Unburned carbon from coal combustion ash: an overview. Fuel Process Technol 134:136–158

Bentz DP (2010) Powder additions to mitigate retardation in high-volume fly ash mixtures. ACI Mater J 107:508–514

Bentz DP, Ferraris CF (2010) Rheology and setting of high volume fly ash mixtures. Cem Concr Compos 32:265–270

Bhatt A, Priyadarshini S, Mohanakrishnan AA, Abri A, Sattler M, Techapaphawit S (2019) Physical, chemical, and geotechnical properties of coal fly ash: a global review. Case Stud Constr Mater 11:e00263

Bilgili E, Scarlett B (2005) Population balance modeling of non-linear effects in milling processes. Powder Technol 153:59–71

Bilgili E, Hamey R, Scarlett B (2006) Nano-milling of pigment agglomerates using a wet stirred media mill: elucidation of the kinetics and breakage mechanisms. Chem Eng Sci 61:149–157

Bilodeau A, Malhotra V (2000) High-volume fly ash system: concrete solution for sustainable development. ACI Mater J 97:41–48

Blicharz EG, Panek R, Franus M, Franus W (2022) Mechanochemically assisted coal fly ash conversion into zeolite. Materials 15:7174

Borm JAP (1997) Toxicity and occupational health hazards of coal fly ash (CFA). A review of data and comparision to coal mine dust. Ann Occup Hyg 41:659–676

Bouzoubaa N, Zhang MH, Bilodeau A, Malhotra VM (1997) The effect of grinding on the physical properties of fly ashes and a Portland cement clinker. Cem Concr Res 27:1861–1874

Brouwers HJH, Van Eijk RJ (2002) Reactivity of fly ash: extension and application of a shrinking core model. J Mater Sci 37:2129–2141

Capece M, Bilgili E, Dave R (2011) Identification of the breakage rate and distribution parameters in a non-linear population balance model for batch milling. Powder Technol 208:195–204

Carlson CL, Adriano DC (1993) Environmental impacts of coal combustion residues. J Environ Qual 22:27–247

Chancey RT, Stutzman P, Juenger MCG, Fowler DW (2010) Comprehensive phase characterization of crystalline and amorphous phases of a class F fly ash. Cem Concr Res 40:146–156

Chen Y, Lian X, Li Z, Zheng S, Wang Z (2015) Effects of rotation speed and media density on particle size distribution and structure of ground calcium carbonate in a planetary ball mill. Adv Powder Technol 26:505–510

Dash S, Panda L, Mohanty I, Gupta P (2022) Comparative feasibility analysis of fly ash bricks, clay bricks and fly ash incorporated clay bricks. Mag Civil Eng 115:11502

El Alouani M, Alehyen S, El Achouri M, Taibi MH (2019) Comparative study of the adsorption of micropollutant contained in aqueous phase using coal fly ash and activated coal fly ash: kinetic and isotherm studies. Chem Data Collec 23:100265

Felekoglu B, Trkel S, Kalyoncu H (2009) Optimization of fineness to maximize the strength activity of high-calcium ground fly ash—Portland cement composites. Construct Build Mater 23:2053–2061

Ferrarini SF, Cardoso AM, Paprocki A, Pires M (2016) Integrated synthesis of zeolites using coal fly ash: element distribution in the products, washing waters and effluent. J Braz Chem Soc 27:2034–2045

Gautam S, Guria C, Rajak DK, Pathak AK (2018) Functionalization of fly ash for the substitution of bentonite in drilling fluid. J Petrol Sci Eng 166:63–72

Geng X, Duan Y, Zhao S, Hu J, Zhao W (2021) Mechanism study of mechanochemical bromination on fly ash mercury removal adsorbent. Chemosphere 274:129637

Gollakota AR, Volli V, Shu CM (2019) Progressive utilisation prospects of coal fly ash: a review. Sci Total Environ 672:951–989

Goodarzi F, Sanei H (2009) Plerosphere and its role in reduction of emitted fine fly ash particles from pulverized coal-fired power plants. Fuel 88:382–386

Grabias-Blicharz E, Franus W (2022) A critical review on mechanochemical processing of fly ash and fly ash-derived materials. Sci Total Environ 860:160529

Izquierdo M, Querol X, Davidovits J, Antenucci D, Nugteren H, FernándezPereira C (2009) Coal fly ash-slag-based geopolymers: microstructure and metal leaching. J Hazard Mater 166:561–566

Juenger MCG, Winnefeld F, Provis JL, Ideker JH (2011) Advances in alternative cementitious binders. Cem Concr Res 41:1232–1243

