Abstract

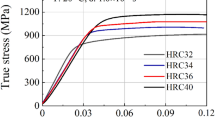

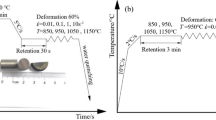

A finite volume computational method using Eulerian formulation to simulate forging is adopted in this paper. By means of this finite volume method, an approach based on the “metallo-thermo-mechanics” to simulate metallic structure, temperature and stress/strain coupled with strain-induced phase transformation has been developed. The material is considered as elastic-plastic and takes into account phase transformation effects on the yield stress. The temperature increase due to plastic deformation, heat conduction and thermal stress has been co-analyzed. Strain-induced phase transformation, latent heat, transformation stress and strain are included. The applicability of the developed method was confirmed through a backward extrusion. The strain rate dependence of the flow stress is formulated, and the effects of strain rate on the austenitic-martensite transformation and the aggregate flow stress are examined.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Angel, T. (1954). Formation of Martensite in Austenitic Stainless Steels — Effects of Deformation, Temperature, and Composition, J. Iron Steel Inst., 177, 165–174.

Cortes, R.J.A., Tsuta, T., Mitani, Y. and Osakada, K. (1992). Flow Stress and Phase Transformation Analysis in the Austenitic Stainless Steel under Cold Working — Part 1, Phase Transformation Characteristics and Constitutive Formulation by Energetic Criterion. JSME Int. J., 135, 201–209.

Cortes, R.J.A. and Tsuta, T. (1993). Flow Stress and Phase Transformation Analysis in the Austenitic Stainless Steel under Cold Working — Part 3, Analysis for SUS 301, SUS 304, SUS 310 Steels and Experiments on Forward and Backward Extrusions. Memoirs of the Faculty of Engineering, Hiroshima University, 11–3, 35–52.

Hecker, S.S., Stout, M.G., Staudhammer, K.P. and Smith, J.L. 1982). Effects of Strain and Strain Rate on Deformation-Induced Transformation in 304 Stainless Steel — Part I. Magnetic Measurements and Mechanical Behavior, Met. Trans., A 13A, 619–626.

Hirth, C. (1990). Numerical Computation of Internal and External Flows. Volume 2: Computational Methods for Inviscid and Viscous Flows, John Wiley & Sons.

Inoue, T., Nagaki, S., Kishino, T. and Monkawa, M. (1981). Description of Transformation Kinetics, Heat Conduction and Elastic-Plastic Stress in the Course of Quenching and Temperature of Some Steels. Ing.-Arch., 50, 315–327.

Ju, D.Y., Inoue, T. and Matsui, H. (1993). Visco-plastic Behavior of SUS-304 Stainless Steel at Ultra-high Temperature — Description by Unified Constitutive Models. In W.B. Lee (eds.), Advances in Engineering Plasticity and itsApplications, Elsevier Science Publishers, 521–528.

Kawai, N., Saiki, H. and Hirate, H. (1976). Improvement of Stretchability of 18–8 StainlessSteel Sheets due to Strain Induced Transformation. J. of the JSTP, 17, 899–906 (in Japanese).

Ludwigson, D.C. and Berger, J.A. (1969). Plastic Behavior of Metastable Austenitic Stainless Steels. J. of the Iron and Steel Inst., 207, 63–75.

Ohnaka, I. (1985). Introduction of Heat Transfer and Solidification Analysis — Application on Casting Process, Maruzen Publisher, (in Japanese).

Olson, G.B. and Cohen, M. (1975). Kinetics of Strain-Induced Martensitic Nucleation, Met. Trans., A 6A, 791–795.

Osakada, K. (1995). Stress, strain, temperature and defect generated in the material. In Japan Society of Technology Plasticity (eds.), Forging Technology — Toward Net Shape Product, Coruna Publishing Co., LTD., 66–147 (in Japanese).

Shinagawa, K., Nishikawa, H., Ishikawa, T. and Hosoi, Y. (1990). Deformation-Induced Martensitic Transformation in Type 304 Stainless Steel during Cold Upsetting. Iron and Steel, 3, 156–162 (in Japanese).

Slagter, W.J., Florie, C.J.L and Venis, A.C.J. (1999). Advances in Three Dimensional Forging Process Modeling. Proc. of the 15th National Conference on Manufacturing Research, 73–78.

Tomita, A., Harada, H. and Iwamoto, T. (1994). Numerical Simulation of Deformation Behavior of TRIP Steels. Trans. JSME, A 60, 166–173 (in Japanese).

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2003 Springer Science+Business Media Dordrecht

About this paper

Cite this paper

Ding, P.R., Inoue, T., Imatani, S., Ju, D.Y., de Vries, E. (2003). Forging Simulation incorporating Strain-Induced Phase Transformation using the Finite Volume Method. In: Miehe, C. (eds) IUTAM Symposium on Computational Mechanics of Solid Materials at Large Strains. Solid Mechanics and Its Applications, vol 108. Springer, Dordrecht. https://doi.org/10.1007/978-94-017-0297-3_42

Download citation

DOI: https://doi.org/10.1007/978-94-017-0297-3_42

Publisher Name: Springer, Dordrecht

Print ISBN: 978-90-481-6239-0

Online ISBN: 978-94-017-0297-3

eBook Packages: Springer Book Archive