Abstract

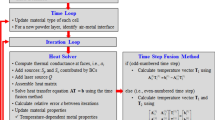

Additive manufacturing processes are driven by moving laser-induced thermal sources which induce strong heat fluxes and fronts of phase change coupled to mechanical fields. Their numerical simulation poses several challenges, e.g. the evolution of the (possibly complex) domain as the specimen is produced and the differences in scales of the problem. In this work, the first aspect is addressed using the Finite Cell Method, an immersed approach that removes the need for meshing and is able to accurately handle complex geometries. For the second aspect we develop a framework with local refinement to selectively increase accuracy where needed, and derefinement in previously refined regions far from the laser source to keep the overall computational cost constant throughout the simulation. In this work, we present the essential theoretical fundament of the computational framework. Then, we show its application to model additive manufacturing processes in various examples, including experimental validation.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

AM Bench Benchmark Challenge CHAL-AMB2018-02-MP (2018). https://www.nist.gov/ambench/amb2018-02-description

Special Metals Corporation (2018). http://www.speciametals.com

A. Abedian, A. Düster, Equivalent legendre polynomials: Numerical integration of discontinuous functions in the finite element methods. Comput. Methods Appl. Mech. Eng. 343, 690–720 (2019)

A. Abedian, J. Parvizian, A. Düster, H. Khademyzadeh, E. Rank, Performance of different integration schemes in facing discontinuities in the finite cell method. Int. J. Comput. Methods 10(03), 1350002 (2013)

M.I. Al Hamahmy, I. Deiab, Review and analysis of heat source models for additive manufacturing. Int. J. Adv. Manuf. Technol. 106(3-4), 1223–1238 (2020)

I. Babuška, B.A. Szabo, I.N. Katz, The \(p\)-version of the finite element method. SIAM J. Numer. Anal. 18, 515–545 (1981)

T. Bog, N. Zander, S. Kollmannsberger, E. Rank, Weak imposition of frictionless contact constraints on automatically recovered high-order, embedded interfaces using the finite cell method. Comput. Mech. 61(4), 385–407 (2018)

M. Carraturo, C. Giannelli, A. Reali, R. Vázquez, Suitably graded thb-spline refinement and coarsening: Towards an adaptive isogeometric analysis of additive manufacturing processes. Comput. Methods Appl. Mech. Eng. 348, 660–679 (2019)

M. Carraturo, J. Jomo, S. Kollmannsberger, A. Reali, F. Auricchio, E. Rank, Modeling and experimental validation of an immersed thermo-mechanical part-scale analysis for laser powder bed fusion processes. Additive Manuf. 36(2020). https://doi.org/10.1016/j.addma.2020.101498

D. Celentano, E. Oñate, S. Oller, A temperature-based formulation for finite element analysis of generalized phase-change problems. Int. J. Numer. Meth. Eng. 37(20), 3441–3465 (1994)

B. Cheng, S. Price, J. Lydon, K. Cooper, K. Chou, On process temperature in powder-bed electron beam additive manufacturing: model development and validation. J. Manuf. Sci. Eng. 136(6), 061018 (2014)

M. Chiumenti, X. Lin, M. Cervera, W. Lei, Y. Zheng, W. Huang, Numerical simulation and experimental calibration of additive manufacturing by blown powder technology. Part I: thermal analysis. Rapid Protot J 23(2), 448–463 (2017)

M. Chiumenti, E. Neiva, E. Salsi, M. Cervera, S. Badia, J. Moya, Z. Chen, C. Lee, C. Davies, Numerical modelling and experimental validation in Selective Laser Melting. Addit. Manuf. 18, 171–185 (2017)

J.A. Cottrell, T.J.R. Hughes, Y. Bazilevs, Isogeometric analysis: Towards Integration of CAD and FEM (Wiley, 2009)

D. D’Angella, S. Kollmannsberger, E. Rank, A. Reali, Multi-level Bézier extraction for hierarchical local refinement of isogeometric analysis. Comput. Methods Appl. Mech. Eng. 328, 147–174 (2018)

D. D’Angella, A. Reali, Efficient extraction of hierarchical b-splines for local refinement and coarsening of isogeometric analysis. Comput. Methods Appl. Mech. Eng. 367, 113131 (2020)

D. D’Angella, N. Zander, S. Kollmannsberger, F. Frischmann, E. Rank, A. Schröder, A. Reali, Multi-level hp-adaptivity and explicit error estimation. Adv. Model. Simul. Eng. Sci. 3(1), 33 (2016)

M. Dauge, A. Düster, E. Rank, Theoretical and numerical investigation of the finite cell method. Technical Report hal-00850602, CCSD (2013)

