Abstract

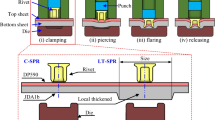

Duplex steel, aluminum alloy, carbon fiber-reinforced composites, and other materials have become the preferred lightweight materials for automobiles. The self-piercing riveted joints of dual-phase steel DP590 and aluminum alloy AA6061 were selected for fatigue tests, and the fatigue properties of the joints were analyzed. The typical fatigue failure fractures were observed by scanning electron microscopy (SEM), and the microfailure mechanism of the joints was analyzed. The results show that the fatigue properties of self-piercing riveted joints are different with different upper substrates. The failure modes of the AA35 joints are all fractures of the lower substrates. When the upper substrate is DP590 plate under high fatigue load, the cracks are easy to initiate in the rivet area. The cracks of the other self-piercing riveted joints originate on the side of the lower plate and extend along the riveted area to the width of the substrate.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Mori K-I, Abe Y (2018) A review on mechanical joining of aluminium and high strength steel sheets by plastic deformation. Int J Lightweight Mater Manuf 1(1):1–11

Huang ZC (2006) Progress in sheet metal joining technology. Forg Stamp Technol 4:119–122

Liu Y, He XC, **ng BY et al (2018) Fatigue properties and failure mechanisms of self-piercing riveted joints in metal form sandwich structures. Mater Rev 32(7):2431–2436

Rao HM, Kang J, Huff G et al (2018) Impact of specimen configuration on fatigue properties of self-piercing riveted aluminum to carbon fiber reinforced polymer composite. Int J Fatigue 113:11–22

Hirsch F, Müller S, Machens M et al (2017) Simulation of self-piercing rivetting processes in fibre reinforced polymers: material modelling and parameter identification. J Mater Process Tech 241:164–177

Ding WY, He XC, Liu JM et al (2018) Performance of self-pierce riveting based on carbon fiber reinforced polymer-AA5052 aluminum alloy three-layer sheets. Sci Technol Eng 18(25):143–147

Abe Y, Kato T, Mori K (2009) Self-piercing riveting of high tensile strength steel and aluminium alloy sheets using conventional rivet and die. J Mater Process Technol 209(8):3914–3922

** WH, **ng BY, He XC et al (2019) Failure behavior analysis of self-piercing riveted joints in steel-aluminum dissimilar metal under acid environment. Ordnance Mater Sci Eng 42(01):123–126

Chung CS, Kim HK (2016) Fatigue strength of self-piercing riveted joints in lap-shear specimens of aluminium and steel sheets. Fatigue Fract Eng Mater Struct 00:1–10

Zhao L, He X, **ng B et al (2017) Fretting behavior of self-piercing riveted joints in titanium sheet materials. J Mater Process Tech 249:246–254

**ng B, He X, Wang Y et al (2016) Fatigue properties and failure mechanisms of self-piercing riveted joints in aluminium alloy. Trans China Weld Inst (06):50–54 + 131

Gao ZT, Fu HM, Liang MX (1987) A method for fitting S-N curve. J Bei**g Inst Aeronaut Astronaut 1(1):115–119

Acknowledgments

This research is supported by the National Natural Science Foundation of China (51875201) and Key Research and Development Plan of Jiangxi Province (20192BBEL50013).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Huang, Z., Jia, Y., Lai, J. (2021). Fatigue Characteristics and Failure Mechanism of Self-piercing Riveted Joints of DP590 and AA6061 Plates. In: Daehn, G., Cao, J., Kinsey, B., Tekkaya, E., Vivek, A., Yoshida, Y. (eds) Forming the Future. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-75381-8_118

Download citation

DOI: https://doi.org/10.1007/978-3-030-75381-8_118

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-75380-1

Online ISBN: 978-3-030-75381-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)