Abstract

Systematic single-effect dissolution studies were carried out on the dissolution behaviour of pure and Cr- or Nd-doped UO2 reference pellets as model materials for spent nuclear fuel with varying do** levels, densities, and grain sizes as well as of industrially produced Cr- and Cr/Nd-doped UO2 pellets. The results were obtained from accelerated static batch dissolution experiments performed under strictly controlled conditions using H2O2 as simulant for radiolytic oxidants formed due to the alpha-irradiation of water. The results indicate that the addition of Cr and the consequential modification of the fuel matrix does not lead to a significant change of the dissolution behaviour of these model materials compared to pure UO2 reference materials. Contrarily, the dissolution rates of Nd-doped pellets are significantly lower than those of pure and Cr-doped pellets. These results provide additional insights into the influence of do** on the dissolution behaviour of modern spent light water reactor fuels under the post-closure conditions expected in a deep geological repository.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Due to the extremely high level of radioactivity of spent nuclear fuel (SNF), dominated by β- and γ-radiation, systematic experimental studies on mechanisms governing the long-term matrix corrosion of SNF are challenging [1]. The needs for extensive radiation shielding and remote handling, and the often limited amounts of SNF available for experimental studies allow generally only for a limited number of dissolution experiments. This hampers micro-analytical and micro-structural investigations of the materials prior and after dissolution experiments. Moreover, high-burn-up fuels or irradiated modern light water reactor (LWR) fuels doped, e.g., with Cr2O3 or Al2O3, are even less available so far for such experiments [2]. While the improved in-reactor performance of these fuels has already been demonstrated [3,4,5], their corrosion/dissolution behaviour in a deep geological repository (DGR) in comparison to conventional spent LWR-fuels is not completely understood. However, experiments with SNF cannot unravel all concurring processes effecting the dissolution mechanism in aqueous media, due to the chemical and structural complexity of SNF. In addition, “fresh” SNF is associated with a high α, β- and γ-radiation field. At the earliest time at which a failure of the waste container in a DGR is to be expected, SNF in a nominally reducing repository environment will come into contact with water and the radiation field will be dominated by α-radiation leading to water radiolysis [6,7,8,9,10,11]. Thus, complementary to experiments on doped SNF, dedicated dissolution studies are required using systematically produced and carefully characterised UO2-based model materials to understand the effects of the addition of Cr- or Ln3+-oxides into the fuel matrix on the SNF dissolution behaviour under conditions expected in a DGR post-closure. In this study, these model materials comprised (i) UO2 reference materials, and (ii) Cr- and Nd-doped UO2. Single-effect studies on the dissolution behaviour of the model materials provided complementary insights and supporting process understanding regarding the performance of modern doped fuels in the repository environment, which cannot be directly obtained from dissolution studies on SNF.

Materials and methods

Within this work no experiments on human and animal subjects are reported.

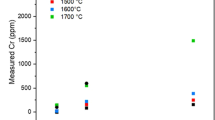

For all experiments chemicals with very high purity grade (99.9% or higher) were used and obtained from Merck, Emsure®, Sigma Aldrich and Honeywell Fluka. Previously degassed Millipore Milli-Q filtered water (18.2 MΩ resistivity, Elga PURELAB Ultra installation) was used throughout. The synthesis of the UO2 model materials with and without Cr- and Nd-do** for the dissolution experiments is described in detail in Kegler et al. [12] and is summarised only briefly here. The pure and the doped materials were synthesised using a (co-)precipitation method (CPM), where the metal ions in the desired mixture are quantitatively precipitated as pure or doped ammonium-diuranate (ADU). After several washing steps the dried ADU powder was calcined at 600 °C or 800 °C for 5 h in air to form U3O8. Subsequently U3O8 was reduced to UO2 in a second calcination step at 600 °C for another 5 h in reducing atmosphere (4% H2 in Ar). For samples doped with wet coating method (WCM) the dopant was added after this step and the previous steps of thermal treatment were repeated. Finally, the calcined powder was compacted to pellets and sintered at 1700 °C for 10 h in reducing atmosphere. No information is available about the preparation method of the commercially available Cr- and Cr/Nd-doped pellets (AREVA) used as reference industrial samples for the dissolution experiments in this work. A compilation of the samples and their properties is given in Table 1. The pellets used for the dissolution experiments have a diameter of approximately 8.5 mm and a thickness of approximately 1.5 mm, except the commercially available pellets purchased from AREVA (approx. 9.2 mm diameter, approx. 1.8 mm height). One site of the pellet was polished mirror like, whereas the other side was only grinded by a P1200 sandpaper (ISO designation, average grainsize 15.3 µm).

