Collection

Recent Advances in the Computational-Based Analysis of Metal Joining

- Submission status

- Closed

Advancement in dissimilar materials joining technologies has improved assembled components' integrity and performance leading to the development of advanced manufacturing techniques that provide extraordinary benefits such as increased productivity, component cost reduction, synergistic mixes of materials, unique joint properties, and improved joint efficiency. The main focus of this Special Issue addresses the growing research in optimization techniques and their applications. To reduce the waste of time, a numerical-based analysis is recommended.

This collection is dedicated to advanced welding analysis, such as:

- Computational-based analysis of the welded joints.

- Optimization of welding parameters

- Cold metal transfer (CMT)

- Nanoparticles in different types of welding

- Underwater welding

- Topics related to the welding and joining, including metallurgical characterization, mechanical properties, and computational base analysis in extreme environments.

Editors

-

Dr Husain Mehdi

Meerut Institute of Engineering and Technology, India Husain Mehdi currently working as an Associate professor in the department of Mechanical Engineering at Meerut Institute of Engineering and Technology Meerut. Husain does research in Industrial Design and Educational Technology. Their current project is 'Friction Stir Welding'.

-

Dr. Velaphi Msomi

Cape Peninsula University of Technology, South Africa Research Interests: - Friction stir welding, friction stir processing, friction stir additive manufacturing - Renewable energy-based desalination systems - Metal matrix materials – manufacture, properties and characterisation - Surface metal composites – manufacture, properties and characterisation

Articles (22 in this collection)

-

-

Numerical and experimental investigation of autogenous GTAW weld between IN 718/ASS 304L

Authors (first, second and last of 4)

- Niraj Kumar

- Prakash Kumar

- Chandan Pandey

- Content type: Original Article

- Published: 16 March 2024

- Pages: 1523 - 1538

-

Examination of electrochemical machining parameters for AA6082/ZrSiO4/SiC composite using Taguchi-ANN approach

Authors (first, second and last of 9)

- K. Srividya

- S. Ravichandran

- Javvadi Eswara Manikanta

- Content type: Original Article

- Published: 13 March 2024

- Pages: 1459 - 1473

-

An overview of cold metal transfer welding of similar materials

Authors

- Indra Jeet Singh

- Paras Kumar

- Qasim Murtaza

- Content type: Review

- Published: 24 January 2024

- Pages: 1845 - 1861

-

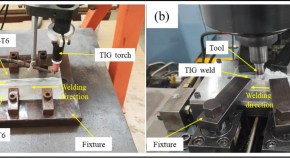

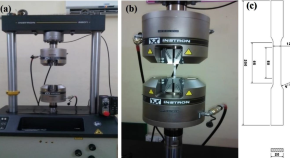

Improving tensile strength, impact toughness and wear resistance of TIG welded dissimilar AA7075-T6/AA6061-T6 joints through friction stir processing

Authors

- Md Saquib Bin Reyaz

- Amar Nath Sinha

- Content type: Original Article

- Published: 17 January 2024

- Pages: 1387 - 1400

-

Effect of tool probe geometry on the material flow and mechanical behaviour of dissimilar AA2024/AA7075 friction stir welded joints

Authors

- B. Nikhil

- P. Govindan

- Content type: Original Article

- Published: 12 January 2024

- Pages: 1645 - 1664

-

Optimization of erosion parameters of coated SS316L using Taguchi method

Authors

- Piyush Mahendru

- Content type: Original Article

- Published: 12 January 2024

- Pages: 1575 - 1591

-

Fatigue life of super duplex stainless steel sheets (UNS S32750) as influenced by micro plasma arc welding parameters: an investigation using the surface response method

Authors

- Sasidhar Gurugubelli

- V. V.S. Kesava Rao

- Content type: Original Article

- Published: 12 January 2024

- Pages: 1183 - 1193

-

Investigation on mechanical and wear performance of friction stir processed on GMAW cladded AA5083/ER4043

Authors (first, second and last of 6)

- Akant Pareek

- **esh Kumar Jain

- Ashish Saxena

- Content type: Original Article

- Published: 10 January 2024

- Pages: 1401 - 1414

-

Design, development and metrological investigations of EN 24 steel based square ring shaped force transducer

