Abstract

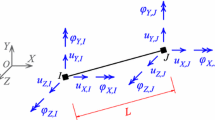

In this work, a finite element formulation is proposed to the analysis of flexible beams under plastic strains, ductile damage and plane-stress conditions. The novel feature of the study is the combination involving an any-order beam element transversely enriched and a Gurson’s porous plasticity theory together with nonlinear isotropic hardening, as well as void growth, nucleation and coalescence. The result is a high-order cross-sectional kinematics and a constitutive elastoplastic model with a competition between strain hardening and porosity-induced softening. The elastic prediction and plastic correction phases are employed together with the Newton-Raphson iterative scheme and the backward Euler time integration of the evolution equations.

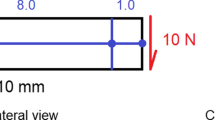

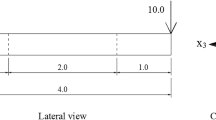

To validate the proposed formulation, a cantilever beam and a column under buckling are numerically analyzed. The influence of the mesh refinement, the set of elastoplastic parameters and the material model on the mechanical behavior is investigated in detail. High-order elements are preferable in terms of accuracy of results, despite their high computational effort regarding processing time and memory usage. Results show that the present model can reproduce finite deformations and through-the-thickness variation of 2D strains and stresses, as well as evolution of ductile damage. The importance of accounting for all the model features is also highlighted.

Similar content being viewed by others

REFERENCES

A. L. Gurson, “Continuum theory of ductile rupture by void nucleation and growth: Part I - Yield criteria and flow rules for porous ductile media,” J. Eng. Mater. Technol. 99 (4), 2–15 (1977). https://doi.org/10.1115/1.3443401

J. Lemaitre, “A continuous damage mechanics model for ductile fracture,” J. Eng. Mater. Technol. 107 (1), 83–89 (1985). https://doi.org/10.1115/1.3225775

V. Tvergaard and A. Needleman, “Analysis of the cup-cone fracture in a round tensile bar,” Acta Metall. 32 (1), 157–169 (1984). https://doi.org/10.1016/0001-6160(84)90213-X

G. Hütter, T. Linse, S. Roth, et al., “A modeling approach for the complete ductile–brittle transition region: cohesive zone in combination with a non-local Gurson-model,” Int. J. Fract. 185 (1), 129–153 (2014). https://doi.org/10.1007/s10704-013-9914-4

R. D. Thomson and J. W. Hancock, “Ductile failure by void nucleation, growth and coalescence,” Int. J. Fract. 26 (2), 99–112 (1984). https://doi.org/10.1007/BF01157547

X. P. Xu and A. Needleman, “Void nucleation by inclusion debonding in a crystal matrix,” Modell. Simul. Mater. Sci. Eng. 1 (2), 111 (1993). https://doi.org/10.1088/0965-0393/1/2/001

W. W. Pang, P. Zhang, G. C. Zhang, et al., “Dislocation creation and void nucleation in FCC ductile metals under tensile loading,” Sci. Rep. 4 (1), 1–7 (2014). https://doi.org/10.1038/srep06981

A. Needleman and V. Tvergaard, “An analysis of dynamic, ductile crack growth in a double edge cracked specimen,” Int. J. Fract. 49 (1), 41–67 (1991). https://doi.org/10.1007/BF00013502

K. L. Nielsen and V. Tvergaard, “Effect of a shear modified Gurson model on damage development in a FSW tensile specimen,” Int. J. Solids Struct. 46 (3–4), 587–601 (2009). https://doi.org/10.1016/j.ijsolstr.2008.09.011

J. P. Crété, P. Longère, and J. M. Cadou, “Numerical modelling of crack propagation in ductile materials combining the GTN model and X-FEM,” Comput. Methods Appl. Mech. Eng. 275, 204–233 (2014). https://doi.org/10.1016/j.cma.2014.03.007

F. Aldakheel, P. Wriggers, and C. Miehe, “A modified Gurson-type plasticity model at finite strains: formulation, numerical analysis and phase-field coupling,” Comput. Mech. 62 (4), 815–833 (2018). https://doi.org/10.1007/s00466-017-1530-0

J. P. Pascon and H. Waisman, “A thermodynamic framework to predict ductile damage in thermoviscoplastic porous metals,” Mech. Mater. 153, 103701 (2021). https://doi.org/10.1016/j.mechmat.2020.103701

