Abstract

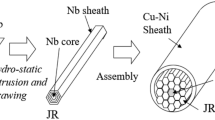

In the conventional bronze technique of manufacturing multifilamentary Nb3Sn superconducting wires (Fig. 1), a composite billet having niobium cores in a bronze sleeve is hot-extruded and drawn down to a rod. The number of filaments is increased by assembling these rods into a starting billet, which is again hot-extruded and drawn. After the cycles of assembly and reduction are completed, the rod is drawn down to a fine multifilamentary wire. Intermediate anneals must be given frequently to soften the bronze matrix. Finally, a diffusion anneal produces Nb3Sn at the niobium-bronze interface.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

J. Breme and C. H. Massat, The effect of hydrostatic extrusion on the superconducting characteristics of tin-bronze/niobium polymer conductors, Metallwiss. Tech. 33 (1979).

“Experimental Evaluation of Hydrostatic Extrusion for the Fabrication of Multifilamentary Superconducting Wire,” Report submitted by Battelle to the Division of Magnetic Fusion Energy, Energy Research and Development Administration (1976).

V. Thadani, B. Avitzur, Y. T. Chou, and T. Luhman, A comparison of hydrostatic extrusion versus wire drawing as a method of producing Nb3Sn superconducting wire, in: “9th NAMRC Proceedings,” SME, Dearborn (1981).

T. Luhman, M. Suenaga, D. O. Welch, and K. Kacho, Degradation mechanism of Nb3Sn composite wires under tensile strain at 4.2 K, IEEE Trans. Magn. MAG-15 (1979).

T. Luhman, Metallurgy of A15 conductors, in: “Treatise on Materials Science and Technology,” Vol. 14, T. Luhman and D. Hughes, eds., Academic Press, New York (1979).

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 1982 Plenum Press, New York

About this chapter

Cite this chapter

Thadani, V., Luhman, T.S., Avitzur, B., Chou, Y.T. (1982). Superconducting and Mechanical Properties of Cold Hydrostatically Extruded Monofilamentary Nb3Sn Wires. In: Reed, R.P., Clark, A.F. (eds) Advances in Cryogenic Engineering Materials . Advances in Cryogenic Engineering Materials , vol 28. Springer, Boston, MA. https://doi.org/10.1007/978-1-4613-3542-9_68

Download citation

DOI: https://doi.org/10.1007/978-1-4613-3542-9_68

Publisher Name: Springer, Boston, MA

Print ISBN: 978-1-4613-3544-3

Online ISBN: 978-1-4613-3542-9

eBook Packages: Springer Book Archive