Abstract

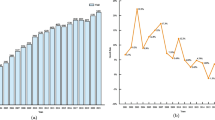

Large forging parts widely adopted in oil rigs, wind mills, large vessels and other complex equipment often carry random forging defects such as parting lines, burrs and high islands, which are traditionally removed through manual grinding by skilled operators. These random defects pose a big challenge to researchers interested in large forging parts grinding path generation by a CAD/CAM system. This paper proposes a new path generation method based on intelligent defect recognition of robotic grinding for large forging parts. A point cloud is first constructed of random defects on the surfaces of the to-be-ground parts from the unmatched points that emerge from the matching of the point clouds captured by a laser camera from the parts against those from the standard parts, a process employing both a random sample consensus algorithm and a modified iterative closest point algorithm. Then, the grinding path generation strategy is established by sorting the random defects according to a law of area on the fitting surface and robotic grinding motion programs are generated by transferring the coordinates of the random defects from the laser camera frame into the robot base frame. Finally, robotic grinding tests are conducted to verify the identification accuracy of the proposed new method. Results of the tests indicate that the method has accurately identified all random defects on a 10-m long forging part and intelligently generated subsequent robotic grinding paths according to the identified random feature categories. This study therefore provides an intelligent tool for finishing large forging parts.

S. Yan, Q. Wang—Authors with equal contributions.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Kafle, A., Shrestha, P.L., Chitrakar, S., et al.: A review on casting technology with the prospects on its application for hydro turbines. J. Phys. Conf. Ser. 1608 (2020)

Prabhakar, A., Papanikolaou, M., Salonitis, K., Jolly, M., et al.: Minimising defect formation in sand casting of sheet lead: a DoE approach. Metals-Open Access Metall. J. 10(2), 252 (2020)

Zhang, M., Chen, T., Tan, Y., et al.: An adaptive grinding method for precision-cast blades with geometric deviation. Int. J. Adv. Manuf. Technol. (3) (2020)

**ao, W., Liu, G., Zhao, G.: Generating the tool path directly with point cloud for aero-engine blades repair. Proc. Inst. Mech. Eng. 235(5) (2021)

Di, D., Polden, J., Dong, J., et al.: Sensor guided robot path generation for surface repair tasks on a large scale buoyancy module. IEEE/ASME Trans. Mechatron. 23(2), 636–645 (2018)

Ma, K., Han, L., Sun, X., et al.: A path planning method of robotic belt grinding for workpieces with complex surfaces. IEEE/ASME Trans. Mechatron. PP(99), 1 (2020)

Wang, W., Yun, C.: A path planning method for robotic belt surface grinding. Chin. J. Aeronaut. 24(004), 520–526 (2011)

Lv, Y., Peng, Z., Qu, C., et al.: An adaptive trajectory planning algorithm for robotic belt grinding of blade leading and trailing edges based on material removal profile model. Robot. Comput.-Integr. Manuf. 66, 101987 (2020)

Wang, W., Liu, F., et al.: Prediction of depth of cut for robotic belt grinding. Int. J. Adv. Manuf. Technol. 91(1–4), 699–708 (2017)

Li, S., Wang, J., Liang, Z., et al.: Tree point clouds registration using an improved ICP algorithm based on kd-tree. In: IGARSS 2016–2016 IEEE International Geoscience and Remote Sensing Symposium. IEEE (2016)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Switzerland AG

About this paper

Cite this paper

Yan, S., Wang, Q., Su, P., Wang, W. (2021). An Intelligent Path Generation Method of Robotic Grinding for Large Forging Parts. In: Liu, XJ., Nie, Z., Yu, J., **e, F., Song, R. (eds) Intelligent Robotics and Applications. ICIRA 2021. Lecture Notes in Computer Science(), vol 13015. Springer, Cham. https://doi.org/10.1007/978-3-030-89134-3_1

Download citation

DOI: https://doi.org/10.1007/978-3-030-89134-3_1

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-89133-6

Online ISBN: 978-3-030-89134-3

eBook Packages: Computer ScienceComputer Science (R0)