Abstract

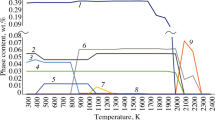

The expediency of producing and using complex ferroalloys in steelmaking is analyzed in terms the manufacturing technology, the raw materials employed, and the interactions of the ferroalloys with the molten steel. The need to produce complex ferroalloys with boron is established. The fundamental principles for determining the best composition of such alloys are presented. The basic compositions of complex ferroalloys with boron (ferrosilicomanganese with boron, ferrosilicon with boron, ferrosilicomanganese with boron and chromium) are established by studying the physicochemical properties of alloys and their interactions with the steel melt. If the characteristics (melting point, density, melting time of the ferroalloy in liquid steel, etc.) of complex ferroalloys with boron are compared with those of ferroboron, which is widely used, the complex alloys have clear benefits. The composition of the complex ferroalloys with boron includes active elements (Si, Al, Ti) facilitating the binding of oxygen and nitrogen from the steel melt in strong compounds and hence preventing their reaction with boron. The recommended boron content in the ferroalloy is 0.7–2%. That permits increase in the quantity of complex ferroalloys with boron in the steel and hence increase in the reliability and stability of boron assimilation. At elevated temperatures (1430–1570°C), the oxidation of ferrosilicoboron is 4–7 times less than that of ferroboron. Data are presented regarding the industrial production and use of ferrosilicoboron in the steel-smelting shop. The boron assimilation from complex alloys in microalloying of the steel is studied. The use of ferrosilicoboron does not require significant changes in the existing system for reduction by ferrosilicon; the boron assimilation is 77.8–96.3% (mean 86.6%). With a boron concentration of 0.0021–0.0027% in the steel during ladle treatment, its content in the cast metal will be no less than 0.0020%. If boron is introduced in steel by means of ferrosilicomanganese with boron, the boron assimilation is increased by a factor of 1.6 (from 48 to 77%, on average) in comparison with the use of ferroboron.

Similar content being viewed by others

References

Zhuchkov, V.I. and Mal’tsev, Yu.B., Physicochemical characteristics of new complex ferroalloys, in Fizicheskaya khimiya i tekhnologiya v metallurgii (Physical Chemistry and Technology in Metallurgy), Yekaterinburg: UrO RAN, 1996, pp. 131–144.

Zhuchkov, V.I., Selivanov, E.N., Sychev, A.V., Zayakin, O.V., and Babenko, A.A., Complex ferroalloys with boron for steel microalloying, Trudy mezhdunarodnoi konferentsii “Fiziko-khimicheskie osnovy metallurgicheskikh protsessov” (Proc. Int. Conf. “Physicochemical Principles of Metallurgical Processes”), Moscow: Inst. Metall. Materialoved., Ross. Akad. Nauk, 2012.

Parfenov, A.A., Topil’skii, A.V., and Druinskii, M.I., Suspension casting of FeSi-45, in Tekhnicheskii progress elektrometallurgii ferrosplavov (Technological Achievements in Ferroalloy Electrometallurgy), Dnepropetrovsk: Minist. Chern. Metall. UkrSSR, 1975, pp. 179–181.

Manashev, I.R., Shatokhin, I.N., Ziatdinov, M.Kh., and Bigeev, V.A., Microalloying of steel with boron and the development of ferrotitanium boride, Steel Transl., 2009, vol. 39, no. 10, pp. 896–900.

Heckmann, C.J., Ormston, D., and Grimpe, F., Development of low carbon Nb–Ti–B microalloyed steels for high strength large diameter linepipe, Ironmaking Steelmaking, 2005, vol. 32, no. 4, pp. 337–371.

Upadhyaya, N., Pujara, M.G., Sakthivelb, T., Mallikaa, C., Lahab, K., and Kamachi Mudalia, U., Effect of addition of boron and nitrogen on the corrosion resistance of modified 9Cr–1Mo ferritic steel, Proc. Eng., 2014, vol. 86, pp. 606–614.