E.R. Denlinger, J. Irwin, P. Michaleris, Thermomechanical Modeling of Additive Manufacturing Large Parts. J. Manuf. Sci. Eng. 136(6), 061007 (2014)

P. Di Stolfo, A. Düster, S. Kollmannsberger, E. Rank, A. Schröder, A posteriori error control for the finite cell method. PAMM 19(1), e201900419 (2019)

P. Di Stolfo, A. Rademacher, A. Schröder, Dual weighted residual error estimation for the finite cell method. J. Numer. Math. 27(2), 101–122 (2019)

A. Düster, J. Parvizian, Z. Yang, E. Rank, The finite cell method for three-dimensional problems of solid mechanics. Comput. Methods Appl. Mech. Eng. 197, 3768–3782 (2008)

A. Düster, O. Allix, Selective enrichment of moment fitting and application to cut finite elements and cells. Comput. Mech. 65(2), 429–450 (2020)

A. Düster, E. Rank, B.A. Szabó, The p-version of the finite element method and finite cell methods, in Encyclopedia of Computational Mechanics, vol. 2, ed. by E. Stein, R. Borst, T.J.R. Hughes (Wiley, Chichester, West Sussex, 2017), pp. 1–35

M. Elhaddad, N. Zander, T. Bog, L. Kudela, S. Kollmannsberger, J. Kirschke, T. Baum, M. Ruess, E. Rank, Multi-level \(hp\)-finite cell method for embedded interface problems with application in biomechanics. Int. J. Numer. Methods Biomed. Eng. 34(4), e2951 (2018)

D.R. Forsey, R.H. Bartels, Hierarchical B-spline Refinement, in Proceedings of the 15th Annual Conference on Computer Graphics and Interactive Techniques, SIGGRAPH ’88, pages 205–212, New York, NY, USA, 1988. ACM

S. Ghosh, L. Ma, N. Ofori-Opoku, J.E. Guyer, On the primary spacing and microsegregation of cellular dendrites in laser deposited Ni-Nb alloys. Modell. Simul. Mater. Sci. Eng. 25(6), 065002 (2017)

C. Giannelli, B. Jüttler, S.K. Kleiss, A. Mantzaflaris, B. Simeon, J. Špeh, THB-splines: An effective mathematical technology for adaptive refinement in geometric design and isogeometric analysis. Comput. Methods Appl. Mech. Eng. 299, 337–365 (2016)

C. Giannelli, B. Jüttler, H. Speleers, THB-splines: The truncated basis for hierarchical splines. Comput. Aided Geom. Des. 29(7), 485–498 (2012)

J. Goldak, A. Chakravarti, M. Bibby, A new finite element model for welding heat sources. Metall. Trans. B 15(2), 299–305 (1984)

M. Gouge, E. Denlinger, J. Irwin, C. Li, P. Michaleris, Experimental validation of thermo-mechanical part-scale modeling for laser powder bed fusion processes. Addit. Manuf. 29, 100771 (2019)

G. Greiner, K. Hormann. Interpolating and approximating scattered 3d-data with hierarchical tensor product b-splines, in In Surface Fitting and Multiresolution Methods (Vanderbilt University Press, 1997), pp. 163–172

J.C. Heigel, B.M. Lane, Measurement of the melt pool length during single scan tracks in a commercial laser powder bed fusion process. J. Manuf. Sci. Eng. 140(5) (2018)

S. Hubrich, P. Di Stolfo, L. Kudela, S. Kollmannsberger, E. Rank, A. Schrüder, A. Düster, Numerical integration of discontinuous functions: moment fitting and smart octree. Comput. Mech. 1–19 (2017). https://doi.org/10.1007/s00466-017-1441-0

S. Hubrich, A. Düster, Numerical integration for nonlinear problems of the finite cell method using an adaptive scheme based on moment fitting. Comput. Math. Appl. 77(7), 1983–1997 (2019)

S. Hubrich, M. Joulaian, P.D. Stolfo, A. Schröder, A. Düster, Efficient numerical integration of arbitrarily broken cells using the moment fitting approach. Pamm 16, 201–202 (2016)

L. Hug, S. Kollmannsberger, Z. Yosibash, E. Rank, A 3D benchmark problem for crack propagation in brittle fracture. Comput. Methods Appl. Mech. Eng. 364(2020). https://doi.org/10.1016/j.cma.2020.112905

T.J.R. Hughes, The Finite Element Method: Linear Static and Dynamic Finite Element Analysis (Dover Publications, 2000)

