Abstract

Thermoeconomics is a science that reconciles thermodynamic and economic concepts. It can be divided into three fields of action: cost allocation, diagnosis and optimization. Most thermoeconomicists agree that exergy is the most appropriate thermodynamic magnitude to associate with cost. In some applications, exergy disaggregation is required. Literature shows several thermoeconomic methodologies. Despite the wide use and their respective fields of action, all models have limitations in the dissipative equipment isolation and waste treatment or an increase in complexity in thermoeconomic modeling. In order to fill part of this scientific gap in thermoeconomics, a recent methodology, the A&F Model, is proposed. This new approach disaggregates physical exergy into just two terms, namely Helmholtz energy and flow work. This work presents for the first time the use of this new approach, through a cost allocation, in a cogeneration system with regenerative gas turbine, and compares it with conventional thermoeconomic methodologies.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Thermoeconomics is a science that combines thermodynamic and economic concepts and can be divided into three fields of application: cost allocation, diagnosis, and optimization. The way the productive structure is defined (input and output) is a key point in thermoeconomic modeling [1], and one of the best thermodynamic magnitudes to associate with the cost is the exergy [2]. Depending on the type of analysis, different levels of accuracy of the results are required, which means that each thermoeconomic analysis requires a specific level of disaggregation of the components and flows [3].

According to [1], the deeper and more detailed the disaggregation, the clearer the interpretation of the costs obtained and the greater the possibility of applications in theoretical and practical problems. By disaggregating the physical exergy, it is possible to obtain better accuracy of the results in the thermoeconomics [4]. Nevertheless, there is a consequent increase in the complexity of thermoeconomic modeling [5]. In this paper, five thermoeconomic models are studied: E, ET & EM [6], H&S [7], UFS [8] and the recent A&F Model [9]. The plant chosen for the analysis allows the approach of a very latent theme in thermoeconomics which is the waste cost allocation.

In order to fill a part of the scientific gap in waste treatment in thermoeconomics, a recent methodology, the A&F Model, has been proposed. This new approach disaggregates the physical exergy into only two terms, namely Helmholtz energy and flow work. This work has chosen the plant used in the CGAM Problem [10] exactly to be able to exemplify how this new methodology treats the residues of a thermal system.

This study presents the use of this new approach, through a cost allocation, in a regenerative gas turbine cogeneration system and compare it with conventional thermoeconomic methodologies highlighting the waste treatment used by each one. The results show that in terms of complexity, the A&F Model is close to the ET&EM and H&S Models and specifically in relation to the UFS Model, it shows a reduction in the number of flows, junction-bifurcations, and cost equations, thus highlighting a lower complexity. It also shows that for the A&F Model, the environment acts as a consistent device in the thermoeconomic analyses of cogeneration systems, allowing the proper internalization of the waste of the thermal system.

2 Thermoeconomic Modeling

The thermoeconomic model is accomplished by using Eq. (1) and (2). The resolution of the cost equation set, Eq. (1), is the monetary unit costs of all internal flow and final product. In Eq. (1), Z represents the external hourly cost of the subsystem due to the capital, operation, and maintenance costs of each subsystem (in $/h); EF is consumption (kW) and cF is the monetary unit cost, both from the external fuel exergy. The unknown variables cout and cin are the monetary unit cost of the internal flows at the outlet and at the inlet of each subsystem (in $/kWh), respectively; and Yout and Yin mean the generic thermodynamic magnitude (power (W), heat exergy (Q), total exergy (E), and physical exergy terms) of the internal flows at inlet and outlet of each subsystem. The solution results in the monetary unit costs of each internal flow and each final product.

In Eq. (2), the unknown kout and kin are the exergetic unit costs of the internal flows (output/input) of each subsystem; and the hourly cost of the subsystem, due to the capital cost, operation, and maintenance, must be zero (Z = 0). Since there is no information about the resource, kF is assumed to be 1.00 kW/kW [3]. The exergetic unit cost of a flow is the amount of external exergy unit required to obtain one unit of this flow, meaning that the exergetic unit cost of a flow is a measure of the thermodynamic efficiency of the production process when producing this flow [3].

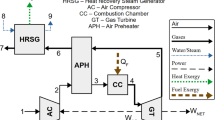

3 Physical Structure

Figure 1 represents the cogeneration system with a regenerative gas turbine of the CGAM Problem [10]. The system is composed of: air compressor (AC), regenerator (R), combustion chamber (CC), gas turbine (GT), and recovery boiler (RB). The operating parameters are the same as for the CGAM Problem [10].

4 Thermoeconomic Methodologies

In this work, four conventional methodologies and the recent approach A&F Model are applied. The exergy and monetary unit costs are calculated for all of them.

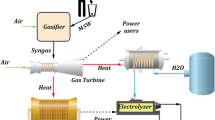

4.1 A&F Model

The A&F Model [9] is a recent thermoeconomic approach, it was developed with the premise of reducing the complexity and computational efforts compared to other methodologies that are capable of isolating (defining input and output) dissipative equipment, such as a valve. This model also uses the physical exergy disaggregation and the definition of its terms are Helmholtz energy EA and flow work EF. They can be estimated, specifically by Eq. (3) and (4), which together with chemical exergy are used to define the productive flows for this model. It is important to highlight that the Helmholtz energy term can be mathematically interpreted as a combination of the internal energy (EU) and the entropic (ES) terms. However, it is worth mentioning that this combination is not simply and purely a mathematical algebraic, it presents a consistent thermodynamic concept, characterized by the Helmholtz energy. Figure 2 illustrates the productive diagram for the cogeneration system using the A&F Model. Regarding waste cost treatment, this methodology uses the environmental device (E) in its modeling. It is worth mentioning that the internalization of waste costs is initially through Helmholtz energy term (EA1:7).

