Abstract

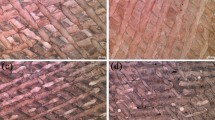

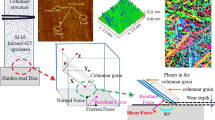

IN738C is a widely utilized precipitation hardening nickel-based superalloy known for its excellent mechanical properties in various industries. Laser powder bed fusion (LPBF) has emerged as a highly advantageous additive manufacturing process for fabricating complex-shaped parts using metal powders. This study investigates the influence of process parameters, specifically the scanning speed and hatch spacing, on the defect formation in LPBF-manufactured IN738C alloy. Additionally, the microstructure of heat-treated IN738C samples is examined, and their mechanical properties are evaluated through ambient tensile testing. The results indicate that LPBF-produced IN738C alloy exhibits the highest density when using a hatch spacing of 90 μm and a scanning speed of 750 mm/s. Upon heat treatment, cracks within the material propagated. Microscopic analysis of the heat-treated specimens reveals the presence of precipitated carbides and the 03B3′ phase, with continuous carbides observed along the grain boundaries. The as-built (AB) specimens exhibit a medium result in ultimate tensile strength (UTS), yield strength (YS), and elongation. However, the heat-treated (HT) specimens fail prior to yielding, exhibiting a lower result in UTS and elongation than AB specimens.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Mouritz, A.P.: Superalloys for Gas Turbine Engines, Introduction to Aerospace Materials, pp. 251–267 (2012)

Perrut, M., Caron, P., Thomas, M., Couret, A.: High temperature materials for aerospace applications: Ni-based superalloys and γ-TiAl alloys. Compt. Rendus Phys. 19(8), 657–671 (2018)

Han, Q., Gu, H., Soe, S., Setchi, R., Lacan, F., Hill, J.: Manufacturability of AlSi10Mg overhang structures fabricated by laser powder bed fusion. Mater. Des. 160, 1080–1095 (2018)

Ma, Y., Xu, J., Gao, Y., Liu, B., Hu, Y., Ding, Y., Chen, D., Chen, H.: Evolution and formation mechanism of defect in SLM-built inconel 738 alloy. Mater. Rep. 36(13), 166–172 (2022)

Yan, H., Zhu, G., Shi, H., Zhang, P., Li, H., Lu, Q., Li, Z.: Microstructure and mechanical properties of K438 alloy processed by selective laser melting and subsequent heat treatment. Mater. Charact. 191, 112116 (2022)

Guo, C., Zhou, Y., Li, X., Hu, X., Xu, Z., Dong, E., Zhu, Q., Ward, R.: A comparing study of defect generation in IN738LC superalloy fabricated by laser powder bed fusion: continuous-wave mode versus pulsed-wave mode. J. Mater. Sci. Technol. 90, 45–57 (2021)

Xu, J., Ding, Y., Gao, Y., Wang, H., Hu, Y., Zhang, D.: Grain refinement and crack inhibition of hard-to-weld Inconel 738 alloy by altering the scanning strategy during selective laser melting. Mater. Des. 209, 109940 (2021)

Zhang, Z., Han, Q., Liu, Z., Wang, X., Wang, L., Yang, X., Ma, T., Gao, Z.: Influence of the TiB2 content on the processability, microstructure and high-temperature tensile performance of a Ni-based superalloy by laser powder bed fusion. J. Alloy. Compd. 908, 164656 (2022)

Zhou, W., Tian, Y., Tan, Q., Qiao, S., Luo, H., Zhu, G., Shu, D., Sun, B.: Effect of carbon content on the microstructure, tensile properties and cracking susceptibility of IN738 superalloy processed by laser powder bed fusion. Addit. Manuf. 58, 103016 (2022)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Zhang, H., Han, Q., Liu, Z., Zhang, Z., Sui, Z., Wang, L. (2024). Microstructure and Mechanical Properties of IN738C Superalloy Fabricated by Laser Powder Bed Fusion. In: Scholz, S.G., Howlett, R.J., Setchi, R. (eds) Sustainable Design and Manufacturing 2023. SDM 2023. Smart Innovation, Systems and Technologies, vol 377. Springer, Singapore. https://doi.org/10.1007/978-981-99-8159-5_18

Download citation

DOI: https://doi.org/10.1007/978-981-99-8159-5_18

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-8158-8

Online ISBN: 978-981-99-8159-5

eBook Packages: EngineeringEngineering (R0)