Abstract

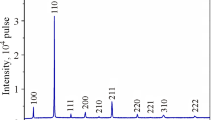

Fine, high purity alumina powders subjected to nominal plane strain shock conditioning in precompacted disc form by an explosively driven flyer plate were reconstituted as well-compacted specimens (DO = 0.65) and sintered dilatometrically in both CTS and RCS modes (Df = 0.98-0.99+). Effects of variations in precompaction and in shock velocity are characterized and related to sinterability, with emphasis on resultant temperatures at onset of shrinkage, initial stage densification kinetics, overall rate effects and microstruc- tural development.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

O. R. Bergmann and J. Barrington, J. Am. Ceram. Soc., 49, [9], 502 (1966).

A. C. Greenham and B. P. Richards, Trans. Brit. Ceram. Soc., 69, 115 (1970).

R. Prummer, Ber. Dtsch. Keram. Ges., 50 [3], 75–81 (1973).

R. Prummer and G. Ziegler, Powder Metall. Inst., 9, [1], 11–14 (1977).

S. Clyens and W. Johnson, Mat. Sci. Eng., 30, 121–29 (1977).

Dynamic Compaction of Metal and Ceramic Powders, National Materials Advisory Committee Study Report NMAB-394, National Research Council, October 1982.

H. Palmour III and D. R. Johnson, pp. 770–91 in Sintering and Related Phenomena, edited by G. C. Kuczynski, N. A. Hooton, and C. F. Gibbon, Gordon and Breach, NY, 1967.

M. L. Huckabee and H. Palmour III, am. Ceram. Soc. Bull., 49, [8], 574–76 (1972).

H. Palmour III and M. L. Huckabee, U.S. Patent 3,900,542, December 1, 1975.

H. Palmour III, M. L. Huckabee, and T. M. Hare, pp. 308–19 in Ceramic Microstructures — 76 76, edited by R. M. Fulrath and J. A. Pask, Westview Press, Boulder, CO, 1977.

T. M. Hare and H. Palmour III, pp. 307–20 in Ceramic Processing Before Firing, edited by G. Y. Onoda Jr. and L. L. Hench, John Wiley and Sons, NY, 1978.

H. Palmour III, M. L. Huckabee, and T. M. Hare, pp. 46–56 in Sintering — New Developments, edited by M. M. Ristic, Mat. Sci. Monographs, 4, Elsevier, Amsterdam, 1979.

M. L. Huckabee, T. M. Hare, and H. Palmour III, pp. 205–15 in Proceeding of Crystalline Ceramics, edited by H. Palmour III, R. F. Davis, and T. M. Hare, Mat. Sci. Res., Vol. 11, Plenum Press, NY, 1979.

H. Palmour III and M. L. Huckabee, pp. 278–97 in Factors in Densification and Sintering of Oxide and Non Oxide Ceramics, edited by S. Somiya, Assoc. for Sci. Doc. Info., Tokyo Inst, of Technology, Tokyo, Japan, 1979.

H. Palmour III and K. Y. Kim, Progress Rept. NCSU-82–01, Contract DAAK11–82-C-0040, June 1982.

H. Palmour III, K. Y. Kim, K. L. More, and R. C. Motley, pp. 331–72 in First Quarterly Report, DARPA Dynamic Synthesis and Consolidation Program, edited by C. L. Cline, Lawrence Livermore National Laboratory Report UCID — 19663, August 1982.

V. D. Linse, J. A. Adair, and R. Willis, pp. 1–79, Ibid.

H. Palmour III, T. M. Hare, J. C. Russ, A. D. Batchelor, M. J. Paisley, and L. J. Freed, Final Tech. Rept., Subcontract 6548901, University of California, Lawrence Livermore National Laboratory, September 1982.

A. D. Batchelor, M. J. Paisley, T. M. Hare, and H. Palmour III, this volume.

V. D. Linse (Battelle Columbus Laboratories), personal communication, 1982.

G. L. Moss (U.S. Army, Aberdeen Proving Ground), personal communication, 1982.

D. P. Dandekar (U.S. Army Mechanics and Materials Research Center), personal communication, 1982.

R. A. Graham (Sandia National Laboratory), personal communication, 1982.

G. K. Williamson and W. H. Hall, Acta Met., 1, 22 (1953).

C. S. Yust and L. A. Harris, pp. 881–94 in Shock Waves and High Strain Rate Phenomena in Metals, edited by M. A. Mayers and L. E. Murr, Plenum Press, NY, 1981.

C. L. Hoenig and C. S. Yust, Am. Ceram. Soc. Bull., 60 [11], 1175–76; 1121–24 (1981).

H. Palmour III, R. A. Bradley, and D. R. Johnson, pp. 392–407 in Kinetics of Reactions in Ionic Systems, edited by T. J. Gray and V. D. Frechette, Mat. Sci. Res., Vol. 4, Plenum Press, NY, 1969.

H. Palmour III, D. R. Johnson, C. H. Kim, and C. E. Zimmer, Tech. Rept. 69–5, Contract N00014–68-A-0187, 1969.

E. Beauchamp (Sandia National Laboratory), personal communication, 1982.

D. E. Peterson and F. W. Clinard, Jr., in Proceedings of Annual Meeting, Mat. Res. Soc., Boston, Nov. 1–5, 1982 (in press).

H. Palmour III, T. M. Hare, and M. L. Huckabee, Final Tech. Rept., Contract N00019–73-C-0139, March 1974;

H. Palmour III and T. M. Hare, Final Tech. Rept., Contract N00019–74-C-0265, July 1975.

H. Palmour III, V. D. Linse, and R. M. Spriggs, pp. 611–18 in Sintering — Theory and Practice, edited by D. Kolar, S. Pejovnik, and M. M. Ristic, Elsevier, Amsterdam, 1982.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 1984 Plenum Press, New York

About this chapter

Cite this chapter

Kim, K.Y., Batchelor, A.D., More, K.L., Palmour, H. (1984). Rate Controlled Sintering of Explosively Shock-Conditioned Alumina Powders. In: Davis, R.F., Palmour, H., Porter, R.L. (eds) Emergent Process Methods for High-Technology Ceramics. Materials Science Research, vol 17. Springer, Boston, MA. https://doi.org/10.1007/978-1-4684-8205-8_54

Download citation

DOI: https://doi.org/10.1007/978-1-4684-8205-8_54

Publisher Name: Springer, Boston, MA

Print ISBN: 978-1-4684-8207-2

Online ISBN: 978-1-4684-8205-8

eBook Packages: Springer Book Archive