Kaewmee P, Song M, Iwanami M, Tsutsumi H, Takahashi F (2020) Porous and reusable potassium-activated geopolymer adsorbent with high compressive strength fabricated from coal fly ash wastes. J Clean Prod 272:122617

Kapur PC, Fuerstenau DW (1987) Energy-size reduction laws revisited. Int J Miner Process 20:45–57

Kapur PC, Fuerstenau DW, De A (2003) Modelling breakage kinetics in various dry comminution systems. KONA Powder Part J 21:121–132

Kelechi SE, Adamu M, Uche OAU, Okokpujie IP, Ibrahim YE, Obianyo II (2022) A comprehensive review on coal fly ash and its application in the construction industry. Cogent Eng 9:2114201

Khatri C, Rani A (2008) Synthesis of a nano-crystalline solid acid catalyst from fly ash and its catalytic performance. Fuel 87:2886–2892

Khatri C, Jain D, Rani A (2010) Fly ash-supported cerium triflate as an active recyclable solid acid catalyst for Friedel–Crafts acylation reaction. Fuel 89:3853–3859

Kumar S, Kumar R (2011) Mechanical activation of fly ash: effect on reaction structure and properties of resulting geopolymer. Ceram Int 37:533–541

Kumar R, Kumar S, Mehrotra SP (2007) Towards sustainable solutions for fly ash through mechanical activation. Resour Conserv Recy 52:157–179

Kutchko BG, Kim AG (2006) Fly ash characterization by SEM-EDS. Fuel 85:2537–2544

Lee WKW, Van Deventer JSJ (2002) Structural reorganisation of class F fly ash in alkaline silicate solutions. Colloids Surf A Physicochem Eng Aspects 211:49–66

Lee HK, Kim HK, Hwang EA (2010) Utilization of power plant bottom ash as aggregates in fiber-reinforced cellular concrete. Waste Manag 30:274–284

Li MG, Sun CJ, Gau SH, Chuang CJ (2010) Effects of wet ball milling on lead stabilization and particle size variation in municipal solid waste incinerator fly ash. J Hazard Mater 174:586–591

Mio H, Kano J, Saito F, Kaneko K (2004) Optimum revolution and rotational directions and their speeds in planetary ball milling. Int J Miner Process 74:85–92

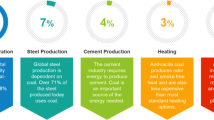

Nidheesh PV, Kumar MS (2019) An overview of environmental sustainability in cement and steel production. J Clean Prod 231:856–871

Nugteren HW, Butselaar-Orthlieb VCL, Izquierdo M (2009) High strength geopolymers produced from coal combustion fly ash. Global NEST J 11:155–161

Page AL, Elseewi A, Straughan IR (1979) Physical and chemical properties of fly ash from coal-fired power plants with reference to environmental impacts. In: Gunther FA, Gunther JD (eds) Residue reviews: residues of pesticides and other contaminants in the total environment. Springer, New York

Palomo, A, Jimenez, FA (2011) Alkaline activation, procedure for transforming fly ash into new materials. Part I: Application. World of coal ash (WOCA) conference, May 9–12, 2011 in Denver, CO, USA

Park J, Bae S (2018) Formation of Fe nanoparticles on water-washed coal fly ash for enhanced reduction of p-nitrophenol. Chemosphere 202:733–741

Patil AG, Anandhan S (2015) Influence of planetary ball milling parameters on the mechano-chemical activation of fly ash. Powder Technol 281:151–158

Paul KT, Satpathy SK, Manna I, Chakraborty KK, Nando GB (2007) Preparation and characterization of nano structured materials from fly ash: a waste from thermal power stations, by high energy ball milling. Nanoscale Res Lett 2:397–404

Pietersen HS (1990) Reactivity of fly ash at high pH. Mater Res Soc Symp Proc 178:139–157

Provis JL, Van Deventer JS (2013) Alkali activated materials: state-of-the-art report, RILEM TC 224-AAM, vol 13. Springer Science & Business Media, South Yorkshire

Rajak DK, Guria C, Ghosh R, Agarwal S, Pathak AK (2016) Alkali assisted dissolution of fly ash: a shrinking core model under finite solution volume condition. Int J Miner Process 155:106–117

Rajak DK, Raj A, Guria C, Pathak AK (2017) Grinding of class-F fly ash using planetary ball mill: a simulation study to determine the breakage kinetics by direct-and back-calculation method. S Afr J Chem Eng 24:135–147

Rezaei H, Shafaei SZ, Abdollahi H, Shahidi A, Ghassa S (2022) A sustainable method for germanium, vanadium and lithium extraction from coal fly ash: sodium salts roasting and organic acids leaching. Fuel 312:122844

