Abstract

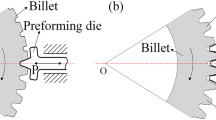

Spur gears are an important transmission part used widely in many industries. Precision forging of spur gears has a lot of advantages compared with the conventional mechanical cutting method. However, it is very difficult to fill the corner well and the forging load is also very large, especially in the final forming stage during the precision forging of spur gears. So, a three-dimensional (3D) finite element (FE) model for precision forging of spur gears was built by DEFORM-3D software. The stress and strain states in different forming stages and positions of billet have been studied. Also, the Lode parameter μσ was calculated, and the metal flow line method was used to reveal the deformation mechanism of the tooth material. Results show that the Lode parameter of the tooth shape is negative at the beginning of the tooth filling and is positive at the final stage of the tooth filling. Also, the stress state changes from two-directional compressive stress and one-directional tensile stress to three-directional compressive stress.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Kretzschmar J, Stockmann M, Ihlemann J, Schiller S, Hellfritzsch (2015) Experimental–numerical investigation of the rolling process of high gears. Exp Techniques 39(3):28–36

Feng W, Hua L, Han XH (2012) Finite element analysis and simulation for cold precision forging of a helical gear. J Cent South Univ 19:3369–3377

Wang Q, He F (2004) A review of developments in the forging of connecting rods in China. J Mater Proc Tech 151(1):192–195

Tuncer C, Dean TA (1987) Die design alternatives for precision forging hollow parts. Int J Mach Tools Manuf 27(1):65–76

Zuo B, Wang BY, Li Z, Zheng MN, Zhu XX (2015) Design of relief-cavity in closed-precision forging of gears. J Cent South Uni 22(4):1287–1297

Jung SY, Kang MC, Kim C, Kim CH, Chang YJ, Han SM (2009) A Study on the Extrusion by a two-step process for manufacturing helical gear. Int J Adv Manuf Technol 41(7–8):684–693

** ZY, Li NN, Zhang Q, Yan K, Cui ZS (2017) Effects of forging parameters on uniformity in deformation and microstructure of AZ31B straight spur gear. Trans Nonferrous Metals Soc China 27(10):2172–2180

Sadeghi MH (2003) Gear forging: mathematical modeling and experimental validation. J Manuf Sci Eng 125(4):753–762

Li F, Chu GN, Liu XJ (2009) Deformation division of metal flow behavior during extrusion process of 7075 aluminum alloy. J Cent South Univ Technol 16:0738–0742

Dunand M, Mohr D (2014) Effect of lode parameter on plastic flow localization after proportional loading at low stress triaxialities. J Mech Phys Solids 66:133–153

Zheng Y, Liu D, Zhang Z, Yang YH, Ren LJ (2017) The flow line evolution of hot open ACDG process for titanium alloy discs. Archives Civil Mech Eng 17:827–838

Feng W, Fu YH (2014) High temperature deformation behavior and constitutive modeling for 20CrMnTiH steel. Mater Des 57:465–471

Wang ZR (2006) The physical essence of Lode parameters and their influence on plastic flow. J Solid Mechan 27(3):277–282 (In Chinese)

Acknowledgments

The authors would like to thank the National Natural Science Foundation of China (51475344), 111 Project (B17034), and Innovative Research Team Development Program of the Ministry of Education of China (IRT13087) for the support given to this research.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Feng, W., Feng, Z., Zhou, M., Mao, L., Jia, X. (2021). Deformation Mechanism of the Tooth Material Filling for Precision Forging of Spur Gears. In: Daehn, G., Cao, J., Kinsey, B., Tekkaya, E., Vivek, A., Yoshida, Y. (eds) Forming the Future. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-75381-8_90

Download citation

DOI: https://doi.org/10.1007/978-3-030-75381-8_90

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-75380-1

Online ISBN: 978-3-030-75381-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)