Abstract

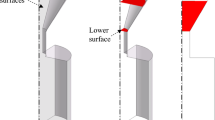

For the uneven gas–solid distribution in the process of fluidized bed ironmaking, the effect of the distributor on gas–solid homogeneity in fluidized bed was investigated by using physical simulation . Statistical analysis and spectral analysis were used to investigate the pressure fluctuations in the fluidized bed with the distributor of different perforated ratio , and the results were verified by optical analysis. The results reveal that the smaller perforated ratio of the distributor can reduce the bubble size of the whole bed and reduce the pressure fluctuation . Thus, the gas–solid dispersion is uniform, and the fluidization quality of the fluidized bed is improved. However, the distributor has a limited effect area, which has a great influence on the lower part of the fluidized bed . As the gas velocity and the height increase, the effect becomes weaker. Under the operating conditions of 100 L/min, the perforated ratio of 0.91% can reduce the pressure drop of the entire bed by 65%. It can also reduce the pressure drop deviation in the lower part of the bed by more than 79%.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Yun Y (2010) Theoretical calculation and cold state experimental study of fluidized ironmaking process. Northeastern University

Yun Y, Qiang L, Zongshu Z (2009) Design and research of cold state experiment of fluidized ironmaking process. Institute of Metallurgical Reaction Engineering, China Society of Metals, pp 566–575

Kuisong Z (2014) Cold model experiment and numerical simulation of iron ore powder bubbling fluidized bed. Chongqing University

Rahimpour F, Zarghami R et al (2017) Effect of distributor on fluidized bed hydrodynamics. Can J Chem Eng 95(11):2221–2234

Kim J, Han GY (2006) Effect of agitation on fluidization characteristics of fine particles in a fluidized bed. Powder Technol 166(3):113–122

Ren JQ, Mao QM, Li JH et al (2001) Wavelet analysis of dynamic behavior in fluidized beds. Chem Eng Sci 56(3):981–988

Zhang Y, Zhao Y, Liang D et al (2018) Flow pattern transition characteristics in vibrated gas-solid fluidized bed of Geldart B magnetite powder using pressure drop signals analysis. Powder Technol 327(3):358–367

Dong S, Cao C et al (2008) Effect of perforated ratio of distributor on the fluidization characteristics in a gas-solid fluidized bed. Chem React Eng Technol 48(1):517–527

Fan LT, Ho TC, Hiraoka S et al (1981) Pressure fluctuations in a fluidized bed. AIChE J 27(3):388–396

Baoliang L, Jianchun J, **fang Y et al (2007) Study on fluidization velocity of wood chips in cold bubbling fluidized bed. Chem Ind Ind 27(3):49–52

Luo Z, Zhao Y, Chen Q et al (2004) Effect of gas distributor on performance of dense phase high density fluidized bed for separation. Int J Miner Process 74(1):337–341

Liu M, Zhang Y, Bi H et al (2010) Non-intrusive determination of bubble size in a gas-solid fluidized bed: an evaluation. Chem Eng Sci 65(11):3485–3493

Dartonr C (1977) Bubble due to coalescence in fluidized beds. Trans Inst Chem Eng 55(3):134–140

Acknowledgements

This study was financially supported by the National Natural Science Fund Committee (U1760120), and the National Key R&D Program of China (2017YFC0210404, 2017YFC0210403-04).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Tao, W., Yan, L., **aolong, L., Xuejiao, C., Tingan, Z. (2020). Effect of Distributor Structure on the Uniformity of Multiphase System in Fluidized Ironmaking Process. In: Peng, Z., et al. 11th International Symposium on High-Temperature Metallurgical Processing. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-36540-0_59

Download citation

DOI: https://doi.org/10.1007/978-3-030-36540-0_59

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-36539-4

Online ISBN: 978-3-030-36540-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)