Abstract

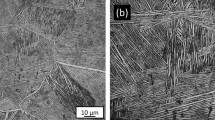

The hot workability of titanium alloy ingot is closely related to the morphology and size of initial grains. Based on the Gleeble thermal simulation experiment, the hot deformation behavior of equiaxed and columnar grains of Ti-6554 alloy ingot at deformation temperature of 950–1050 ℃ and strain rate of 0.01–1 s−1 was studied. The flow stress decreases with the increase of temperature or the decrease of strain rate. The strain modified Arrhenius constitutive model of equiaxed and columnar crystalline alloys was established by linear regression and polynomial fitting methods. And the predicted results were in good agreement with the experimental values. The results of microstructure evolution show that the density of grain boundary in unit volume of columnar crystal sample is higher. And the flow stress is greater than that of equiaxed crystal sample under the same deformation condition. With the increase of deformation temperature and the decrease of strain rate, the columnar crystal samples are more prone to DRX (dynamic recrystallization) than the equiaxed crystal samples. The equiaxed grains are transformed from serrated grain boundaries to bulged grain boundaries and regenerated into DRX grains. The columnar grains expands into a larger area of DRX region based on DRX strips or bulged grain boundaries.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Li, C.-M., et al.: Research progress on hot deformation behavior of high-strength β titanium alloy: flow behavior and constitutive model. Rare Met. 41(5), 1434–1455 (2022). https://doi.org/10.1007/s12598-021-01861-7

Huang, L., et al.: Research progress on microstructure evolution and hot processing maps of high strength β titanium alloys during hot deformation. Trans. Nonferrous Met. Soc. China 32(12), 3835–3859 (2022)

Li, C., Huang, L., Zhao, M., Guo, S., Li, J.: Study on microstructure evolution and deformation mechanism of Ti-6554 based on power dissipation efficiency at supertransus temperatures. J. Alloy. Compd. 924, 166481 (2022)

Yumak, N., Aslantaş, K.: A review on heat treatment efficiency in metastable β titanium alloys: the role of treatment process and parameters. J Mater Res Technol 9(6), 15360–15380 (2020)

Zhao, Q., et al.: High-strength titanium alloys for aerospace engineering applications: a review on melting-forging process. Mater. Sci. Eng. A 845, 143260 (2022)

Fan, X., Zhang, Y., Gao, P., Lei, Z., Zhan, M.: Deformation behavior and microstructure evolution during hot working of a coarse-grained Ti-5Al-5Mo-5V-3Cr-1Zr titanium alloy in beta phase field. Mater. Sci. Eng. A 694, 24–32 (2017)

Yang, Q., Ma, M., Tan, Y., **ang, S., Zhao, F., Liang, Y.: Initial β grain size effect on high-temperature flow behavior of Tb8 titanium alloys in single β phase field. Metals 9(8), 891 (2019)

Sarkar, A., Prasad, M.J.N.V., Murty, S.V.S.N.: Effect of initial grain size on hot deformation behaviour of Cu-Cr-Zr-Ti alloy. Mater. Charact. 160, 110112 (2020)

Babu, K.A., Mozumder, Y.H., Athreya, C.N., Sarma, V.S., Mandal, S.: Implication of initial grain size on DRX mechanism and grain refinement in super-304H SS in a wide range of strain rates during large-strain hot deformation. Mater. Sci. Eng. A 832, 142269 (2022)

Zhao, J., Wang, K., Lv, L., Liu, G.: Effect of grain size on the yield stress and microscopic mechanism of a near-α titanium alloy during non-superplastic hot deformation. Mater. Sci. Eng. A 840, 142932 (2022)

Wu, C., Huang, L.: Hot deformation and dynamic recrystallization of a near-beta titanium alloy in the β single phase region. Vacuum 156, 384–401 (2018)

Shi, S., Ge, J., Lin, Y.C., Zhang, X., Zhou, K.: High-temperature deformation behavior and recrystallization mechanism of a near beta titanium alloy Ti-55511 in β phase region. Mater. Sci. Eng. A 847, 143335 (2022)

Zhao, J., Zhong, J., Yan, F., Chai, F., Dargusch, M.: Deformation behaviour and mechanisms during hot compression at supertransus temperatures in Ti-10V-2Fe-3Al. J. Alloy. Compd. 710, 616–627 (2017)

Sellars, C.M., McTegart, W.J.: On the mechanism of hot deformation. Acta Metall. 14(9), 1136–1138 (1966)

Li, C., Huang, L., Zhao, M., Guo, S., Li, J.: Hot deformation behavior and mechanism of a new metastable β titanium alloy Ti-6Cr-5Mo-5V-4Al in single phase region. Mater. Sci. Eng. A 814, 141231 (2021)

Zhao, M., Huang, L., Li, C., Li, J., Li, P.: Evaluation of the deformation behaviors and hot workability of a high-strength low-alloy steel. Mater. Sci. Eng. A 810, 141031 (2021)

Li, C., Huang, L., Zhao, M., Zhang, X., Li, J., Li, P.: Influence of hot deformation on dynamic recrystallization behavior of 300M steel: rules and modeling. Mater. Sci. Eng. A 797, 139925 (2020)

Liu, W., et al.: Hot deformation behavior and new grain size model of hot extruded FGH4096 superalloy during hot compression. J. Alloy. Compd. 938, 168574 (2023)

Li, C., Huang, L., Zhao, M., Guo, S., Su, Y., Li, J.: Systematic analysis of the softening mechanism and texture evolution of Ti-6Cr-5Mo-5V-4Al alloy during hot compression in α+β phase region. Mater. Sci. Eng. A 850, 143571 (2022)

Zhao, M., Huang, L., Zeng, R., Su, H., Wen, D., Li, J.: In-situ observations and modeling of metadynamic recrystallization in 300M steel. Mater. Charact. 159, 109997 (2020)

Zhao, M., Huang, L., Zeng, R., Wen, D., Su, H., Li, J.: In-situ observations and modeling of static recrystallization in 300 M steel. Mater. Sci. Eng. A 765, 138300 (2019)

Zeng, R., Huang, L., Li, J., Li, H., Zhu, H., Zhang, X.: Quantification of multiple softening processes occurring during multi-stage thermoforming of high-strength steel. Int. J. Plast. 120, 64–87 (2019)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Guo, S., Huang, L., Li, C., Li, J. (2024). Hot Deformation Behavior of As-Cast Ti-6554 Alloy with Different Grain Morphologies. In: Mocellin, K., Bouchard, PO., Bigot, R., Balan, T. (eds) Proceedings of the 14th International Conference on the Technology of Plasticity - Current Trends in the Technology of Plasticity. ICTP 2023. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-41341-4_71

Download citation

DOI: https://doi.org/10.1007/978-3-031-41341-4_71

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-41340-7

Online ISBN: 978-3-031-41341-4

eBook Packages: EngineeringEngineering (R0)