Search

Search Results

-

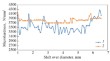

Influence of Route Multiplicity and Drawing Rate on Microhardness Distribution Over Steel Wire Cross Section

An experimental and finite element study of the effect of the multiplicity of wire drawing regime stages and wire drawing speed on microhardness...

-

Thermophysical Characteristics of Furnace Tiles Obtained Using Galvanic Production Wastes

The results of research on the possibility of using galvanic sludge as components of the raw material composition for the manufacture of furnace...

-

Appraisal of modern mini mills

The technological, economic, and energy indices of high-technology modern metallurgical plants are analyzed.

-

Production of Keramzit Gravel Using Galvanic Sludge

The possibility of used galvanic sludge in the production of keramzit was studied. It was determined that there is a relation between the...

-

Thermomechanical treatment of high-carbon wire rod in the 150 high-speed wire mill at Belorussian Metallurgical Plant

The introduction of a reduction and calibration unit at a wire mill is recommended for the production of high-carbon wire rod subjected to...

-

Use of electroplating sludge for ceramic brick manufacture

The migration of heavy metal ions (Zn 2+ , Cu 2+ , Cr 3+ , Cr 6+ , Ni 2+ , Fe 2+ and Fe 3+ ) from ceramic brick containing sludge from electroplating is...

-

Production of mold sleeves of VM-Sinus type

The introduction of mold sleeves of VM-Sinus type is considered, as well as their manufacturing technology at Belorussian Metallurgical Plant.

-

Steelmaking. Use of refractory materials. Correction of trends. Predictions

An analysis of the development in 2011 of ferrous metallurgy, the principal consumer of refractory materials, together with predictions for the...

-

Influence of surface defects inherited by wire rod on the quality of cold-drawn wire

The factors that have the most influence on the drawing of high-carbon wire—the surface defects, shape, and storage of the wire rod employed—are...

-

Reducing the energy consumption in steel smelting in large high-power arc furnaces

Stages in the modernization of the basic steel-production systems at the Belorussian Metallurgical Plant are considered. The state-of-the-art...

-

Development of refractory production in the world and in Russia, new technologies

It is noted that under conditions of increasing competition among refractory producers there is a greater tendency of Russian refractory...

-

Temperature considerations in optimizing drawplate-channel geometry

A method is proposed for selecting the geometry of deforming and calibrating zones of the drawplate so as to minimize the surface temperature of the...

-

Introducing the production of A700HW rebar at the 320 mill

Production technology is proposed for thermomechanically strengthened A700HW steel rebar of periodic profile 12, 14, and 16 in accordance with the...

-

Heating steel in annular furnaces

The heating of cylindrical billet in annular furnaces in shaft and pipe rolling is investigated. The laws of billet heating and rough-shaft heat...

-

Improving the heating system and structure of shaft furnaces for roasting limestone

Improvements in the thermal system of counterflow shaft furnaces—including the heating systems, burners, gas-distribution units, and control...

-

A decade of quality steel production: Develo** a production technology for steel used in metal-cord manufacture

The introduction of high-carbon wire-rod production at OAO Moldavskii Metallurgicheskii Zavod is considered, with particular attention to wire rod...

-

Improving the wear resistance of slip** cathode contacts in the brass-plating of wire for metal cord

To increase the working life of slip** cathode contacts on systems for brass-plating metal-cord blanks, argon-arc surfacing of chemicothermally...

-

Rational use of soluble anodes

The use of soluble copper anodes in the brass plating of wire is optimized. The selection of material for insoluble anodes is considered.