Accelerated dissolution experiments [7,8,9,10,11, 13] with UO2 model materials with and without Cr-do** synthesised in the framework of this work were carried out as static batch experiments in previously degassed bicarbonate solutions (NaHCO3, 10 mmol L−1), using hydrogen peroxide (H2O2, 2.25 mmol L−1) to mimic the oxidative radiolytic dissolution of UO2. A detailed description of the experimental procedure can be found in [13].

The experimental setup optimized for these dissolution experiments is shown in Fig. 1 and aimed in particular at (1) maintaining the pellets completely covered with test solution throughout the whole dissolution experiments, (2) allowing easy sampling of test solution and permanent flushing of the vessels with argon, (3) providing light tight vessels to ensure constant conditions regarding H2O2 degradation during the experiments, and (4) controlling the experimental temperature. During the experiment the temperature was kept constant at 22 °C.

The setup allows for the accomplishment of 11 dissolution experiments in parallel. The sample vessels were placed in a massive aluminium block equipped with a water conduit connected to a thermostat for temperature control. Plasticine gaskets were used to close the contact between the vessels and aluminium block and to ensure the light tightness of the vessels. To achieve anoxic conditions the solutions were flushed with argon during the complete experimental run time. In all experimental runs performed to date, 8 vessels were used for dissolution tests (Fig. 1a, blue gaskets) with UO2 based pellets, while 3 vessels were used as blanks to monitor the bulk degradation of H2O2 (Fig. 1a, red gaskets) which is needed for the later calculation of the dissolution yield. During the dissolution experiments, solutions were systematically sampled and the H2O2 (UV–Vis, Perkin Elmer, Lambda 19) and the uranium (ICP-MS, Perkin Elmer, NexION 2000) concentrations were determined.

The driving force for the UO2 dissolution in that kind of accelerated dissolution experiment is the oxidative potential of H2O2 which is proportional to its concentration in solution. In the experiments the NaHCO3 in the solution represents the bicarbonate contained in groundwater. It additionally serves the purpose to prevent the precipitation of U(+ VI) phases, and therefore, to ensure a reliable measurement of the uranium concentration in solution. Bicarbonate does not intervene directly in the oxidation process, but—with oxidative dissolution—complexes the dissolved U(+ VI) and thus influences the kinetics/driving force, so that the dissolution rate increases with the bicarbonate concentration [14]. Therefore, the NaHCO3 concentration was kept constant to 10 mmol L−1 in all experiments.

The end of the dissolution process is marked by the accomplishment of a constant uranium concentration in the solution. As stated before, this plateau is not due to the limit of U(+ VI) solubility, but due to the complete consumption of H2O2 in the solution. Due to the previously discovered surface passivation effect when repeatedly employing the same pellets in the dissolution tests, only results from dissolution experiments using pristine pellets were considered for determining the dissolution rates [13].

Results

The accelerated dissolution experiments in this work were conducted using pure, Cr- and Nd-doped UO2 pellets, as well as commercially available Cr- and Cr- plus Nd-doped UO2 pellets.

In Fig. 2 the uranium concentration in solution normalised to the geometrical surface area (a) and the H2O2 concentration (b) is plotted as a function of the first 300 h of dissolution experiments using pellets with different compositions. Red circles represent experiments with pure UO2, diamonds experiments using pellets doped with the wet coating method (representative for all Cr-doped UO2 pellets). The blue colour indicates that the samples used for the experiments were Cr-doped, green symbols represent Nd-do**. The yellow stars in Fig. 2b represent the H2O2 concentration in solution of a blank experiment.

a Uranium concentration in solution normalised to the geometrical pellet surface versus experimental duration. b H2O2 concentration in solution. The properties of the samples are listed in Table 1. Symbol code: circles—pure UO2 samples, squares—samples doped via co-precipitation method, diamonds—samples doped via wet coating method, triangles—commercially available samples, star—blank reactor (only H2O2). Colour code: red—pure UO2, blue—Cr-doped, green—Nd-doped, yellow—blank reactor (only H2O2)

