Abstract

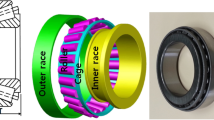

Needle roller bearing is one of the most widely used parts in transmission; however, it often fails due to wear. In order to investigate the mechanism of fatigue damage, the three-dimensional model based on the sixth shift needle roller bearing of a six-speed manual transmission was established with Romax Designer. Then, the distribution of the contact stresses on bearing raceways was simulated under different loads. It is found that the stress concentration caused by the deflection of the needle rollers will increase the contact stress and lead to the indentations on the raceway surface. The composite surface modification of the roller raceway was employed, and the loading cycle test was carried out on the transmission test rig. The results show that the composite surface modification technique can improve the fatigue intensity of the contact surface and effectively prevent the indentation. Relevant experimental results provide technical guidance and theoretical basis for the optimization of needle roller bearings’ raceway strength.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Chen LP (2005) Dynamics analysis of mechanical system and ADAMS application course[M]. Tsinghua University Press, Bei**g

Wei YG, Ge ZL, Jiang QY (2002) Finite element analysis of cylindrical rollers under nonuniform load used in shaft boxes bearings of high-speed vehicles and unsymmetric modification of the rollers. Lubr Eng 2:9–11

Zhang RT, Zhao YX, Cai H (2015) Skewed loading effect on the probalilistic lives of journal bearing of railway wagon. J Mech Eng 51(24):177–183

Mao YX, Shen XJ, Chen XY et al (2009) Study on contact stress distribution of roller bearings and roller profile design under misaligned loads. China Mech Eng 20(16):1918–1922

Chen XY, Zhou Y, Shen XJ et al (2015) Contact stress analysis and crowing design of friction pair with rollers under misalignment and skewing conditions. J South China Univ Technol (Nat Sci Ed) 6:77–83

Yang CH, Chen JB (2017) Analysis on eccentric load stress of tapered roller bearing in railway wagon. Bearing 5:9–11

Wang AL, Hong YF, Wang JG (2011) Analysis on contact of needle roller bearings. Bearing (11):1–4

Sun DC, Chen XY, Wang ZJ et al (2014) Numerical solution of the contact stress for load offsetting roller pairs based on fast fourier transform and conjugate method. Mach Des Manuf 11:43–46

Chen Y, Zang LB, Ju DY et al (2017) Research status and development trend on strengthening technology of high strength automobile gear surface. China Surf Eng 30(1):1–15

** H, Sakai M, Wu CL et al (1997) A study of the inhibitive effect of Mo on the temper softening of bearing surfaces caused by ion implantation. Wear 209(1–2):193–198

Wang Y (2004) Nano-and submicron-structured sulfide self-lubricating coatings produced by thermal spraying. Tribol Lett 17(2):165–168

Bouzakis KD, Vidakis N, Lontos A et al (2000) Implementation of low temperature-deposited coating fatigue parameters in commercial roller bearings catalogues. Surf Coat Technol 133:489–496

Lei S, Liu QK, Xue ZT et al (2009) Laser surface hardened layers for race surface of bearing rings. Bearing 10:30–33

Zhang XS, Wu Z (2000) Calculation of contact stress for mechanical components. Machinery 1:24–26

Xu K, Su JX, Zhou YD et al (2014) Theoretical formula and finite element analysis between gear pairs with line contact and point contact. J Mech Transm 8:77–81

Zhang LL, Gao X, Tan NL et al (2007) Simulation and analysis on rolling bearings based on ANSYS/LS-DYNA. J Mach Des 24(9):62–65

Shi MQ (2004) Study on multi-contacts with ADAMS. Comput Eng Appl 40(29):220–222

Zhang CB (2009) The studay of rolling contact fatigue failure and tests on super hard coating parts. Yanshan University

Acknowledgements

The authors would like to thank the National Key R&D Program of China (2017YFB0102400) and Innovation Project of Graduate Students of Hebei Province (CXZZBS2018036).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Chen, Y. et al. (2020). Analysis on Contact Strength of Needle Roller Bearing of Transmission and Effect of Surface Modification. In: (China SAE), C. (eds) Proceedings of China SAE Congress 2018: Selected Papers. SAE-China 2018. Lecture Notes in Electrical Engineering, vol 574. Springer, Singapore. https://doi.org/10.1007/978-981-13-9718-9_67

Download citation

DOI: https://doi.org/10.1007/978-981-13-9718-9_67

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-9717-2

Online ISBN: 978-981-13-9718-9

eBook Packages: EngineeringEngineering (R0)