Abstract

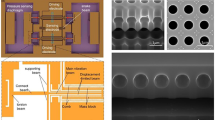

Most high volume applications of automotive pressure sensors have historically used some form of analog signal conditioning circuit to calibrate and compensate the silicon piezoresistive sensor element that has dominated many of these applications. This signal conditioning approach has often been implemented with some type of laser trimming to provide the appropriate circuit adjustments. Improvements on this approach have been introduced where electrical programming (e. g. fused links or nonvolatile memory) has been used to calibrate the circuit. However, even digital implementations of these calibration methods still rely on a core analog signal processor, thus providing only a discrete-analog solution to the sensor signal conditioning problem. This paper describes a monolithic pressure sensor integrated circuit that uses a custom, dedicated digital signal processor and nonvolatile memory to calibrate and temperature compensate a family of automotive pressure sensor modules for a wide range of applications. A specially developed digital communications interface permits calibration of a sensor module using the existing module connector pins after the module has been fully assembled and encapsulated. This approach eliminates any post-trim processing that could affect the sensor calibration. Module customization and calibration can be performed as an integral part of the end-of-line testing that is done at the completion of the sensor module manufacturing flow. Sub-micron CMOS circuit fabrication, bulk silicon micromachining, and wafer level bonding technology are uniquely combined to produce a cost-effective part which meets relevant automotive pressure sensor performance and durability criteria. Both digital and analog sensor outputs are available. This fully digital signal processing circuit provides programmable customer features and a significant degree of application flexibility without the system overhead and cost associated with a microprocessor implementation. It also provides a signal conditioning platform that can be applied to a variety of sensing technologies beyond just silicon piezoresistive pressure sensors.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Asano M, Kuma T, Kajitani M, Takeuchi M (1998). Development of New Ion Current Combustion Control System. SAE 980162

Balles E, VanDyne E, Wahl A, Ratton K, Lai M (1998). In-Cylinder Air/Fuel Ratio Approximation Using Spark Gap Ionization Sensing. SAE 980166

Gilkey J (1984). Fuel-Air Ratio Estimation From Cylinder Pressure in an Internal Combustion Engine. PhD Dissertation, Stanford University

Wibberly P, Clark C (1989). An Investigation of Cylinder Pressure as Feedback for Control of Internal Combustion Engines. SAE 890396

MIRA Engine Review (1997)

Krötz G, Wondrak W, Eickhoff M, Lauer V, Obermeier E, Cavalloni G (1997) New High-Temperature Sensors for Innovative Engine Management. AMAA 97, Springer-Verlag Berlin Heidelberg New York, pp. 223–230

Eickhoff M, Möller H, Krötz G, v. Berg J, Ziermann R (1998) A High Temperature Pressure Sensor Prepared by Selective Deposition of Cubic Silicon Carbide on SOI-Substrates. Paper presented at E-MRS Spring Meeting 1998 Strasbourg, France

Ziermann R, v. Berg J, Obermeier E, Eickhoff M, Krötz G (1997) A High Temperature Pressure Sensor With Beta-SiC Piezoresistors on SOI Substrates. Technical Digest International Conference on Solid-State Sensors and Actuators, Chicago, USA, p.1411

Hart M, Ziegler M, Loffeld O (1998) Adaptive Estimation of Cylinder Air Mass Using the Combustion Pressures. SAE 980791

Müller R, Hemberger H, Baier K, Gern T (1996) Control and Diagnostics in Automotive Applications. 96A4047

Müller R, Hemberger H (1998) Neural Adaptive Ignition Control. SAE 981057

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 1999 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Schuster, J.P., Czarnocki, W., Ding, X., Roeckner, B. (1999). Monolithic Pressure Sensor System with Digital Signal Processing. In: Ricken, D.E., Gessner, W. (eds) Advanced Microsystems for Automotive Applications 99. Springer and the environment. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-662-03838-3_27

Download citation

DOI: https://doi.org/10.1007/978-3-662-03838-3_27

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-662-03840-6

Online ISBN: 978-3-662-03838-3

eBook Packages: Springer Book Archive