T.J.R. Hughes, J.A. Cottrell, Y. Bazilevs, Isogeometric analysis: CAD, finite elements, NURBS, exact geometry and mesh refinement. Comput. Methods Appl. Mech. Eng. 194, 4135–4195 (2005)

N. Keller, F. Neugebauer, H. Xu, V. Ploshikhin, Thermo-mechanical simulation of additive layer manufacturing of titanium aerospace structures, in Proceedings of the LightMAT Conference (2013)

T. Keller, G. Lindwall, S. Ghosh, L. Ma, B.M. Lane, F. Zhang, U.R. Kattner, E.A. Lass, J.C. Heigel, Y. Idell, Application of finite element, phase-field, and CALPHAD-based methods to additive manufacturing of Ni-based superalloys. Acta Mater. 139, 244–253 (2017)

S.A. Khairallah, A.T. Anderson, A. Rubenchik, W.E. King, Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater. 108, 36–45 (2016)

W.E. King, A.T. Anderson, R.M. Ferencz, N.E. Hodge, C. Kamath, S.A. Khairallah, A.M. Rubenchik, Laser powder bed fusion additive manufacturing of metals; physics, computational, and materials challenges. Appl. Phys. Rev. 2(4), 041304 (2015)

S. Kollmannsberger, A. Özcan, J. Baiges, M. Ruess, E. Rank, A. Reali, Parameter-free, weak imposition of Dirichlet boundary conditions and coupling of trimmed and non-conforming patches. Int. J. Numer. Meth. Eng. 101(9), 1–30 (2014)

S. Kollmannsberger, A. Özcan, M. Carraturo, N. Zander, E. Rank, A hierarchical computational model for moving thermal loads and phase changes with applications to selective laser melting. Comput. Math. Appl. 75(5), 1483–1497 (2018)

S. Kollmannsberger, M. Carraturo, A. Reali, F. Auricchio, Accurate prediction of melt pool shapes in laser powder bed fusion by the non-linear temperature equation including phase changes. Integrat. Mater. Manuf. Innov. 8(2), 167–177 (2019)

S. Kollmannsberger, D. D’Angella, E. Rank, W. Garhuom, S. Hubrich, A. Düster, P. D. Stolfo, A. Schrüder, Spline- and hp-basis functions of higher differentiability in the finite cell method. GAMM-Mitteilungen 0(0), e202000004 (2019)

N. Korshunova, J. Jomo, G. Lékó, D. Reznik, P. Balázs, S. Kollmannsberger, Image-based material characterization of complex microarchitectured additively manufactured structures (2019). ar**v:1912.07415

R. Kraft, Surface Fitting and Multiresolution Methods Adaptive and linearly independent multilevel B-splines. (Vanderbilt University Press, Nashville, 1997)

L. Kudela, S. Kollmannsberger, U. Almac, E. Rank, Direct structural analysis of domains defined by point clouds. Comput. Methods Appl. Mech. Eng. 358, 112581 (2020)

L. Kudela, N. Zander, T. Bog, S. Kollmannsberger, E. Rank, Efficient and accurate numerical quadrature for immersed boundary methods. Adv. Model. Simul. Eng. Sci. 2(1), 10 (2015)

L. Kudela, N. Zander, S. Kollmannsberger, E. Rank, Smart octrees: accurately integrating discontinuous functions in 3d. Comput. Methods Appl. Mech. Eng. (2016)

Y. Lee, W. Zhang, Modeling of heat transfer, fluid flow and solidification microstructure of nickel-base superalloy fabricated by laser powder bed fusion. Addit. Manuf. 12, 178–188 (2016)

C. Li, J. Liu, X. Fang, Y. Guo, Efficient predictive model of part distortion and residual stress in selective laser melting. Addit. Manuf. 17, 157–168 (2017)

X. Liang, Q. Chen, L. Cheng, D. Hayduke, A.C. To, Modified inherent strain method for efficient prediction of residual deformation in direct metal laser sintered components. Comput. Mech. 64(6), 1719–1733 (2019)

L.-E. Lindgren, Numerical modelling of welding. Comput. Methods Appl. Mech. Eng. 195(48–49), 6710–6736 (2006)

L.-E. Lindgren, A. Lundbäck, M. Fisk, R. Pederson, J. Andersson, Simulation of additive manufacturing using coupled constitutive and microstructure models. Addit. Manuf. 12, 144–158 (2016)

J. Liu, A.C. To, Quantitative texture prediction of epitaxial columnar grains in additive manufacturing using selective laser melting. Addit. Manuf. 16, 58–64 (2017)

