Abstract

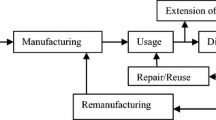

In recent years, the initiatives on sustainable business development have drawn significant attention by worldwide manufacturers especially for implementing remanufacturing strategies towards sustainable supply chain management. Sustainability term refers to the important trade-off decision making among economic, environmental and social responsibilities and roles through the value creation of commercial products and services. Remanufacturing strategies are currently considered as the viable post-use alternatives to a brand new product replacement. The post-use scenario consists of various operational processes, such as disassembling, inspecting, reprocessing, assembling, and testing when producing a remanufactured product. In this article, we presents an overview of the remanufacturing strategies towards sustainable supply chain management. A critical evaluation of assessment approaches with the practical implications is also discussed for future research.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Lin HW et al (2012) Design of a global decision support system for a manufacturing sme: towards participating in collaborative manufacturing. Int J Prod Econ 136(1):1–12

Kuik SS, Nagalingam SV, Amer Y (2012) Assessing sustainability in manufacturing using a fuzzy expert system. In: Third international conference on innovations in bio-inspired computing and applications (IBICA)

Kuik SS, Nagalingam, SV, Amer Y (2010) Challenges in implementing sustainable supply chain within a collaborative manufacturing network. In: 8th international conference on supply chain management and information systems (SCMIS)

Kuik SS, Kaihara T, Fujii N (2015) Stochastic decision model of the remanufactured product with warranty. In: Lecture notes in engineering and computer science: proceedings of the international multiconference of engineers and computer scientists, 18–20 March. 2015, Hong Kong, pp 1005–1010

Borsato M (2014) Bridging the gap between product lifecycle management and sustainability in manufacturing through ontology building. Comput Ind 65(2):258–269

Brandenburg M et al (2014) Quantitative models for sustainable supply chain management: developments and directions. Eur J Oper Res 233(2):299–312

Kuik SS, Nagalingam S, Amer Y (2011) Sustainable supply chain for collaborative manufacturing. J Manuf Technol Manage 22(8):984–1001

Nagalingam SV, Kuik SS, Amer Y (2013) Performance measurement of product returns with recovery for sustainable manufacturing. Robot Comput Integr Manuf 29(6):473–483

Craighill AL, Powell JC (1996) Lifecycle assessment and economic evaluation of recycling: a case study. Resour Conserv Recycl 17(2):75–96

Mangla S, Madaan J, Chan FS (2012) Analysis of performance focused variables for multi-objective flexible decision modeling approach of product recovery systems. Global J Flex Syst Manage 13(2):77–86

Gray C, Charter M (2006) Remanufacturing and product design, The Centre for Sustainable Design. University College for the Creative Arts, London, pp 1–77

Hu G, Bidanda B (2009) Modeling sustainable product lifecycle decision support systems. Int J Prod Econ 122(1):366–375

Johnson MR, McCarthy IP (2014) Product recovery decisions within the context of extended producer responsibility. J Eng Tech Manage 34:9–28

Das D, Dutta P (2013) A system dynamics framework for integrated reverse supply chain with three way recovery and product exchange policy. Comput Ind Eng 66(4):720–733

Erdos G, Kis T, **rouchakis P (2001) Modelling and evaluating product end-of-life options. Int J Prod Res 39(6):1203–1220

Vlachos D, Georgiadis P, Iakovou E (2007) A system dynamics model for dynamic capacity planning of remanufacturing in closed-loop supply chains. Comput Oper Res 34(2):367–394

Wan H-D, Krishna V (2013) Gonnuru, disassembly planning and sequencing for end-of-life products with RFID enriched information. Robot Comput Integr Manuf 29(3):112–118

Ziout A, Azab A, Atwan M (2014) A holistic approach for decision on selection of end-of-life products recovery options. J Clean Prod 65:497–516

Parlikad AK, McFarlane DC, Kulkarni AG (2006) Improving product recovery decisions through product information. In: Brissaud D, Tichkiewitch S, Zwolinski P (eds) Innovation in life cycle engineering and sustainable development. Springer, Netherlands, pp 153–172

Thabrew L, Ries R (2009) Application of life cycle thinking in multidisciplinary multistakeholder contexts for cross-sectoral planning and implementation of sustainable development projects. Integr Environ Assess Manage 5(3):445–460

Yamada T, Ohta N (2011) Modeling and design for reuse inverse manufacturing systems with product recovery values. In: Seliger G, Khraisheh MMK, Jawahir IS (eds) Advances in sustainable manufacturing, Springer, Berlin, pp 197–202

Godichaud M et al (2011) Sustainable management of end-of-life systems. Prod Plan Control 23(2–3):216–236

Ng YT, Lu WF, Song B (2014) Quantification of end-of-life product condition to support product recovery decision. Procedia CIRP 15:257–262

Croxton KL et al (2001) The supply chain management processes. Int J Logistics Manage 12(2):13–36

Wei C, Li Y, Cai X (2011) Robust optimal policies of production and inventory with uncertain returns and demand. Int J Prod Econ 134(2):357–367

Souza GC (2013) Closed-loop supply chains: a critical review, and future research*. Decis Sci 44(1):7–38

Madaan J, Kumar P, Chan FTS (2012) Decision and information interoperability for improving performance of product recovery systems. Decis Support Syst 53(3):448–457

Zhao Y et al (2010) Varying lifecycle lengths within a product take-back portfolio. J Mech Des 132(9):091012

Guide VD Jr et al (2008) The optimal disposition decision for product returns. Oper Manage Res 1(1):6–14

Gungor A, Gupta SM (1999) Issues in environmentally conscious manufacturing and product recovery: a survey. Comput Ind Eng 36(4):811–853

Chen C et al (2012) A new methodology for evaluating sustainable product design performance with two-stage network data envelopment analysis. Eur J Oper Res 221(2):348–359

Govindan K, Soleimani H, Kannan D (2015) Reverse logistics and closed-loop supply chain: a comprehensive review to explore the future. Eur J Oper Res 240(3):603–626

Hugo A, Pistikopoulos EN (2005) Environmentally conscious long-range planning and design of supply chain networks. J Clean Prod 13(15):1471–1491

Guo S, Aydin G, Souza GC (2014) Dismantle or remanufacture? Eur J Oper Res 233(3):580–583

Yang Q, Yu S, Jiang D (2014) A modular method of develo** an eco-product family considering the reusability and recyclability of customer products. J Clean Prod 64:254–265

Behdad S, Williams AS, Thurston D (2012) End-of-life decision making with uncertain product return quantity. J Mech Des 134(10):100902

Aickelin U (1999) Genetic algorithms for multiple choice optimisation problems. In School of computer science. University of Wales, London

Yeniay O (2005) Penalty function methods for contrained optimisation with genetic algorithm. Math Comput Appl 10(1):45–56

Yu S et al (2011) Product modular design incorporating life cycle issues—group genetic algorithm (GGA) based method. J Clean Prod 19(9–10):1016–1032

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer Science+Business Media Singapore

About this paper

Cite this paper

Kuik, S.S., Kaihara, T., Fujii, N. (2016). Remanufacturing Strategies for Sustainable Development. In: Yang, GC., Ao, SI., Huang, X., Castillo, O. (eds) Transactions on Engineering Technologies. Springer, Singapore. https://doi.org/10.1007/978-981-10-0551-0_13

Download citation

DOI: https://doi.org/10.1007/978-981-10-0551-0_13

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-0550-3

Online ISBN: 978-981-10-0551-0

eBook Packages: EngineeringEngineering (R0)