Abstract

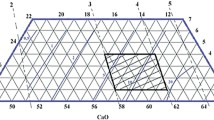

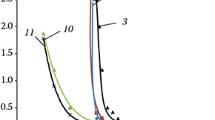

This paper describes theoretical and experimental studies of the dependence of the viscosity, coefficient of sulfur and boron distribution between slag and metal, as well as wear degree of periclase-carbon refractories on the basicity and boron oxide content in the slag. It is shown that the formed slags have the values of basicity from 2.0 to 5.0 and rather a high liquid mobility. These slags are characterized by an equilibrium interfacial distribution coefficient of sulfur increased to 5–20, which provides an equilibrium sulfur content in the metal reduced to 0.001–0.005%. The results of fundamental studies of the physical-chemical properties of refining slags of the CaO–SiO2–B2O3–Al2O3–MgO system formed the basis for development of the composition of environmentally friendly fluorine-free ladle slags and technological methods for their formation in the ladle-furnace unit. The recommended composition of such low-viscosity slags, which allow deep desulfurization, direct steel microalloying with boron, and a low aggressive effect on the periclase-carbon refractories, ensures formation of slags with a basicity of 3.0–4.0 containing 1–4% B2O3, 15% Al2O3, and 8% MgO. The formation of environmentally friendly ladle slags of the recommended composition was carried out in a ladle-furnace by loading lime, boron-containing material—colemanite (Turkey) containing 39–41% B2O3, 26–29% CaO, not more than 5% SiO2, and 3% MgO, and pyramidal aluminum into the steel-teeming ladle for slag deoxidation and boron recovery. Implementation of the developed technology for the formation of ladle slags with the recommended composition ensured production of economically alloyed low-carbon structural boron-containing steels with a low sulfur content, including for production of large-diameter pipes with high strength properties.

Similar content being viewed by others

REFERENCES

Dyudkin, D.A. and Kisilenko, V.V., Proizvodstvo stali (Steel Production), vol. 3: Vnepechnaya metalluriya stali (Extra-Furnace Metallurgy of Steel), Moscow: Teplotekhnik, 2010.

Chumakov S.M., Lamukhin A.M., Zinchenko S.D., et al., Concept of production of low-sulfur steels at JSC Severstal taking into account technological aspects, Trudy VI kongressa staleplavil’shchikov (Proceedings of the 6th Congress of Steelmakers), Moscow: Chermetinformatsiya, 2001, pp. 63–66.

Takahashi, D., Kamo, M., Kurose, Y., and Nomura, H., Deep steel desulphurisation technology in ladle furnace at KSC, Ironmaking Steelmaking, 2003, vol. 30, no. 2, pp. 116–119. https://doi.org/10.1179/030192303225001711

Akberdin, A.A., Kulikov, I.S., Kim, V.A., Nadyrbekov, A.K., and Kim, A.S., Fizicheskie svoistva rasplavov sistemy CaO–SiO 2 –Al 2 O 3 –MgO–CaF 2 (Physical Properties of the Melts of CaO–SiO2–Al2O3–MgO–CaF2 System, Moscow: Metallurgiya, 1987.

Wamg, H.-M., Li, G.-R., Dai, Q.-X., Li, B., Zhang, X.-J., and Shi, G.M., CAS-OB refining: Slag modification with B2O3–CaO and CaF2–CaO, Ironmaking Steelmaking, 2007, vol. 34, no. 4, pp. 350–353. https://doi.org/10.1179/174328107X155277

Ko, K.Y. and Park, J.H., Effect of CaF2 addition on the viscosity and structure of CaO–SiO2–MnO slags, ISIJ Int., 2013, vol. 53, no. 6, pp. 958–965. https://doi.org/10.2355/isi**ternational.53.958

Demin L.B., Sorokin Yu.V., Smirnov L.A., Shcherbakov E.N. Stabilization of decaying ferroalloy and steelmaking slags, Perspektivy razvitiya metallurgii i mashinostroeniya s ispol’zovaniem zavershennykh fundamental’nykh issledovanii in NIOKR. Trudy mezhdunarodnoi nauchno-prakticheskoi konferentsii (Prospects for the Development of Metallurgy and Mechanical Engineering using Completed Fundamental Research and R&D: Proceedings of the Int. Sci. and Pract. Conf.), Yekaterinburg: Al’fa Print, 2018, pp. 342–345.