All plots show a typical trend over time. Within the first 100 h, a significant increase of the uranium and decrease of the H2O2 concentration is evident (initial dissolution phase), while after 100 h the uranium and hydrogen peroxide concentration reach a constant value (steady state phase of the dissolution experiment). The initial dissolution phase is caused by preferred dissolution of highly activated surface sites of the pellets and the consumption of the hydrogen peroxide. Apparently, the dissolution is closely linked to the decrease of H2O2 due to the oxidation of U(+ IV) to U(+ VI) on the pellet’s surface. A comparison with the consumption of H2O2 in the blank experiment (yellow stars in Fig. 2b) shows a distinctly higher H2O2 consumption for experiments with UO2 pellets. This difference can be explained by the additional surface of the pellet, which is missing in the blank experiment, and by the oxidation from U(+ IV) to U(+ VI). The almost linearly decreasing H2O2 concentration in the blank experiment is caused by the decomposition of H2O2 and confirms that H2O2 is the driving force of the dissolution mechanism of UO2 in aqueous media. For most experiments the plateau after 100 h marks the end of these dissolution experiments because most of the hydrogen peroxide is consumed by the oxidation of UO2 or is decomposed (H2O2 concentration < 0.3 mmol L−1). The experiments with Cr-doped UO2 show no significant difference in the solution behaviour of uranium to the experiments conducted with pure UO2 pellets. The surface normalised uranium concentration in solution after accomplishment of the plateau is between 0.08 and 0.26 µmol L−1 mm−2. The mean initial dissolution rate for the experiments performed on pellets with and without Cr-do** is 1.24 ± 0.4·10–6 mol s−1 m−2 (RSD = 32.6%). The mean initial dissolution rate determined for the commercially available pellets are in good accordance with the values determined for pellets produced within this work. The distinct changes in the microstructure caused by Cr-do** (see Table 1) do not seem to have any significant influence on the dissolution behaviour of the UO2 matrix. Remarkably, in all experiments on Nd-bearing UO2 pellets significantly lower surface normalised uranium concentrations between 0.029 and 0.015 µmol L−1 mm−2 were detected after reaching the steady state plateau. The mean initial dissolution rate for these experiments is 1.63 ± 0.7 × 10–7 mol s−1 m−2 (RSD = 25.9%).

This effect is much better understandable if the dissolution yield is taken into account. The dissolution yield is the measure of the amount of H2O2 that oxidises U (+ IV) to U (+ VI) compared to the amount of H2O2 that decays at the sample surface in the same time period without oxidising uranium. It is estimated as the ratio of the amount of U(+ VI) dissolved from a pellet and the amount of H2O2 consumed on the same solid specimen. To determine this quantity, identical blank experiments without a sample must be performed in parallel with the dissolution experiments to determine the degradation of H2O2 at the surfaces in the experimental vessel. This amount of decayed H2O2 is subtracted from the determined H2O2 degradation in the experiment with sample to only consider the influence of the sample. With this quantity the efficiency of the oxidation process of U(+ IV) to U(+ VI) using H2O2 is expressed [15]. In Fig. 3 the dissolution yield is plotted as a function of the degree of initial do**.

The dissolution yields of the pure and the Cr-doped materials including the commercial pellet is mainly in the range between 0.7 and 3.0%. In contrast, the dissolution yield derived from the experiments with the Nd-doped samples (incl. the commercial pellet) is below 0.5%. This observation is underlined by the relatively high H2O2 concentration measured for the Nd-doped samples over the temporal evolution of the dissolution experiments (cf. Figure 2b green squares and green triangle). Apparently, much less H2O2 is consumed for the oxidation of UO2 due to do** with trivalent Nd3+ ions. It seems that the do** of Nd3+ is stabilising the UO2 structure and prevent U(+ IV) from oxidation [16].

