Abstract

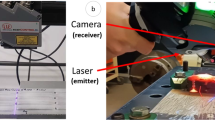

Shorter production times, associated with sheet-bulk metal forming (SBMF), require a demand-adapted monitoring and measurement of the formed geometries. In the present work, a multi-scale and multi-sensor setup was developed to meet these requirements. The difficulty in measuring workpieces formed during SBMF are highly reflective areas with varying demands on the measurement resolution of the functional elements. With the developed measurement setup and the integrated sensors used, the functional elements can be measured with sufficient resolution. The registration of the sensors is done with a specially constructed calibration plate. A parallel kinematic hexapod positioning unit provides six degrees of freedom to precisely position the workpiece in front of the individual measurement sensors. The hexapod is therefore registered in a global coordinate system with the new calibration plate. After the calibration, the measured datasets can be merged together automatically. The rigid connection of the calibration plate to the hexapod enables a more demand-oriented verification of the registration between the individual measurements of the sensors. For overexposure due to directly reflecting areas, it is possible to estimate the quality of each reconstructed data point. A deflectometry system, which is attached to the existing fringe projection sensor, makes it possible to detect strongly directionally reflecting areas and thus provide a holistic reconstruction of the workpiece. The influence of remaining lubricant on the workpiece is simulated by a developed thin film thickness standard. This is to adapt the measuring procedure for reconstructions under harsh conditions in industrial environment. This standard allows the measurement of thin films with the existing optical measurement systems in a range <100 µm. The effects of thin layers of lubricant on the result of the fringe projection measurements show an increasing impact on the measured dataset with increasing layer thickness. With the developed measurement setup, the investigations on the lubricant used and reflective properties, the formed workpieces can be measured at different scale ranges.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Merklein, M., Allwood, J.M., Behrens, B.A., Brosius, A., Hagenah, H., Kuzman, K., Mori, K., Tekkaya, A.E., Weckenmann, A.: Bulk forming of sheet metal. CIRP Ann. Manuf. Technol. 61(2), 725–745 (2012)

Metzner, S., Hausotte, T., Loderer, A.: Ganzheitliche dimensionelle Messung von blechmassivumgeformten Bauteilen. In: Technisches Messen (2017). https://doi.org/10.1515/teme-2016-0071, ISSN 0171-8096

Bauer, N.: Handbuch zur industriellen Bildverarbeitung: Qualitätssicherung in der Praxis. Frauenhofer IRB Verlag Stuttgart (2007)

Metzner, S., Ramesh, R., Hausotte, T.: Local histogram equalization and homomorphic filtering to improve wide-angle stereo disparity computation. Forum Bildverarbeitung (2018). https://doi.org/10.5445/ksp/1000085290

Matthias, S., Loderer, A., Koch, S., Gröne, M., Kästner, M., Hübner, S., Krimm, R., Reithmeier, E., Hausotte, T., Behrens, B.: Metrological solutions for an adapted inspection of parts and tools of a sheet-bulk metal forming process. Prod. Eng. 10(1), (2016). https://doi.org/10.1007/s11740-015-0647-2

VDI 2221:1993, Methodik zum Entwickeln und Konstruieren technischer Systeme und Produkte (1993)

Metzner, S., Ramesh,R., Müller, A., Hausotte, T.: Evaluation of reflection properties of sheet bulk metal formed parts by pixel wise analysis of camera images provided for triangulation measurement. 19. ITG/GMA-Fachtagung Sensoren und Messsysteme In: ITG-Fachbericht 281 Sensoren und Messsysteme, Berlin (2018)

Metzner, S., Reuter, T., Hausotte, T.: Evaluation on influences of thin lubricant on fringe projection measurements. In: Optics and Photonics International Congress. SPIE: Optical Technology and Measurement for Industrial Applications (2019). https://doi.org/10.1117/12.2535570

Loderer, A.: Holistische, Fertigungsnahe, Mehrskalige Messung Blechmassivumgeformter Bauteile. Friedrich-Alexander-Universität Erlangen-Nürnberg, Doctoralthesis (2017)

Metzner, S., Hausotte,T.: Holistic dimensional measurement of sheet-bulk metal formed parts. SPIE/COS Photonics Asia, Bei**g. In: Proceedings - Optical Metrology and Inspection for Industrial Applications, vol. 10819 (2018), https://doi.org/10.1117/12.2501255