Zhang, Y.-L., Zhang, Y.-Y., Yang, F.-H., and Zhang, Z.-T., Effect of alloying elements (Sb, B) on recrystallization and oxidation of Mn-containing IF steel, Int. J. Iron Steel Res., 2013, vol. 20, no. 3, pp. 39–44.

Kyung, C.C., Dong, J.M., Yang, M.K., and Jae, S.L., Effect of niobium and titanium addition on the hot ductility of boron containing steel, Mater. Sci. Eng. A, 2011, vol. 528, pp. 3556–3561.

López-Chipres, E., Mejía, I., Maldonado, C., Bedolla-Jacuinde, A., El-Wahabi, M., and Cabrera, J.M., Hot flow behavior of boron microalloyed steels, Mater. Sci. Eng. A, 2008, vol. 480, nos. 1–2, pp. 49–55.

Stumpf, W. and Banks, K., The hot working characteristics of boron bearing and conventional low carbon steel, Mater. Sci. Eng. A, 2006, vol. 418. pp. 86–94.

Fujishiro, T., Hara, T., Terada, Y., Sakamoto, S., and Asahi, H., Application of B-added low carbon bainite steels to X80 UOE line pipe for ultra low temperature usage, ASME 2010 8th Int. Pipeline Conf., Calgary, New York: Am. Soc. Mech. Eng., 2009, vol. 2, pp. 377–382.

Ovchinnikov, D.V., Sofrygina, O.A., Zhukova, S.Yu., Pyshmintsev, I.Yu., and Bityukov, S.M., Influence of microalloying with boron on the structure and properties of high-strength oil pipe, Steel Transl., 2011, vol. 41, no. 4, pp. 356–360.

Bigeev, A.M. and Bigeev, V.A., Metallurgiya stali (Steel Metallurgy), Magnitogorsk: Magnitogorsk. Gos. Tekh. Univ., 2000.

Golubtsov, V.A., Teoriya i praktika vvedeniya dobavok v stal’ vne pechi (Theory and Practice of Additions in Steel Furnaces), Chelyabinsk, 2006.

Pilyushchenko, V.L., Vikhlevchuk, V.A., Pozhivanov, M.A., and Leporskii, S.V., Nauchnye i tekhnologicheskie osnovy mikrolegirovaniya stali (Scientific and Technological Basis of Microalloying of Steel), Moscow: Metallurgiya, 1994.

Lukin, S.V., Zhuchkov, V.I., and Vatolin, N.A., The surface tension, density and oxidation kinetic of Fe–Si–B alloys, J. Less-Common Met., 1979, vol. 67, pp. 399–405.

Kim, A.S., Zayakin, O.V., Akberdin, A.A., and Kontsevoi, Yu.V., Production and application of new complex boron-containing ferroalloys, Russ. Metall. (Engl. Transl.), 2010, vol. 2010, no. 12, pp. 1148–1150.

Zhuchkov, V.I. and Andreev, N.A., Development of new ferroalloys with chromium, Proc. XIV Int. Ferroalloys Congr. INFACON XIV, Kiev, Ukraine, May 31–June 4, 2015, Kyiv, 2015, vol. 2, pp. 407–413.

Potapov, A.I. and Semin, A.E., Technological features of steel alloying with boron, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2012, no. 9, pp. 68–69.

Sirotin, D.V., Effektivnost’ povysheniya kachestva stali za schet mikrolegirovaniya (Efficiency of Quality Improvement by Microalloyng), Yekaterinburg: Inst. Ekon., Ural. Otd., Ross. Akad. Nauk, 2013.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.I. Zhuchkov, O.V. Zayakin, L.I. Leont’ev, A.V. Sychev, I.N. Kel’, 2017, published in Izvestiya Vysshikh Uchebnykh Zavedenii, Chernaya Metallurgiya, 2017, No. 5, pp. 348–354.

About this article

Cite this article

Zhuchkov, V.I., Zayakin, O.V., Leont’ev, L.I. et al. Physicochemical characteristics, production and application of boron-bearing complex ferroalloys. Steel Transl. 47, 291–295 (2017). https://doi.org/10.3103/S0967091217050163

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091217050163