Babenko A.A., Smirnov L.A., Upolovnikova A.G., and Smetannikov A.N., Development of composition of environmentally friendly fluorine-free slags of ladle steel metallurgy, Fundamental’nye issledovaniya i prikladnye razrabotki protsessov pererabotki i utilizatsii tekhnogennykh obrazovanii. Sbornik trudov V mezhdunarodnogo kongressa TEKhNOGEN-2021 (Fundamental Research and Applied Development of Processing and Utilization of Technogenic Formations: Proceedings of the 5th Int. Congress TECHNOGEN-2021), Yekaterinburg, 2021, pp. 349–350. https://doi.org/10.34923/technogen-ural.2021.39.62.123

Grabeklis, A.A., Demin, B.L., Kairakbaev, S.N., Musabekov, Zh.B., and Kavanov, B.O., Crystal-chemical stabilization of slags from refined-ferrochrome production, Steel Transl., 2010, vol. 40, pp. 479–484. https://doi.org/10.3103/S0967091210050153

Demin, B.L., Sorokin, Yu.V., Sharafutdinov, R.Ya., Murzin, A.V., and Zhilin, A.M., Testing the technology of crystal chemical stabilization of self-decaying steelmaking slags. Stal’, 2014, no. 6, pp. 102–106.

Akberdin, A.A., Kireeva, G.M., and Medvedovskaya, I.A., Effect of B2O3 on the viscosity of CaO–SiO2–Al2O3 slags, Izv. Akad. Nauk SSSR. Met., 1986, no. 3, pp. 55–56.

Hongming, W., Tingwang, Z., and Hua, Z., Effect of B2O3 on melting temperature, viscosity and desulfurization capacity of CaO-based refining flux, ISIJ Int., 2011, vol. 51, no. 5, pp. 702–706. https://doi.org/10.2355/isi**ternational.51.702

Zhang, L., Wang, W., **e, S., Zhang, K., and Sohn, I., Effect of basicity and B2O3 on the viscosity and structure of fluorine-free mold flux, J. Non-Cryst. Solids, 2017, vol. 460, pp. 113–118. https://doi.org/10.1016/j.jnoncrysol.2017.01.031

Benavidez, E., Santini, L., Valentini, M., and Brandaleze, E., Influence of different oxides on the viscosity of fluorine-free mold fluxes, Procedia Mater. Sci., 2012, vol. 1, pp. 389–396. https://doi.org/10.1016/j.mspro.2012.06.052

Li, W. and Xue, X., Effects of Na2O and B2O3 addition on viscosity and electrical conductivity of CaO–Al2O3–MgO–SiO2 system, ISIJ Int., 2018, vol. 58, no. 10, pp. 1751–1760. https://doi.org/10.2355/isi**ternational.ISIJINT-2018-212

Liu, L.X., Wang, G., Wang, Sh.J., Dong, Y.C., and Chai, Y.F., Calculation of phase diagram of CaO–SiO2–Al2O3–MgO–B2O3 refining slag without CaF2, Adv. Mater. Res., 2012, vols. 512–515, pp. 1558–1563. doi 10.4028/www.scientific.net/AMR.512-515.1558

Babenko, A.A., Shartdinov, R.R., Upolovnikova, A.G., Smetannikov, A.N., and Mikhailova, L.Yu., Effect of basicity and chromium oxide on the viscosity of boron-containing slags, IOP Conf. Ser.: Mater. Sci. Eng., 2020, vol. 966, p. 012012. https://doi.org/10.1088/1757-899X/966/1/012012

Kim, V.A., Nikolai, E.N., Akberdin, A.A., and Kulikov, I.S., Planirovanie eksperimenta pri issledovanii fiziko-khimicheskikh svoisv metallurgicheskikh shlakov (Planning an Experiment in Research of Physico-Chemical Properties of Metallurgical Slags), Alma-Ata: Nauka, 1989.