A. Lundbäck, L.-E. Lindgren, Modelling of metal deposition. Finite Elem. Anal. Des. 47(10), 1169–1177 (2011)

N. Patil, D. Pal, H. Khalid Rafi, K. Zeng, A. Moreland, A. Hicks, D. Beeler, B. Stucker, A generalized feed forward dynamic adaptive mesh refinement and derefinement finite element framework for metal laser sintering-part i: formulation and algorithm development. J. Manuf. Sci. Eng. 137(4), 041001 (2015)

R.B. Patil, V. Yadava, Finite element analysis of temperature distribution in single metallic powder layer during metal laser sintering. Int. J. Mach. Tools Manuf. 47(7–8), 1069–1080 (2007)

M. Petö, F. Duvigneau, S. Eisenträger, Enhanced numerical integration scheme based on image-compression techniques: application to fictitious domain methods. Adv. Model. Simul. Eng. Sci. 7(1), 21 (2020)

P. Promoppatum, S.-C. Yao, P.C. Pistorius, A.D. Rollett, P.J. Coutts, F. Lia, R. Martukanitz, Numerical modeling and experimental validation of thermal history and microstructure for additive manufacturing of an Inconel 718 product. Progress in Additive Manufacturing (2018)

D. Riedlbauer, P. Steinmann, J. Mergheim, Thermomechanical finite element simulations of selective electron beam melting processes: performance considerations. Comput. Mech. 54(1), 109–122 (2014)

M. Ruess, D. Schillinger, Y. Bazilevs, V. Varduhn, E. Rank, Weakly enforced essential boundary conditions for NURBS-embedded and trimmed NURBS geometries on the basis of the finite cell method. Int. J. Numer. Meth. Eng. 95(10), 811–846 (2013)

D. Schillinger, M. Ruess, N. Zander, Y. Bazilevs, A. Düster, E. Rank, Small and large deformation analysis with the p- and B-spline versions of the finite cell method. Comput. Mech. 50, 445–478 (2012)

D. Schillinger, I. Harari, M.-C. Hsu, D. Kamensky, S.K.F. Stoter, Y. Yu, Y. Zhao, The non-symmetric Nitsche method for the parameter-free imposition of weak boundary and coupling conditions in immersed finite elements. Comput. Methods Appl. Mech. Eng. 309, 625–652 (2016)

E. Soylemez, High deposition rate approach of selective laser melting through defocused single bead experiments and thermal finite element analysis for Ti-6Al-4V. Addit. Manuf. 31, 100984 (2020)

P.D. Stolfo, A. Schröder, N. Zander, S. Kollmannsberger, An easy treatment of hanging nodes in hp-finite elements. Finite Elem. Anal. Des. 121, 101–117 (2016)

B. Szabó and I. Babuška, Finite Element Analysis (Wiley, 1991)

B. Wassermann, S. Kollmannsberger, T. Bog, E. Rank, From geometric design to numerical analysis: A direct approach using the finite cell method on constructive solid geometry. Comput. Methods Appl. Mech. Eng. 74(7), 1703–1726 (2017). High-Order Finite Element and Isogeometric Methods 2016

B. Wassermann, S. Kollmannsberger, S. Yin, S. Kudela, E. Rank, Integrating CAD and numerical analysis: “Dirty geometry’’ handling using the Finite Cell Method. Comput. Methods Appl. Mech. Eng. 351, 808–835 (2019)

Z. Yan, W. Liu, Z. Tang, X. Liu, N. Zhang, M. Li, H. Zhang, Review on thermal analysis in laser-based additive manufacturing. Opt. Laser Technol. 106, 427–441 (2018)

Y. Yang, M. Allen, T. London, V. Oancea, Residual strain predictions for a powder bed fusion inconel 625 single cantilever part. Integrat. Mater. Manuf. Innov. 8(3), 294–304 (2019)

N. Zander, T. Bog, M. Elhaddad, F. Frischmann, S. Kollmannsberger, E. Rank, The multi-level hp-method for three-dimensional problems: Dynamically changing high-order mesh refinement with arbitrary hanging nodes. Comput. Methods Appl. Mech. Eng. 310, 252–277 (2016)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Kollmannsberger, S., D’Angella, D., Carraturo, M., Reali, A., Auricchio, F., Rank, E. (2022). The Finite Cell Method for Simulation of Additive Manufacturing. In: Schröder, J., Wriggers, P. (eds) Non-standard Discretisation Methods in Solid Mechanics. Lecture Notes in Applied and Computational Mechanics, vol 98. Springer, Cham. https://doi.org/10.1007/978-3-030-92672-4_13

Download citation

DOI: https://doi.org/10.1007/978-3-030-92672-4_13

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-92671-7

Online ISBN: 978-3-030-92672-4

eBook Packages: EngineeringEngineering (R0)