Abstract

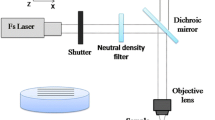

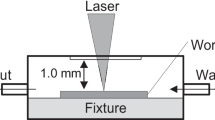

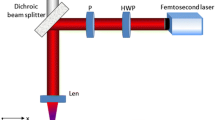

We have demonstrated a method for crack-free machining of groove in sapphire by using a CO2 continuous-wave (CW) laser under water. A sapphire wafer with a thickness of 1 mm is immersed into the water with 1 mm beneath the water surface. The effect of laser processing parameters on the jagged edge size and groove depth has been analyzed by tuning line-to-line spacing ranging from 0.006 to 0.1 mm as well as scanning speeds from 5 to 80 mm/s. As the decreasing of line-to-line spacing and the increasing of scanning speed, the jagged edge size reduces. The groove depth is deeper as the increasing of line-to-line spacing and scanning speed. Since underwater laser machining reduces substrate defects originated from heat accumulation from the laser, a groove without recast layer and cracking could be formed in sapphire wafer. The achieved groove in sapphire shows potential application for optical fiber sensing in harsh environments and microfluidic channels in corrosive solutions.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Griffin BA, Mills DA, Schmitz T, Sheplak M (2011) A sapphire based fiber optic dynamic pressure sensor for harsh environments: fabrication and characterization. In: 49th AIAA aerospace sciences meeting including the new horizons forum and aerospace exposition. AIAA, Orlando, FL, USA, pp 4–7

Yi J, Lally E, Wang A, Xu Y (2011) Demonstration of an all-sapphire Fabry–Pérot cavity for pressure sensing. IEEE Photon Technol Lett 23(1):9–11

Juodkazis S, Nishimura K, Misawa W (2007) In-bulk and surface structuring of sapphire by femtosecond pulses. Appl Surf Sci 253(15):6539–6544

Zhang W, Guo Y, Yan F, Gao T (2016) Study on thermodynamics damage characteristics of sapphire from CW Laser. Aero Weaponry 41(2):52–55

Yan Y, Li L, Sezer K, Wang W, Whitehead D, Ji L, Baob Y, Jiang Y (2011) CO2 laser underwater machining of deep grooves in alumina. J Euro Ceram Society 31(15):2793–2807

Acknowledgements

This project was funded by National Key Research and Development Program of China (2016YFF0100600); National Natural Science Foundation of China (Grants 61735009 and 61422507).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Huang, L., **ao, L., Pang, F., Liu, H., Zeng, X., Wang, T. (2021). Groove in Sapphire Machined by CO2 Laser Under Water. In: Xu, L., Zhou, L. (eds) Proceedings of the 8th International Multidisciplinary Conference on Optofluidics (IMCO 2018). IMCO 2018. Lecture Notes in Electrical Engineering, vol 531. Springer, Singapore. https://doi.org/10.1007/978-981-13-3381-1_6

Download citation

DOI: https://doi.org/10.1007/978-981-13-3381-1_6

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-3380-4

Online ISBN: 978-981-13-3381-1

eBook Packages: EngineeringEngineering (R0)