Abstract

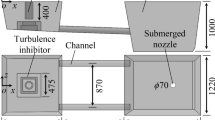

For high-temperature applications of a microreactor system the precise temperature control inside the reactor is important to optimize the yield of chemical reactions. If a microreactor system is operated inside a tube furnace, at best a homogeneous temperature distribution will be achieved inside the reactor. Heating elements that are integrated in the reactor have the potential to realize localized heating. Moreover, integrated heaters offer an efficient heating and a more convenient handling. Ohmic resistance heating for a modular ceramic microreactor system was investigated by direct connection and induction heating. The ceramic reactor system was modeled with FEM methods. Heat transfer and stress were calculated and compared with measurements taken.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Knitter R, Göhring D, Bram M, Mechnich P, Broucek R (2000) Ceramic Microreactor for High-Temperature Reactions. IMRET 4, 4th Int. Conf. on Microreaction Technology, AIChE Spring Meeting, March 5-9, Atlanta, Georgia, Topical Conference Proceedings 455–460.

Knitter R, Bauer W, Göhring D, Haußelt J (2001) Manufacturing of Ceramic Microcompo-nents by a Rapid Prototy** Process Chain. Adv. Eng. Mater. 3[1-2] 49–54.

Winter V, Knitter R (1997) Al2O3 /TiN as a Material for Micro Heaters. Micro Mat, 16.-18. April, Berlin, in: B. Michel, T. Winkler (eds.) Proceedings Micro Materials, ddp goldenbogen, Dresden, 1997, 1015–1017.

Stolz S, Bauer W, Ritzhaupt-Kleissl HJ, Haußelt J (2000) Ceramic Thick Films for Heating Applications. Electroceramics VII, 7th Int. Conf. on Electronic Ceramics and Their Applications, Portoroz, Slovenia, September 3-6, Abstract Book 222.

Murno R G (1997) Evaluated Material Properties for a sintered α-Alumina. J. Am. Ceram. Soc. 80[8] 1919–1928.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2001 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Knitter, R., Lurk, R., Rohde, M., Stolz, S., Winter, V. (2001). Heating Concepts for Ceramic Microreactors. In: Matlosz, M., Ehrfeld, W., Baselt, J.P. (eds) Microreaction Technology. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-56763-6_10

Download citation

DOI: https://doi.org/10.1007/978-3-642-56763-6_10

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-62706-4

Online ISBN: 978-3-642-56763-6

eBook Packages: Springer Book Archive