Abstract.

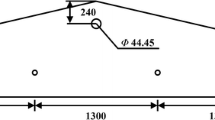

The empirical relations that govern multiphase interactions between microbubbles and inclusions indicate a strong dependence between bubble size and overall inclusion capture efficacy. Established probability models highlight the need for bubbles less than 1 mm in diameter for optimal inclusion capture. To achieve bubbles in this size regime, tangential shearing flows and turbulence can be used to facilitate bubble formation and fragmentation. A novel set-up consisting of nozzles submerged within a melt or an aqueous bath analog has been designed, manufactured, and operated, to test the bubble sizes produced for different speeds of rotation and effluent gas flow rates. Increasing gas flow rates lead to larger bubbles, whereas larger RPMs lead to much smaller bubble sizes. Bubbles are captured through high-speed digital photography and then analyzed using ImageJ postprocessing software. All experiments were conducted in an aqueous medium.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Lopez-Urunuela FJ, Fernandez-Diaz B, Pagano F, Lopez-Ortega A, Pinedo B, Bayon R, Aguirrebeitia J. Broad review of “White Etching Crack” failure in wind turbine gearbox bearings: Main factors and experimental investigations. Int J Fatigue. 2021;145(106091):106091. https://doi.org/10.1016/j.ijfatigue.2020.106091.

Jean-Pierre B. Steel cleanliness and environmental metallurgy. Metal Res Technol. 2016;113(2):201. https://doi.org/10.1051/metal/2015050.

Satyendra. Steel cleanliness and clean steel technologies; 2020. https://www.ispatguru.com/steel-cleanliness-and-clean-steel-technologies/. Last accessed 07 Feb 2022.

Pretorius EB, Oltmann HG, Schart BT. An overview of steel cleanliness from an industry perspective. AIST Trans. 2015;12(3)

Zhang L, Thomas BG, Wang X, Cai K. Evaluation and control of steel cleanliness review. In: 85th steelmaking conference. Warrendale: ISS-AIME; 2002. p. 431–52.

Chang S, Cao X, Hsin C-H, Zou Z, Isac MM, RlL G. Removal of inclusions using micro-bubble swarms in a four-strand, full-scale, water model tundish. ISIJ Int. 2016;56(7):1188–97. https://doi.org/10.2355/isi**ternational.ISIJINT-2016-077.

Lai Q, Luo Z, Hou Q, Zhang T, Wang X, Zou Z. Numerical study of inclusion removal in steel continuous casting mold considering interactions between bubbles and inclusions. ISIJ Int. 2018;58(11):2062–70. https://doi.org/10.2355/isi**ternational.ISIJINT-2018-319.

Marshall S, Chudacek MW, Bagster DF. A model for bubble formation from an orifice with liquid cross-flow. Chem Eng Sci. 1993;48(11):2049–59.

ANSYS Fluent User's Guide. https://www.scribd.com/document/357077969/ANSYS-Fluent-Users-Guide-pdf. Last accessed 18 Feb 2022.

Hirt C, Nichols B. Volume of fluid method for the dynamics of free boundaries. J Comput Phys. 1981;39:201–25.

Katopodes ND. Chapter 12 – Volume of fluid method. In: Free-surface flow. Oxford: Butterworth-Heinemann; 2019. p. 766–802.

Chang S, Huang W, Zou Z, Li B, RlL G. Motion behavior of micro-bubbles in a delta shape tundish using impact pad. Powder Technol. 2020;367:296–304.

Launder BE, Spalding DB. The numerical computation of turbulent flows. Comput Methods Appl Mech Eng. 1974;3:269–89.

Lalanne B, Masbernat O, Risso F. A model for drop and bubble breakup frequency based on turbulence spectra. Am Inst Chem Eng. 2019;65(1):347–59.

Sevik M, Park SH. The splitting of drops and bubbles by turbulent fluid flow. J Fluids Eng. 1973;95(1):53–60.

Martinez-Bazan C, Montanes JL, Lasheras J. On the breakup of an air bubble injected into a fully developed turbulent flow. I – breakup frequency. J Fluid Mech. 1999;401:157–82.

Acknowledgments

The authors acknowledge the financial support of NSERC, as well member companies of the McGill Metals Processing Centre, Rio Tinto Iron and Titanium, Nippon Steel Corporation, Japan, as well as Quebec Centre of Aluminum Research and Development.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Panicker, A., Lu, D., Tiwari, R., Calzado, L., Isac, M.M., Guthrie, R.I.L. (2023). A Novel Experimental Set-up for Generating Microbubbles for Removal of Inclusions. In: Proceedings of the 61st Conference of Metallurgists, COM 2022. COM 2022. Springer, Cham. https://doi.org/10.1007/978-3-031-17425-4_49

Download citation

DOI: https://doi.org/10.1007/978-3-031-17425-4_49

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-17424-7

Online ISBN: 978-3-031-17425-4

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)