Metzner, S. Hausotte, T.: Extension of the registration possibilities and determination of the positioning precision of a multi-scale fringe projection. In: Dimensional Optical Metrology and Inspection for Practical Applications IX, SPIE (2020). https://doi.org/10.1117/12.2558029

Metzner, S., Hausotte, T.: Automatic camera calibration and sensor registration of a multi-sensor fringe measurement system using hexapod positioning. In: SPIE Optical Metrology, In: SPIE (Hrsg.): Proceedings of the SPIE 11056, Optical Measurement Systems for Industrial Inspection XI, 1105616(2019), https://doi.org/10.1117/12.2526122

DIN EN ISO 10360-3:2000-08: Geometrische Produktspezifikation (GPS) - Annahmeprüfung und Bestätigungsprüfung für Koordinatenmessgeräte (KMG) - Teil 3 (2000)

Matthias, M., Kästner, E.: Reithmeier: Modeling of imagingfiber bundles and adapted signal processing for fringe projection. Advanced Optical Technologies (2016), https://doi.org/10.1515/aot-2016-0050

Metzner, S., Reuter, T., Hausotte, T.: Measurement of the Beruforge 152DL thin-film lubricant using a developed thin-film thickness standard. J. Sens. Sen. Syst. 9, 157–165 (2020). https://doi.org/10.5194/jsss-9-157-2020

Metzner, S., Knippen, W., Hausotte, T.: Interferometrische Messung der Positioniergenauigkeit und Verkippung einer Hexapod-Positioniereinheit. 23. Umformtechnisches Kolloquium Hannover. In: Behrens B (Hrsg.): Aktuelle Entwicklungen im Bereich der Umformtechnik, Hannover (2020)

Cardin, J., Leduc, D.: Determination of refractive index, thickness, and the optical losses of thin films from prism-film coupling measurements. Appl. Opt., Bd.. 47, S. 894 (2008). https://doi.org/10.1364/ao.47.000894

Jakob, G.: Koaxiale interferometrische Schichtdickenmessung. Photonik, Nr. 3 (2000)

Lehmann, P., **e, W., Allendorf, B., Tereschenko, S.: Coherence scanning and phase imaging optical interference microscopy at the lateral resolution limit. Opt. Express 26, 7376 (2018). https://doi.org/10.1364/oe.26.007376

Metzner, S., Reuter, T., Wirthmann, E., Hausotte, T.: Bestimmung des Brechungsindex des Schmiermittels Beruforge 152DL unter Verwendung eines dafür entwickelten Dünnschichtnormals 20. GMA/ITG-Fachtagung Sensoren und Messsysteme (2019). https://doi.org/10.5162/sensoren2019/5.1.4

Quinten, M.: Optische Schichtdickenmessung mit miniaturisierten Spektrometern. Books on Demand (2015), S.32, ISBN: 978-3734783869

Knauer, M.C.: Absolute Phasenmessende Deflektometrie, Institut für Optik, Information und Photonik, Friedrich-Alexander-University Erlangen (2006)

Weckenmann, A., Akkasoglu, G.: Maturity Model for the development of new forming processes applied to the Sheet-Bulk Metal Forming. In: Key Engineering Materials, 504, Schweiz: Trans Tech Publications (2012)

Acknowledgment

This study was supported by the German Research Foundation (DFG) within the scope of the Transregional Collaborative Research Centre for sheet-bulk metal forming (TCRC 73, Subproject A06) under grant number 68237143. The authors are in addition grateful to all laboratory assistants and students who supported the realisation of this work.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Switzerland AG

About this paper

Cite this paper

Metzner, S., Hausotte, T., Loderer, A. (2021). Strategies for Function-Oriented Optical Inspection of Formed Precision Workpieces. In: Merklein, M., Tekkaya, A.E., Behrens, BA. (eds) Sheet Bulk Metal Forming . TCRC73 2020. Lecture Notes in Production Engineering. Springer, Cham. https://doi.org/10.1007/978-3-030-61902-2_4

Download citation

DOI: https://doi.org/10.1007/978-3-030-61902-2_4

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-61901-5

Online ISBN: 978-3-030-61902-2

eBook Packages: EngineeringEngineering (R0)