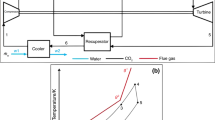

4.2 Conventional Methodologies

The conventional methodologies studied in this work are E, ET&EM, H&S, and UFS Models. Figure 3 illustrates the productive diagrams for these methodologies, besides highlighting the internalization of waste cost.

5 Results

Figure 4 presents the monetary and exergy unit costs for the five thermoeconomic models applied to the regenerative gas turbine cogeneration system. It can be observed that the results present a linear trend, which implies coherent results from a thermoeconomic point of view. Specifically, in relation to the A&F Model, it is noted that their respective results present a high degree of similarity with the E Model. This is an interesting result since for thermal systems, where dissipative equipment is not present, the E Model is widely used and accepted from the scientific point of view.

Averaging between the extremes arrives at a value of 29.58 and 36.05 ($/MWh) for the monetary unit cost of power and heat, respectively. Analogously, an average value of 1.86 and 2.23 (kW/kW) are reached for the exergy unit cost of power and heat. These values are close to those obtained by the A&F Model, respectively 28.51 and 38.57 ($/MWh) and 1.81 and 2.36 (kW/kW).

6 Conclusions

This work presented the use of a recent approach for exergy disaggregation in a regenerative gas turbine cogeneration system, called the A&F Model, which is a consistent alternative for total disaggregation of the system in thermoeconomic modeling, especially when there are dissipative components and waste in the system under analysis. Nonetheless, it is worth noting that in this work, the focus was directed on waste treatment. The two physical exergy terms in this model have a thermodynamic meaning: Helmholtz energy and flow work. Regarding waste treatment, the A&F Model uses the environmental device, through its respective product. Its internalization initializes with the Helmontz energy term. The cost results showed a small variation from an average cost value, for both unit costs, which leads to an interpretation of improved precision of the results rather than a large difference between the methodologies regarding waste treatment for this plant. Finally, besides having applied the A&F Model to the regenerative gas turbine cogeneration system and compared its results with conventional methodologies, this work presented this recent approach to disaggregate physical exergy as a coherent and consistent alternative to solve a difficult problem in thermoeconomics related to the waste treatment of thermal systems, besides presenting a lower complexity in thermoeconomic modeling, since the disaggregation of physical exergy is performed in two terms only.

References

Lozano, M.A.; Valero, A. Thermoeconomic Analysis of Gas Turbine Cogeneration Systems. ASME, NEW YORK, NY,(USA). 1993, 30, 311–320

Valero, A.: Exergy Accounting: Capabilities and Drawbacks. Energy 31, 164–180 (2006). https://doi.org/10.1016/j.energy.2004.04.054

Valero, A.; Serra, L.; Uche, J. Fundamentals of Exergy Cost Accounting and Thermoeconomics. Part I: Theory. J Energy Resour Technol 2006, 128, 1–8, doi:https://doi.org/10.1115/1.2134732

Lazzaretto, A., Tsatsaronis, G.: SPECO: A Systematic and General Methodology for Calculating Efficiencies and Costs in Thermal Systems. Energy 31, 1257–1289 (2006). https://doi.org/10.1016/j.energy.2005.03.011

Arena, A.P., Borchiellini, R.: Application of Different Productive Structures for Thermoeconomic Diagnosis of a Combined Cycle Power Plant. Intl. J. of Thermal Sciences 38, 601–612 (1999). https://doi.org/10.1016/S0035-3159(99)80040-3

Frangopoulos, C.A.: Application of the Thermoeconomic Functional Approach to the CGAM Problem. Energy 19, 323–342 (1994). https://doi.org/10.1016/0360-5442(94)90114-7

Santos, J.J.C.S., et al.: On the Negentropy Application in Thermoeconomics: A Fictitious or an Exergy Component Flow? Intl. J. of Thermodynamics 12, 163–176 (2009)

Lourenço, A.B., Santos, J.J.C.S.; Donatelli, J.L.M. Thermoeconomic modeling of a simple heat pump cycle: an alternative approach for valve isolation. In: Mitrović, D., Laković, M. (eds.) Proceedings of the 15th Symposium on Thermal Science and Engineering Serbia; Sokobanja, Serbia. SimTerm 2011, pp. 453–446 (2011)

dos Santos, R.G., Lourenço, A.B., de Faria, P.R., Barone, M.A., Santos, J.J.C.S.: A new exergy disaggregation approach for complexity reduction and dissipative equipment isolation in thermoeconomics. Entropy 24, 1672 (2022). https://doi.org/10.3390/e24111672

Valero, A., et al.: CGAM problem: definition and conventional solution. Energy 19, 279–286 (1994). https://doi.org/10.1016/0360-5442(94)90112-0

Acknowledgments

The authors would like to thank them FAPES, IFES, CAPES, CNPq, and UFES.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

dos Santos, R.G., Lourenço, A.B., de Faria, P.R., Belisario, I.C., Barone, M.A., Santos, J.J.C.S. (2023). A Comparative Study of the Recent A&F Model with Conventional Thermoeconomic Methodologies in the Waste Treatment in a Regenerative Gas Turbine Cogeneration System. In: Vizán Idoipe, A., García Prada, J.C. (eds) Proceedings of the XV Ibero-American Congress of Mechanical Engineering. IACME 2022. Springer, Cham. https://doi.org/10.1007/978-3-031-38563-6_35

Download citation

DOI: https://doi.org/10.1007/978-3-031-38563-6_35

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-38562-9

Online ISBN: 978-3-031-38563-6

eBook Packages: EngineeringEngineering (R0)