Authors (first, second and last of 5)

- Harish Kumar

- Ajay P. Singh

- Sudhir Kumar

- Content type: Original Article

- Published: 06 January 2024

- Pages: 1539 - 1555

-

Experimental analysis and investigation on enhanced tribological performance of self-healing Al6061–60Pb40Sn solder alloy reinforcement

Authors

- Nitin Kumar Gupta

- Nalin Somani

- G. D. Thakre

- Content type: Original Article

- Published: 02 January 2024

- Pages: 1267 - 1278

-

Friction and wear optimization of SiC/graphite reinforced AZ31 hybrid composite using Taguchi method

Authors (first, second and last of 9)

- Itha Veeranjaneyulu

- V. Haripriya

- Ram Subbiah

- Content type: Original Article

- Published: 22 December 2023

- Pages: 1373 - 1386

-

A statistical analysis on effect of process parameters on tensile, flexural, and hardness characteristics of wood–polylactic acid composites using FDM 3D printing

Authors (first, second and last of 5)

- Abhay Mishra

- Rajeev Kumar

- Nalin Somani

- Content type: Original Article

- Published: 19 December 2023

- Pages: 1303 - 1315

-

Microstructural and mechanical response of SiC and TiO2 particles reinforced friction stir welded AA7075 and AA2024

Authors

- Pradeep Kumar Mouria

- Ranganath M. Singari

- Reeta Wattal

- Content type: Original Article

- Published: 18 December 2023

- Pages: 1331 - 1343

-

Dimensional accuracy and stability analysis of laser powder bed fusion (LPBF) samples: implications of process variables

Authors (first, second and last of 4)

- Meena Pant

- Girija Moona

- Harish Kumar

- Content type: Original Article

- Published: 16 December 2023

- Pages: 1121 - 1129

-

A structural model of Welding 4.0 implementation challenges

Authors (first, second and last of 4)

- Shailendra Kumar

- Khushboo Sharma

- Vijayant Maan

- Content type: Original Article

- Published: 12 December 2023

- Pages: 1243 - 1254

-

Modelling and mechanical properties evaluation for lap joint of natural composites using finite element method

Authors (first, second and last of 9)

- Phani Prasanthi

- Ch. Mohan Sumanth

- Sherzod Shukhratovich Abdullaev

- Content type: Original Article

- Published: 25 November 2023

- Pages: 1291 - 1302

-

Optimization parameters for electro discharge machining on Nimonic 80A alloy using grey relational analysis

Authors (first, second and last of 9)

- Maddipati Rajesh

- M. Naga Swapna Sri

- S. Vijayakumar

- Content type: Original Paper

- Published: 22 November 2023

- Pages: 1429 - 1442

-

Optimization of welding parameters and microstructure analysis of low frequency vibration assisted SMAW butt welded joints

Authors

- Rajeev Ranjan

- Sanjay Kumar Jha

- Content type: Original Paper

- Published: 20 October 2023

- Pages: 1687 - 1707

-

Investigation of mechanical, microstructural and corrosive properties of ERNiCrMo-3 – ERCuSiA based additively manufactured functionally graded material

Authors (first, second and last of 6)

- Tejendra Singh Singhal

- **esh Kumar Jain

- Kuldeep Kumar Saxena

- Content type: Original Paper

- Published: 11 October 2023

- Pages: 1195 - 1205

-

MIG welding process parameter optimisation of AISI 1026 steel using Taguchi-TOPSIS method

Authors (first, second and last of 9)

- Swati Sharma

- D. Anitha

- Sherzod Shukhratovich Abdullaev

- Content type: Original Paper

- Published: 09 October 2023

- Pages: 1345 - 1357

-

Multi-objective optimization using Taguchi based grey relational analysis in friction stir welding for dissimilar aluminium alloy

Authors (first, second and last of 9)

- Srikanth Karumuri

- Barun Haldar

- S. Vijayakumar

- Content type: Original Paper

- Published: 04 October 2023

- Pages: 1627 - 1644