Abstract

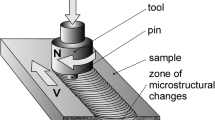

The use of magnesium in the automobile and biomedical applications is increasing nowadays due to its lightweight and high specific strength but magnesium alloys have some drawbacks like low ductility, low absolute strength at higher temperature, low hardness, etc. In this research, Friction stir processing (FSP) has been used for improving the hardness and microstructural properties of magnesium AZ31 alloy. The changes in the properties have been observed at different tool rotations (580, 850 and 1160 rpm). It has been found that the size of the grains is maximum for the as-received sample, and its average size lies in between 47 and 69 µm and size of grains is minimum for the FS processed samples at 850 rpm and its average grain size lies in between 0.75 and 1.1 µm. The FS processed samples at 850 rpm showed an approximate 33–37% increase in the hardness.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Eliezer, D., Aghion, E., Sam Froes, F.H.: Magnesium science, technology and applications. Adv. Eng. Mater. 5, 201–212 (1998)

Kulekci, M.: Magnesium and its alloys applications in automotive industry. Int. J. Adv. Manuf. Technol. 39, 851–865 (2008)

Mordike, B.L., Ebert, T.: Magnesium: Properties—applications—potential. Mater. Sci. Eng. 302, 37–45 (2001)

Babua, S.R., Pavithranb, S., Nithinb, M., Parameshwaranb, B.: Effect of tool shoulder diameter during friction stir processing of AZ31B alloy sheets of various thicknesses. In: Proceedings 2014 12th Global Congress on Manufacturing and Management, GCMM’14, pp. 800–809

Aghion, E., Bronfin, B., Eliezer, D.: The role of the magnesium industry in protecting the environment. J. Mater. Process. Technol. 117, 381–3855 (2001)

Cavaliere, M.P.: Friction stir processing of AM60B magnesium alloy sheets. Mater. Sci. Eng., A 462, 393–397 (2007)

Arora, H.S., Singh, H., Dhindaw, B.K.: Composite fabrication using friction stir processing—a review. Int. J. Adv. Manuf. Technol. 61, 1043 (2012)

Wang, C.Y., Chang, Y., Yang, J., Cao, W.Q., Dong, H., Wang, Y.D.: Work Hardening Behavior and Stability of Retained Austenite for Quenched and Partitioned Steels. J. Iron Steel Res. Int. 23, 130–137 (2016)

Sun, K., Shi, Y., Sun, Y.J., Chen, G.Q.: Microstructure and mechanical property of nano-SiCp reinforced high strength Mg bulk composites produced by friction stir processing. Mater. Sci. Eng., A 547, 32 (2012)

Kai, M., Horita, Z., Langdon, T.G.: Develo** grain refinement and superplasticity in a magnesium alloy processed by high-pressure torsion. Mater. Sci. Eng., A 488, 117–124 (2008)

Huo, Q., Yang, Sun H., Li, B., Qin, J., Wang, J.: Enhancement of tensile ductility and stretch formability of AZ31magnesium alloy sheet processed by cross-wavy bending. J. Alloys Compd. 581, 230–235 (2013)

Bharti, A., Tripathi, H.: Enhancement of fatigue life of TIG-welded joint by friction stir processing. In: Renewable Energy and its Innovative Technologies, pp. 51–59. Springer, Singapore (2018)

Perez-Prado, M.T., Valle, J.A., Ruano, O.R.: Grain refinement of Mg–Al–Zn alloys via accumulative roll bonding. Scripta Mater. 51, 1093–1097 (2004)

Asgari, H., Odeshi, A.G., Szpunar, J.A., Zeng, L.J., Olsson, E., Li, D.Y.: Effect of yttrium on the twinning and plastic deformation of AE magnesium alloy under ballistic impact. Mater. Sci. Eng., A 166 623, 10–21 (2015)

Ma, Z.Y., Sharma, S.R., Mishra, R.S.: Effect of multiple-pass friction stir processing on microstructure and tensile properties of a cast aluminum–silicon alloy. Scr Mater. 54, 1623–1626 (2006)

Azizieh, M., Kokabi, A.H., Abachi, P.: Effect of rotational speed and probe profile on microstructure and hardness of AZ31/Al2O3 nanocomposites fabricated by friction stir processing. Mater. Des. 32, 2034 (2011)

Wen, W., Kuaishe, W., Qiang, G., Nan, W.: Effect of friction stir processing on microstructure and mechanical properties of cast AZ31 magnesium alloy. Rare Metal Mater. Eng. 41, 1522–1526 (2012)

ASTM Standard E3-11, Standard Guide for Preparation of Metallographic Specimens

ASTM Standard E384, 2011e1, Standard Test Method for Knoop and Vickers Hardness of Materials, ASTM International

ASTM Standard E112, Standard Test Methods for Determining Average Grain Size

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Tripathi, H., Bharti, A., Vishal, A., Kumar, N. (2020). Effect of Tool Rotation on Microstructure and Hardness of AZ31 Mg Alloy Processed by FSP. In: Biswal, B., Sarkar, B., Mahanta, P. (eds) Advances in Mechanical Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-0124-1_61

Download citation

DOI: https://doi.org/10.1007/978-981-15-0124-1_61

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-0123-4

Online ISBN: 978-981-15-0124-1

eBook Packages: EngineeringEngineering (R0)