Conclusion

The dissolution kinetics of pure, Cr- as well as Nd-doped UO2 pellets prepared by co-precipitation and wet-coating methods were investigated at room temperature in bicarbonate solutions using hydrogen peroxide to mimic the oxidative radiolytic dissolution of UO2. The investigations on these model systems show no evidence that the Cr-do** leads to a change in the dissolution behaviour i.e., normalised dissolution rates and yields of pure UO2 and Cr-doped UO2 pellets are in the same order of magnitude. In contrast, the Nd-doped UO2 pellets have a distinctly lower initial dissolution rates and yields which implies that less UO2 is oxidised in these samples. Apparently, Nd3+ is stabilising the UO2 structure. From these results it can be concluded that also do** of UO2 with Gd3+, which is used as burnable neutron poison in advanced nuclear fuels due to its very high neutron cross section, would probably lead to a comparable stabilisation of the UO2 like Nd3+, because of the very similar ionic radii and the chemical behaviour of both lanthanides [17, 18].

Data availability

The raw datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

D. Shoesmith: in Uranium: Cradle to Grave, edited by P.C. Burns, G. E. Sigmon (Mineralogical Association of Canada), vol. 43p. 337p (2013)

K. Nilsson, O. Roth, M. Jonsson, J. Nucl. Mater. 488, 123–128 (2017)

Commissariat à l’énergie atomique (CEA), Nuclear fuels. A Nuclear Energy Division Monograph. Gif-sur-Yvette, 147 pp. (2009)

J. Arborelius, K. Backman, L. Hallstadius, M. Limbäck, J. Nilsson, B. Rebensdorff, G. Zhou, K. Kitano, R. Löfström, G. Rönnberg, J. Nucl. Sci. Tech. 43, 967–976 (2006)

A.R. Massih, Effects of additives on uranium dioxide fuel behavior. SSM Report 21, 62 (2014)

H.U. Zwicky, J. Low, J.E. Ekeroth, Corrosion studies with high burnup light water reactor fuel, SKB TR-11-03, Svensk Kärnbränslehantering AB, (2011)

M. Trummer, B. Dahlgren, M. Jonsson, J. Nucl. Mater. 407, 195–199 (2010)

R. Pehrman, M. Amme, O. Roth, E. Ekeroth, M. Jonsson, J. Nucl. Mater. 397, 128–131 (2010)

S. Nilsson, M. Jonsson, J. Nucl. Mater. 410, 89–93 (2011)

C.M. Lousada, M. Trummer, M. Jonsson, J. Nucl. Mater. 434, 434–439 (2013)

Y. Kumagai, A. Barreiro Fidalgo, M. Jonsson, J. Phys. Chem. C 123, 9919–9925 (2019)

P. Kegler, M. Klinkenberg, A. Bukaemskiy, G.L. Murphy, G. Deissmann, F. Brandt, D. Bosbach, Materials 14, 6160 (2021)

A.C. Maier, P. Kegler, M. Klinkenberg, A. Baena, S. Finkeldei, F. Brandt, M. Jonsson, Dalton Trans. 49, 1241 (2020)

E. Ekeroth, M. Jonsson, J. Nucl. Mater. 322, 242–248 (2003)

M. Jonsson, E. Ekeroth, O. Roth, MRS Proc. 807, 77 (2003)

V.L. Vinograd, A.A. Bukaemskiy, G. Modolo, G. Deissmann, D. Bosbach, Front. Chem. 9, 705024 (2021)

A.B. Fidalgo, M. Jonsson, J. Nucl. Mater. 514, 216–223 (2019)

N. Rodríguez-Villagra, O. Riba, A. Milena-Pérez, J. Cobos, L. Jimenez-Bonales, S. Fernández-Carretero, E. Coene, O. Silva, L. Duro, J. Nucl. Mater. 568, 153880 (2022)

Acknowledgments

This project has received funding from the European Union's Horizon 2020 research and training programme of the European Atomic Energy Community (EURATOM) (H2020-NFRP2016/2017) under grant agreement No. 755443 (DisCo). Open Access funding was enabled and organized by Projekt DEAL.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kegler, P., Neumeier, S., Klinkenberg, M. et al. Accelerated dissolution of doped UO2-based model systems as analogues for modern spent nuclear fuel under repository conditions. MRS Advances 8, 255–260 (2023). https://doi.org/10.1557/s43580-023-00544-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43580-023-00544-y