Babenko, A.A., Smirnov, L.A., and Upolovnikova, A.G., Equilibrium boron distribution between Fe–C–Si–Al melt and boron-bearing slag, J. Int. Sci. Publ.: Mater., Methods Technol., 2018, no. 12, pp. 202–208.

Babenko, A.A., Smirnov, L.A., and Upolovnikova, A.G., Theoretical and experimental studies of sulfur and boron distribution between the slag of the CaO–SiO2–B2O3–MgO– Al2O3 system and the metal, Defect Diffusion Forum, 2021, vol. 410, pp. 287–292. doi 10.4028/www.scientific.net/DDF.410.287

Babenko, A.A., Smirnov, L.A., and Upolovnikova, A.G., Fundamental research as a basis for the creation of new technologies in steel ladle metallurgy, Mater. Sci. Forum, 2019, vol. 946, pp. 493–499. doi 10.4028/www.scientific.net/MSF.946.493

Arsent’ev, P.P., Yakovlev, V.V., and Krasheninnikov, M.G., et al., Fiziko-khimicheskie metody issledovaniya metallurgicheskikh protsessov. Uchebnik dlya vuzov (Physicochemical Methods of Metallurgical Processes Research: Textbook for Universities), Moscow: Metallurgiya, 1988.

Funding

This work was supported by the state task of the Institute of Metallurgy of the Ural Branch of the Russian Academy of Sciences.

Author information

Authors and Affiliations

Contributions

A.A. Babenko, I.A. Smirnov, and E.V. Protopopov performed analysis and corrected the paper. A.G. Upolovnikova carried out thermodynamical calculations and wrote the paper, A.N. Smetannikov plotted diagrams, wrote and designed the paper.

Corresponding authors

Ethics declarations

CONFLICT OF INTEREST

The authors declare that they have no conflicts of interest.

INFORMATION ABOUT THE AUTHORS

Anatolii A. Babenko, Dr. Sci. (Eng.), Leading Researcher of the Laboratory of Steel and Ferroalloys, Institute of Metallurgy, Ural Branch of the Russian Academy of Sciences.

Leonid A. Smirnov, Academician, Dr. Sci. (Eng.), Leading Researcher of the Laboratory of Steel and Ferroalloys, Institute of Metallurgy, Ural Branch of the Russian Academy of Sciences.

Evgenii V. Protopopov, Dr. Sci. (Eng.), Prof. of the Chair of Ferrous Metallurgy, Siberian State Industrial University.

Alena G. Upolovnikova, Cand. Sci. (Eng.), Senior Researcher of the Laboratory of Steel and Ferroalloys, Institute of Metallurgy, Ural Branch of the Russian Academy of Sciences.

Artem N. Smetannikov, Junior Researcher of the Laboratory of Steel and Ferroalloys, Institute of Metallurgy, Ural Branch of the Russian Academy of Sciences.

SUPLEMENTARY INFORMATION

The online version contains supplementary material available at http://doi.org/10.3103/S096709122206002X

Additional information

Translated by E. Smirnova

About this article

Cite this article

Babenko, A.A., Smirnov, L.A., Protopopov, E.V. et al. Fundamental Studies of Physical-Mechanical Properties of Environmentally Friendly Fluorine-Free Slags and Their Use in Ladle Steel Industry. Steel Transl. 52, 568–573 (2022). https://doi.org/10.3103/S096709122206002X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S096709122206002X