M. A. R. K. Levinson, “A new rectangular beam theory,” J. Sound Vibr. 74 (1), 81–87 (1981). https://doi.org/10.1016/0022-460X(81)90493-4

J. N. Reddy, “A simple higher-order theory for laminated composite plates,” J. Appl. Mech. 51 (4), 745–752 (1984). https://doi.org/10.1115/1.3167719

S. A. Emam, “Analysis of shear-deformable composite beams in postbuckling,” Compos. Struct. 94 (1), 24–30 (2011). https://doi.org/10.1016/j.compstruct.2011.07.024

J. P. Pascon, “Finite element analysis of flexible functionally graded beams with variable Poisson’s ratio,” Eng. Comput. 33 (8), 2421–2447 (2016). https://doi.org/10.1108/EC-08-2015-0225

J. P. Pascon, “A new 2D beam finite element for nonlinear elastic analysis including war** and shear effects,” J. Brazil. Soc. Mech. Sci. Eng. 41 (6), 1–20 (2019). https://doi.org/10.1007/s40430-019-1760-5

S. Chandrakanth and P. C. Pandey, “Damage coupled elasto-plastic finite element analysis of a Timoshenko layered beam,” Comput. Struct. 69 (3), 411–420 (1998). https://doi.org/10.1016/S0045-7949(98)00116-3

A. Saritas, and F. C. Filippou, “Numerical integration of a class of 3d plastic-damage concrete models and condensation of 3d stress–strain relations for use in beam finite elements,” Eng. Struct. 31 (10), 2327–2336 (2009). https://doi.org/10.1016/j.engstruct.2009.05.005

M. Jukić, B. Brank, and A. Ibrahimbegovic, “Failure analysis of reinforced concrete frames by beam finite element that combines damage, plasticity and embedded discontinuity,” Eng. Struct. 75, 507–527 (2014). https://doi.org/10.1016/j.engstruct.2014.06.017

D. C. Feng, G. Wu, Z. Y. Sun, and J. G. Xu, “A flexure-shear Timoshenko fiber beam element based on softened damage-plasticity model,” Eng. Struct. 140, 483–497 (2017). https://doi.org/10.1016/j.engstruct.2017.02.066

P. K. Masjedi, A. Maheri, and P. M. Weaver, “Large deflection of functionally graded porous beams based on a geometrically exact theory with a fully intrinsic formulation,” Appl. Math. Modell. 76, 938–957 (2019). https://doi.org/10.1016/j.apm.2019.07.018

C. C. Chu and A. Needleman, “Void nucleation effects in biaxially stretched sheets,” J. Eng. Mater. Technol. 102 (3), 249–256 (1980). https://doi.org/10.1115/1.3224807

H. B. Coda and R. R. Paccola, “An alternative positional FEM formulation for geometrically non-linear analysis of shells: curved triangular isoparametric elements,” Comput. Mech. 40 (1), 185–200 (2007). https://doi.org/10.1007/s00466-006-0094-1

M. C. Oliveira, J. L. Alves, B. M. Chaparro, and L. F. Menezes, “Study on the influence of work-hardening modeling in springback prediction,” Int. J. Plasticity 23 (3), 516–543 (2007). https://doi.org/10.1016/j.ijplas.2006.07.003

Y. Li, J. He, B. Gu, and S. Li, “Identification of advanced constitutive model parameters through global optimization approach for DP780 steel sheet,” Proc. Eng. 207, 125–130 (2017). https://doi.org/10.1016/j.proeng.2017.10.749

I. A. R. Lopes, Master’s Dissertation (Faculdade de Engenharia da Universidade do Porto, Porto, 2013).

R. R. Paccola and H. B. Coda, AcadView 1.0 (Univ. of São Paulo, São Paulo, 2005).

Funding

The authors are thankful for all the support provided by the Lorena School of Engineering, of the University of São Paulo, including both Materials Engineering Department and Chemical Engineering Department.

Author information

Authors and Affiliations

Corresponding authors

About this article

Cite this article

Pascon, J., Daniel, V. A Finite Element Formulation for Highly Deformable Elastoplastic Beams Accounting for Ductile Damage and Plane Stress State. Mech. Solids 57, 1194–1213 (2022). https://doi.org/10.3103/S0025654422050119

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0025654422050119