Rowles MR, O’Connor BH (2009) Chemical and structural microanalysis of aluminosilicate geopolymers synthesized by sodium silicate activation of metakaolinite. J Am Ceram Soc 92(10):2354–2361. https://doi.org/10.1111/j.1551-2916.2009.03191.x

Schmücker M, MacKenzie KJ (2005) Microstructure of sodium polysialatesiloxo geopolymer. Ceram Int 31:433–437

Sear LKA (2001) Properties and use of coal fly ash: a valuable industrial by-product. Thomas Telford, London

Sharma A (2012) Modification in properties of fly ash through mechanical and chemical activation. Am Chem Sci J 2:177–187

Sharonova OM, Anshits NN, Fedorchak MA, Zhizhaev AM, Anshits AG (2015) Characterization of ferrospheres recovered from high-calcium fly ash. Energy Fuel 29:5404–5414

Singh RK, Gupta NC, Guha BK (2016) Fly ash disposal in ash ponds: a threat to ground water contamination. J Inst Eng India Ser A 97:255–260

Srivastava RR, Rajak DK, Ilyas S, Kim H, Pathak P (2023) Challenges, regulations, and case studies on sustainable management of industrial waste. Fortschr Mineral 13:51

Stockel RF, Bridgewater NJ (1984) Coal ash fertilizer compositions. United States Patent, 4469503

Temuu** J, Minjigmaa A, Rickard W, Lee M, Williams I, vanRiessen A (2010a) Fly ash based geopolymer thin coatings on metal substrates and its thermal evaluation. J Hazard Mater 180:748–752

Temuu** J, VanRiessen A, MacKenzie KJD (2010b) Preparation and characterisation of fly ash based geopolymer mortars. Construct Build Mater 24:1906–1910

The European Committee for Standardization (2012) Fly ash for concrete—part 1: definition, specification and conformity criteria. The European Committee for Standardization (CEN), EN 450-1. Brussels, Belgium

Tian Y, Zhu X, Zhou S, Zhao W, Xu Q, Liu X (2023) Efficient synthesis of alkyl levulinates fuel additives using sulfonic acid functionalized polystyrene coated coal fly ash catalyst. J Bioresour Bioprod 8:198–213

Van Dyk JC, Benson SA, Laumb ML, Waanders B (2009) Coal and coal ash characteristics to understand mineral transformations and slag formation. Fuel 88:1057–1063

Vassilev SV, Vassileva CG (2005) Methods for characterization of cmposition of fly ashes from coal-fired power stations: a critical overview. Energy Fuel 19:1084–1098

Vassilev SV, Menendez R, Alvarez D, Diaz-Somoano M, Martinez-Tarazona MR (2003) Phase-mineral and chemical composition of coal fly ashes as a basis for their multicomponent utilization. 1. Characterization of feed coals and fly ashes. Fuel 82:1793–1811

Wang S (2008) Application of solid ash based catalysts in heterogeneous catalysis. Environ Sci Technol 42:7055–7063

Watanabe H (1999) Critical rotation speed for ball-milling. Powder Technol 104:95–99

Wigley F, Williamson J, Gibb WH (1997) The distribution of mineral matter in pulverised coal particles in relation to burnout behaviour. Fuel 76:1283–1288

**yili H, Çetintaş S, Bingöl D (2017) Removal of some heavy metals onto mechanically activated fly ash: modeling approach for optimization, isotherms, kinetics and thermodynamics. Process Saf Environ Prot 109:288–300

Yadav VK, Fulekar MH (2020) Advances in methods for recovery of ferrous, alumina, and silica nanoparticles from fly ash waste. Ceramics 3:384–420

Zhang L, Ahmari S, Zhang J (2011) Synthesis and characterization of fly ash modified mine tailings-based geopolymers. Construct Build Mater 25:3773–3781

Acknowledgments

The work was supported by Indian Institute of Technology (Indian School of Mines), Dhanbad, India, and Institute of Engineering, Pulchowk Campus, Tribhuvan University, Nepal.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Rajak, D.K., Suman, S., Guria, C., Kumar, G. (2023). Sustainable Utilization of Anthropogenic Coal Fly Ash Through Mechanical and Chemical Activation. In: Pathak, P., Srivastava, R.R., Ilyas, S. (eds) Anthropogenic Environmental Hazards. Springer, Cham. https://doi.org/10.1007/978-3-031-41013-0_7

Download citation

DOI: https://doi.org/10.1007/978-3-031-41013-0_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-41012-3

Online ISBN: 978-3-031-41013-0

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)