Abstract

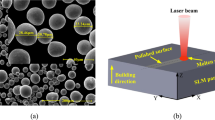

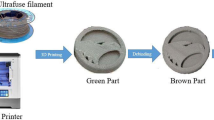

The selective laser melting (SLM) is an additive manufacturing process applied to fabricate the metal parts owing to the melting of the metal powder in a layer by layer approach. The combined thermo-mechanical techniques for the post-processing of Ni-Cr-Fe alloy parts fabricated by the SLM process are proposed. In this study, the flat parts were fabricated using a nickel-based pre-alloyed Inconel 718 powder. The hot isostatic pressing (HIP) followed by homogenization (H) and/or aging (A) was carried out to modify the structure of the material and reduce the porosity. The shot peening (SP) and ultrasonic impact treatment (UIT) using a seven-pin impact head were applied to improve the surface texture parameters and stress state. The surface texture and hardness of the SLM-built and thermo-mechanical post-processed Inconel 718 specimens are studied and compared. Results indicated that the used mechanical surface treatments after heat treatments led to a further increase in the surface hardness and formation of a new surface microrelief. As compared to the SP process, the UIT process forms regular microrelief with smoother surface roughness and lower height profile parameters while the SP-induced surface hardness is higher than that of the UIT-processed specimen.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Fousova, M., et al.: Influence of inherent surface and internal defects on mechanical properties of additively manufactured Ti6Al4V alloy: comparison between selective laser melting and electron beam melting. Materials 11, 537 (2018)

Herzog, D., et al.: Additive manufacturing of metals. Acta Mater. 177, 371–392 (2016)

Renderos, M., et al.: Microstructure characterization of recycled IN718 powder and resulting laser clad material. Mater. Character. 134, 103–113 (2017)

Gonzalez-Gutierrez, J., et al.: Additive manufacturing of metallic and ceramic components by the material extrusion of highly-filled polymers: a review and future perspectives. Mater. 11, 840 (2018)

Zhang, Y., et al.: Additive manufacturing of metallic materials: a review. J. Mater. Eng. Perform. 27, 1–13 (2018)

Pereira, T., et al.: A comparison of traditional manufacturing vs additive manufacturing, the best method for the job. Proc. Manuf. 30, 11–18 (2019)

Tucho, W.M., et al.: Microstructure and hardness studies of Inconel 718 manufactured by selective laser melting before and after solution heat treatment. Mater. Sci. Eng. A 689, 220–232 (2017)

Raghavan, R., et al.: Effect of different heat treatments on the microstructure and mechanical properties in selective laser melting INCONEL 718 alloy. Mater. Manuf. Process. 32, 1588–1595 (2017)

Kuo, Y.-L., et al.: The effect of post-processes on the microstructure and creep properties of alloy 718 built up by selective laser melting: a review. Materials 11, 996 (2018)

Boschetto, A., et al.: Surface roughness and radiusing of Ti6Al4V selective laser melting-manufactured parts conditioned by barrel finishing. Int. J. Adv. Manuf. Technol. 94, 2773–2790 (2018)

Bankowski, D., et al.: Vibratory machining effect on the properties of the aluminum alloys surface. Arch. Foundry Eng. 17, 19–24 (2017)

Bagherifard, C.S., et al.: On the fatigue strength enhancement of additive manufactured AlSi10Mg parts by mechanical and thermal post-processing. Mater. Des. 145, 28–41 (2018)

Soyama, H., et al.: The use of various peening methods to improve the fatigue strength of titanium alloy Ti6Al4V manufactured by electron beam melting. AIMS Mater. Sci. 5, 1000–1015 (2018)

Sealy, M.P., et al.: Fatigue performance of biodegradable magnesium–calcium alloy processed by laser shock peening for orthopedic implants. Int. J. Fatigue 82, 428–436 (2016)

Kim, J.D., et al.: Mechanical and tribological characteristics of sintered Fe-Ni-Cr alloy subjected to high-frequency ultrasonic peening. Int. J. Surf. Sci. Eng. 8, 239–254 (2014)

**ng, X., et al.: Ultrasonic peening treatment used to improve stress corrosion resistance of AlSi10Mg components fabricated using selective laser melting. Metals 9, 103–111 (2019)

Lesyk, D.A., et al.: Post-processing of the Inconel 718 alloy parts fabricated by selective laser melting: effects of mechanical surface treatments on surface topography, porosity, hardness and residual stress. Surf. Coat. Technol. 381, 125136 (2020)

Zhang, M., et al.: Residual stress, defects and grain morphology of Ti-6Al-4V alloy produced by ultrasonic impact treatment assisted selective laser melting. Appl. Sci. 6, 304–311 (2016)

Yan, X., et al.: Fatigue strength improvement of selective laser melted Ti6Al4V using ultrasonic surface mechanical attrition. Mater. Res. Lett. 7, 327–333 (2019)

Lesyk, D.A., et al.: Surface finishing of complexly shaped parts fabricated by selective laser melting. In: Grabchenko’s International Conference on Advanced Manufacturing Processes. InterPartner-2019. Lecture Notes Mechanical Engineering, pp. 186–195. Springer, Cham (2018)

Lesyk, D.A., et al.: Surface microrelief and hardness of laser hardened and ultrasonically peened AISI D2 tool steel. Surf. Coat. Technol. 278, 108–120 (2015)

Lesyk, D.A., et al.: Effects of laser heat treatment combined with ultrasonic impact treatment on the surface topography and hardness of carbon steel AISI 1045. Opt. Laser Technol. 111, 424–438 (2019)

Seede, R., et al.: Microstructural and microhardness evolution from homogenization and hot isostatic pressing on selective laser melted Inconel 718: structure, texture, and phases. Manuf. Mater. Process. 2, 30 (2018)

Lesyk, D.A., et al.: Surface finishing of complexly shaped parts fabricated by selective laser melting. In: Grabchenko’s International Conference on Advanced Manufacturing Processes. InterPartner-2019, pp. 186–195. LNME, Cham (2020)

Acknowledgments

The authors would like to acknowledge S. Faust (Otto von Guericke University Magdeburg, Germany) for the surface topography measurements.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 The Editor(s) (if applicable) and The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Lesyk, D., Martinez, S., Pedash, O., Dzhemelinskyi, V., Mordyuk, B. (2020). Combined Thermo-Mechanical Techniques for Post-processing of the SLM-Printed Ni-Cr-Fe Alloy Parts. In: Ivanov, V., Trojanowska, J., Pavlenko, I., Zajac, J., Peraković, D. (eds) Advances in Design, Simulation and Manufacturing III. DSMIE 2020. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-030-50794-7_29

Download citation

DOI: https://doi.org/10.1007/978-3-030-50794-7_29

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-50793-0

Online ISBN: 978-3-030-50794-7

eBook Packages: EngineeringEngineering (R0)